All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Q & A

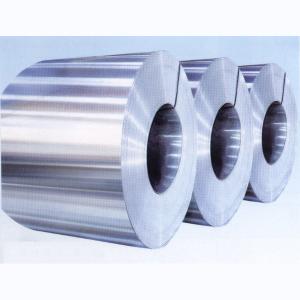

How are aluminum coils used in the production of aluminum sound barriers for transportation?

Aluminum coils are used in the production of aluminum sound barriers for transportation by being formed into panels or sheets that make up the structure of the sound barriers. These coils are first unrolled and then cut into desired lengths or shapes before being shaped into panels or sheets. The aluminum coils provide the necessary strength, durability, and corrosion resistance required for sound barriers, ensuring they can effectively reduce noise pollution near transportation infrastructure.

What are the key differences between extruded and rolled aluminum coils?

The key differences between extruded and rolled aluminum coils lie in their manufacturing processes. Extruded aluminum coils are produced by pushing or pulling the aluminum through a die to create the desired shape and size. This process results in a more uniform and consistent product, with enhanced mechanical properties. On the other hand, rolled aluminum coils are produced by passing the aluminum through a series of rollers, which gradually reduce the thickness and shape the material. This method allows for greater flexibility in terms of coil length and width, making it suitable for various applications. Additionally, rolled aluminum coils can exhibit a slightly rougher surface compared to extruded coils.

What is the difference between aluminum and steel coils?

The main difference between aluminum and steel coils lies in their composition and properties. Aluminum coils are made from aluminum, a lightweight and corrosion-resistant metal. They are commonly used in industries where weight is a concern, such as aerospace and automotive. Steel coils, on the other hand, are made from steel, which is stronger and more durable than aluminum. Steel coils are widely used in construction, manufacturing, and infrastructure projects. Additionally, steel is magnetic, making it suitable for applications that require magnetic properties.

Can aluminum coils be used in the food and beverage industry?

Yes, aluminum coils can be used in the food and beverage industry. Aluminum is a safe and hygienic material that is resistant to corrosion and has excellent heat conductivity. It is commonly used for food packaging, beverage cans, and cooking utensils. Aluminum coils are often utilized in food processing equipment, refrigeration systems, and air conditioning units, ensuring efficient heat transfer and maintaining food safety standards.

Wholesale Aluminum Coils from supplier in Bangladesh

We are a Aluminum Coils supplier serving the Bangladesh, mainly engaged in the sale, quotation, and technical support services of various Aluminum Coils products in the Bangladesh region. We are a subsidiary platform of the Fortune Global 500 company CNBM, able to provide you with one-stop Aluminum Coils procurement services in the Bangladesh. Not only do we have a wide range of Aluminum Coils products, but after years of market development in the Bangladesh, we can also provide valuable experience for your projects.