Worm soft sealed butterfly valve DN25-DN800

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 9999 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

PART NAME AND MATERIAL

| Parts name | Materail |

| Valve body | Grey iron, ductile iron |

| Seat | PTFE |

| Disc | Ductile iron |

| Axle | Carbon steel ,Stainless steel |

THE PRESURE RANGE AND USAGE

| Type | Nominal pressure(MPa) | Testing pressure | Suitable temperature(°C) | Suitable medium | |

| Strength (water) (MPa) | Enclose (Water) (MPa) | ||||

| D71X-10 | 1.0 | 1.5 | 1.1 | ≤80℃ | Water |

| D371X-10 | |||||

| D71X-16 | 1.6 | 2.4 | 1.8 | ||

| D371X-16 |

THE MEASURMENTS OF THE d71x butterfly valve

|

Quick Details

Structure: Butterfly

Pressure: Low Pressure

Power: Manual

Material: Casting

Temperature of Media: Normal Temperature

Media: Water

Port Size: DN40-DN1200

Place of Origin: China (Mainland)

Wafer type: butterfly valve Packaging & Delivery

Packaging Details: Plactic bag+Paper cover+Plywood cases

Delivery Detail: Within 20 days

Specifications

Wafer type lined butterfly valve

1.Design standard:ISO,BS,API

2.DN40-DN1200

3.PN10/PN16/PN25

4.Center lined disc

Wafer type lined butterfly valve

Technical Data

DN40-DN1200mm PN1.0-1.6MPa

General Design:ISO 5752 / BS 5155 / API 609

Body: Cast Iron, Ductile Iron, Carbon Steel, Stainless Steel

Seat: EPDM, PTFE, NBR,Viton

Stem: Stainless Steel, Steel,

Disc: Ductile Iron with Nickel Coating,Ductile Iron with Nylon Coating, Stainless Stee 304/316l, Alu-Bronze,Duplex steel

Flange Connection:DIN,ANSI,JIS,BS

Product Features

Wafer type flanged body style fit between FF or RF flanges

PTFE bushing ensure the maximum shaft support and centralized alignment

360°polished disc assures positive on-off

Hard-Backed Cartridge seat or Edge-Boot seat

The pin,spline or square connection are all available

Universal ISO 5211 mounting pad.

- Q:Whenever sports cars are referred, people talk in terms of 'valves'. ex: v8, v12 etc. What does this all mean? Also they sometimes say that a v8 makes a great noise. why? How does the number of valves effects the performance? Many thanks.

- When talking about car engines, references such as v4, v6, v8, v10 and v12 are not for the number of valves. it is for the number of cylinders. The more cylinders that an engine has, the more fuel it consumes and most of the time, the more horsepower it can make. There are exceptions to this though. Regarding the noise of the engine, i would agree that a v8 sounds very good when it is roaring. Valves are actually the openings for fuel to get into the cylinders and the exhaust to come out from. Most modern engines have two valves for incoming fuel and two valves for the exhaust making a total of four valves per cylinder. hope that clears it for you

- Q:What is the electric butterfly valve? Please, great God!

- The output signal is stable and reliable for a long time. The valve has an electric node, which is drawn out to the control center by signal line, and the signal line voltage is 12V. In fact, the valve is open and closed, there is a signal to the consumer control center, easy to monitor, the valve in addition to the electric node, with the ordinary valve is not much difference, there are also signal butterfly valve.

- Q:Three eccentric hard sealing butterfly valve, why not fit in the end of the pipe?

- The sealing ring will hold up. It does not fit in with the flange end of the pipeline, this addition is the most common and convenient pipeline after purge and easily add pipeline.

- Q:e.g. a patient with a prosthetic aortic valve and a patient with a prosthetic mitral valve. Also, can you get stenosis of mechanical valves or just tissue grafts?Thanks!

- mechanical okorder /

- Q:Classification of telescopic butterfly valve

- (1) Central sealed butterfly valve(2) single eccentric sealed coal valve;(3) double eccentric sealed butterfly valve(4) three eccentric sealed butterfly valve (1) soft sealing butterfly valve.1) the sealing pairs are made of non-metallic soft materials, which are made of non-metallic soft materials.2) the sealing pair is made of metal hard material and is made of non-metallic soft material.(2) metal hard sealing butterfly valve. The sealing pair is made of metal hard material and is made of metal hard material. (1) forced sealing butterfly valve;1) elastic sealing butterfly valve. The pressure of the valve seat, seat, or plate is produced when the seal is closed by the pressure from the valve

- Q:How is the lug butterfly valve connected to the flange?

- When installing, pay attention to the butterfly plate. The sealing ring between the flange face and the butterfly valve is tightened. After clamping, it can be tightened.

- Q:In the pipeline attached building Atlas 05S502, in the middle of a water meter and check valve, the two sides are divided into two butterfly valve, want to ask why to arrange this way, what is the role of the two butterfly valve?

- Check the water gauge and check valve on both sides to facilitate the maintenance and replacement of water meter and check valve.

- Q:What's the difference between cut-off valve, gate valve and butterfly valve? What's the difference in the working principle?

- Stop valve, leak small, gate valve, leak big, butterfly valve switch fast

- Q:Are fire fighting signal valves and signal butterfly valves the same thing?

- The same nature: both can open and close, there is also information back fed.Signal valves are collectively referred to as signal butterfly valves.

- Q:How do hydraulic butterfly valves work?

- Butterfly valve hydraulic drive device working principle1. manual operationWhen the hydraulic system suddenly fails, the valve can not move when the butterfly plate at any stop. Then, shaking the manual device, the guide block guide block in front of the manual shaft together with the driving shaft end, the cogging and drive shaft spline manual corresponding to the slot. Then, by dialing the driving device, the dial is shifted to the left end, and the transmission spline is connected with the manual shaft by a gear sleeve (the driving device is provided with a limit for preventing the tooth sleeve from jumping up), and the crank is disengaged from the hydraulic cylinder to disengage the hydraulic cylinder. Then turn the manual device and use the manual device to realize the disc movement.2. hydraulic operationWhen the hydraulic system returns to normal operation, the actuating device needs to be operated by hand. First, adjust the hydraulic cylinder to its initial state (0 digits) or at any position. Then manually adjust the opening of the disc to the position corresponding to the cylinder stroke (by observing whether the mark on the gear sleeve is in accordance with the mark on the crank, and judge the position of the disc and the cylinder). Then pull the gear sleeve and engage the spline on the crank by poking the driving device. Then fix the shift to prevent jumping. At this point, start the hydraulic system to restore fluid flow.

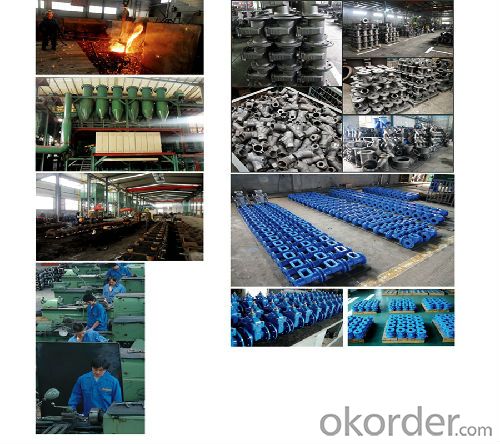

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Worm soft sealed butterfly valve DN25-DN800

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 9999 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords