All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

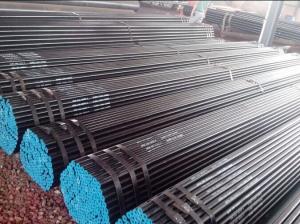

- - Seamless Steel Pipe

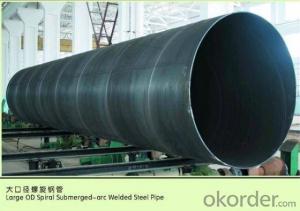

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Q & A

Can welded steel pipes be used for oil and gas laboratories?

Yes, welded steel pipes can be used for oil and gas laboratories. Welded steel pipes are commonly used in various industries, including oil and gas, due to their strength, durability, and resistance to corrosion. They are suitable for transporting liquids and gases, making them ideal for laboratory applications in the oil and gas sector.

What is the difference between electric resistance welding and submerged arc welding for welded steel pipe?

Electric resistance welding (ERW) and submerged arc welding (SAW) are two different methods used for welding steel pipes.

ERW involves passing an electric current through the edges of the steel strip or plate, causing them to heat up and form a weld. This process is fast and efficient, making it suitable for both small and large diameter pipes. ERW pipes generally have a smooth surface finish.

On the other hand, SAW involves creating an arc between a continuously fed wire electrode and the steel pipe. The arc is shielded by a layer of granular flux, which protects the weld and prevents atmospheric contamination. SAW is commonly used for thicker pipes and produces deep penetration welds. The flux layer also acts as a protective coating, making SAW pipes more resistant to corrosion.

In summary, the main difference between ERW and SAW for welded steel pipe lies in the method of welding and the resulting characteristics of the finished product. ERW provides a smooth surface, while SAW offers deeper penetration and enhanced corrosion resistance.

How are welded steel pipes joined together during installation?

Welded steel pipes are joined together during installation by using welding techniques such as electric resistance welding, submerged arc welding, or high-frequency induction welding. These methods involve heating the ends of the pipes and applying pressure to create a strong bond between them.

How are welded steel pipes manufactured?

Welded steel pipes are manufactured through a process known as welding. This involves heating the edges of steel plates or coils to their melting point and then joining them together using various welding techniques such as arc welding, electric resistance welding, or fusion welding. The welded seam is then inspected for quality and the pipe is further processed, including sizing, straightening, and cutting, to meet the desired specifications and standards.

How is the dimensional accuracy of welded steel pipe ensured?

The dimensional accuracy of welded steel pipe is ensured through careful inspection and adherence to industry standards. This involves using precise measurements and techniques during the welding process to ensure the correct alignment and dimensions of the pipe. Additionally, advanced quality control methods such as non-destructive testing and dimensional checks are employed to verify the accuracy of the finished product.

Wholesale Welded Steel Pipe from supplier in Bangladesh

Our team of experts is dedicated to delivering high-quality Welded Steel Pipe products that meet your specific requirements. Whether you need pipes for structural purposes, water supply systems, or oil and gas pipelines, we have the expertise to assist you.

We understand the importance of timely delivery and cost-effective solutions. Our strong network of suppliers allows us to source products efficiently and deliver them to you on time. Additionally, we offer competitive pricing, ensuring that you get the best value for your investment.

In addition to our sales services, we also provide comprehensive technical support. Our team is proficient in assisting with product selection, providing technical specifications, and offering guidance on proper installation and maintenance. We strive to ensure that you have all the necessary information and support to make informed decisions and successfully complete your projects.

At our company, customer satisfaction is our top priority. We believe in building long-term relationships with our clients based on trust, reliability, and exceptional service. Our dedicated customer support team is always available to address any inquiries or concerns you may have.

Contact us today to discuss your Welded Steel Pipe requirements in Bangladesh. Let us be your trusted partner in procuring high-quality products that meet your specific needs.

We understand the importance of timely delivery and cost-effective solutions. Our strong network of suppliers allows us to source products efficiently and deliver them to you on time. Additionally, we offer competitive pricing, ensuring that you get the best value for your investment.

In addition to our sales services, we also provide comprehensive technical support. Our team is proficient in assisting with product selection, providing technical specifications, and offering guidance on proper installation and maintenance. We strive to ensure that you have all the necessary information and support to make informed decisions and successfully complete your projects.

At our company, customer satisfaction is our top priority. We believe in building long-term relationships with our clients based on trust, reliability, and exceptional service. Our dedicated customer support team is always available to address any inquiries or concerns you may have.

Contact us today to discuss your Welded Steel Pipe requirements in Bangladesh. Let us be your trusted partner in procuring high-quality products that meet your specific needs.