All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

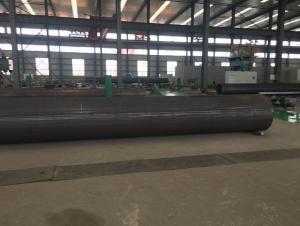

- - Welded Steel Pipe

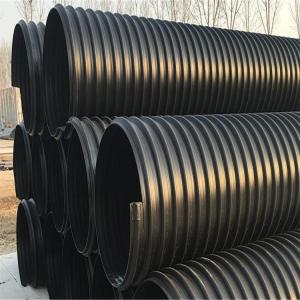

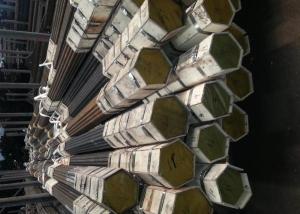

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Q & A

What are the benefits of using hollow steel tubes in mechanical engineering applications?

There are several benefits of using hollow steel tubes in mechanical engineering applications. Firstly, hollow steel tubes have a high strength-to-weight ratio, making them ideal for applications where weight is a concern but strength is still required. Additionally, the hollow shape provides inherent stiffness and stability, allowing for efficient load-bearing capabilities. Hollow steel tubes also offer versatility in design, as they can easily be shaped, bent, or welded to meet specific requirements. Furthermore, the hollow interior of the tubes allows for the passage of fluids, gases, or electrical wiring, making them suitable for applications where internal routing is necessary. Overall, the use of hollow steel tubes in mechanical engineering applications provides a combination of strength, lightweight construction, versatility, and efficient load-bearing capabilities.

Are hollow steel tubes used in the production of musical instruments?

Yes, hollow steel tubes are commonly used in the production of musical instruments. They are often utilized in the construction of brass instruments, such as trumpets and trombones, where they form the main tubing of the instrument. The use of hollow steel tubes allows for the creation of specific pitches and tones when air is passed through them, contributing to the unique sound produced by these instruments.

What are the considerations for fatigue resistance in hollow steel tubes?

There are several considerations for fatigue resistance in hollow steel tubes. First, the material used for the tube should have high strength and good fatigue properties to withstand cyclic loading. The tube's geometry, such as wall thickness and diameter, should be optimized to enhance its fatigue resistance. Additionally, the tube's surface finish and any potential defects, such as welds or seams, should be carefully inspected and controlled to minimize stress concentrations that can lead to fatigue failure. Finally, proper design and engineering practices, including understanding the expected loading conditions and applying appropriate safety factors, are crucial to ensure the fatigue resistance of hollow steel tubes.

Wholesale Hollow Steel Tubes from supplier in India

Whether you are in the construction, infrastructure, or manufacturing industry, we have the right Hollow Steel Tubes to meet your specific requirements. Our products are sourced from reputable manufacturers, ensuring high-quality standards and reliable performance.

Our sales team is dedicated to providing exceptional customer service and prompt responses to all inquiries. We understand the importance of timely delivery, and we work closely with our logistics partners to ensure that your orders are delivered on time and in perfect condition.

In addition to sales, we also offer comprehensive quotations tailored to your project specifications. Our team of experts will analyze your requirements and provide you with competitive pricing options, helping you make informed decisions that align with your budget and project goals.

Technical support is another key aspect of our services. Our team of engineers and technical experts are available to assist you in selecting the right Hollow Steel Tubes for your applications. Whether you have questions about material properties, design considerations, or installation methods, we are here to provide you with accurate and reliable information.

We take pride in our commitment to customer satisfaction and strive to build long-term partnerships with our clients. By choosing us as your supplier for Hollow Steel Tubes in India, you can expect exceptional products, reliable services, and expert advice every step of the way.

Contact us today to discuss your Hollow Steel Tubes requirements and let us help you find the perfect solution for your projects.

Our sales team is dedicated to providing exceptional customer service and prompt responses to all inquiries. We understand the importance of timely delivery, and we work closely with our logistics partners to ensure that your orders are delivered on time and in perfect condition.

In addition to sales, we also offer comprehensive quotations tailored to your project specifications. Our team of experts will analyze your requirements and provide you with competitive pricing options, helping you make informed decisions that align with your budget and project goals.

Technical support is another key aspect of our services. Our team of engineers and technical experts are available to assist you in selecting the right Hollow Steel Tubes for your applications. Whether you have questions about material properties, design considerations, or installation methods, we are here to provide you with accurate and reliable information.

We take pride in our commitment to customer satisfaction and strive to build long-term partnerships with our clients. By choosing us as your supplier for Hollow Steel Tubes in India, you can expect exceptional products, reliable services, and expert advice every step of the way.

Contact us today to discuss your Hollow Steel Tubes requirements and let us help you find the perfect solution for your projects.