All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

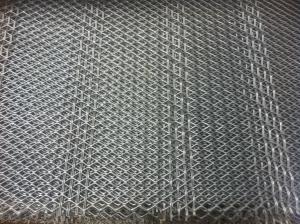

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Q & A

Can a welded steel pipe be used for structural applications?

Yes, a welded steel pipe can be used for structural applications. Welded steel pipes are commonly used in construction projects for structural purposes, such as supporting buildings, bridges, and other structures. The welded joints provide strength and durability, making them suitable for various structural applications.

What is the difference between shielded metal arc welding and submerged arc welding for welded steel pipe?

Shielded metal arc welding (SMAW) and submerged arc welding (SAW) are two different welding processes used for joining steel pipes.

SMAW, also known as stick welding, involves the use of a coated electrode that melts and forms a protective shield around the weld pool. This process is performed manually, and the welder has direct control over the welding parameters. SMAW is versatile and can be done in various positions, making it suitable for welding steel pipes of different sizes and shapes.

On the other hand, SAW is an automated welding process where an electrode is continuously fed into the joint, and a granular flux covers the weld zone. The arc is submerged beneath the flux layer, protecting it from atmospheric contamination. SAW is typically used for large-scale welding operations and is highly efficient due to its high deposition rates. It is commonly used for welding long, straight sections of steel pipes.

In summary, the key difference between SMAW and SAW for welded steel pipes lies in the welding method and the level of automation. While SMAW is a manual process that provides versatility, SAW is an automated process that offers high efficiency and is more suitable for large-scale pipe welding operations.

What are the factors that affect the fluid velocity in welded steel pipes?

There are several factors that can affect the fluid velocity in welded steel pipes. Some of the key factors include the diameter of the pipe, the length of the pipe, the roughness of the pipe's inner surface, the viscosity of the fluid, and the flow rate of the fluid. Additionally, factors such as the presence of bends or elbows in the pipe, as well as any restrictions or obstructions in the pipe, can also impact the fluid velocity.

What are the factors that affect the pressure rating of a welded steel pipe?

The factors that affect the pressure rating of a welded steel pipe include the thickness and quality of the steel, the weld integrity and quality, the diameter and length of the pipe, the temperature and type of fluid being transported, and the operating conditions such as pressure variations and external forces. These factors collectively determine the maximum pressure that the welded steel pipe can safely handle.

How is the pressure rating of welded steel pipe determined?

The pressure rating of welded steel pipe is determined by several factors, including the material's tensile strength, wall thickness, and the design and construction standards followed during manufacturing. These factors are taken into consideration to ensure the pipe can withstand the pressure it will be subjected to without failure or leakage.

Wholesale Welded Steel Pipe from supplier in Bolivia

With our strong market presence in Bolivia, we have established a solid reputation for delivering high-quality Welded Steel Pipe products. Our team of experts is dedicated to providing exceptional customer service, ensuring that your specific requirements are met with precision and efficiency.

Whether you are in need of standard or custom-made Welded Steel Pipe products, we have the capabilities to meet your demands. Our extensive product portfolio includes various specifications, sizes, and grades of Welded Steel Pipe, ensuring that we can cater to a wide range of applications in different industries.

In addition to supplying top-notch products, we also offer comprehensive sales, quotation, and technical support services. Our experienced sales team is committed to understanding your needs and providing tailored solutions that align with your project requirements. Through our quotation services, we strive to offer competitive prices without compromising on quality.

Moreover, our technical support services aim to assist you throughout the entire project execution process. Whether you require guidance on product selection, installation, or maintenance, our team of experts is readily available to provide valuable insights and recommendations.

As a subsidiary platform of CNBM, a Fortune Global 500 company, we have the advantage of accessing a vast network of resources and expertise. This enables us to provide comprehensive procurement solutions, ensuring that all your Welded Steel Pipe needs are met efficiently and effectively.

With years of market development experience in Bolivia, we have gained invaluable knowledge and insights into the local industry. This positions us as the ideal partner for successful project execution, as we understand the unique challenges and requirements of the Bolivian market.

At our company, we are committed to delivering exceptional products and services, exceeding your expectations every step of the way. Contact us today to discuss your Welded Steel Pipe needs in Bolivia and let us be your trusted partner for all your procurement requirements.

Whether you are in need of standard or custom-made Welded Steel Pipe products, we have the capabilities to meet your demands. Our extensive product portfolio includes various specifications, sizes, and grades of Welded Steel Pipe, ensuring that we can cater to a wide range of applications in different industries.

In addition to supplying top-notch products, we also offer comprehensive sales, quotation, and technical support services. Our experienced sales team is committed to understanding your needs and providing tailored solutions that align with your project requirements. Through our quotation services, we strive to offer competitive prices without compromising on quality.

Moreover, our technical support services aim to assist you throughout the entire project execution process. Whether you require guidance on product selection, installation, or maintenance, our team of experts is readily available to provide valuable insights and recommendations.

As a subsidiary platform of CNBM, a Fortune Global 500 company, we have the advantage of accessing a vast network of resources and expertise. This enables us to provide comprehensive procurement solutions, ensuring that all your Welded Steel Pipe needs are met efficiently and effectively.

With years of market development experience in Bolivia, we have gained invaluable knowledge and insights into the local industry. This positions us as the ideal partner for successful project execution, as we understand the unique challenges and requirements of the Bolivian market.

At our company, we are committed to delivering exceptional products and services, exceeding your expectations every step of the way. Contact us today to discuss your Welded Steel Pipe needs in Bolivia and let us be your trusted partner for all your procurement requirements.