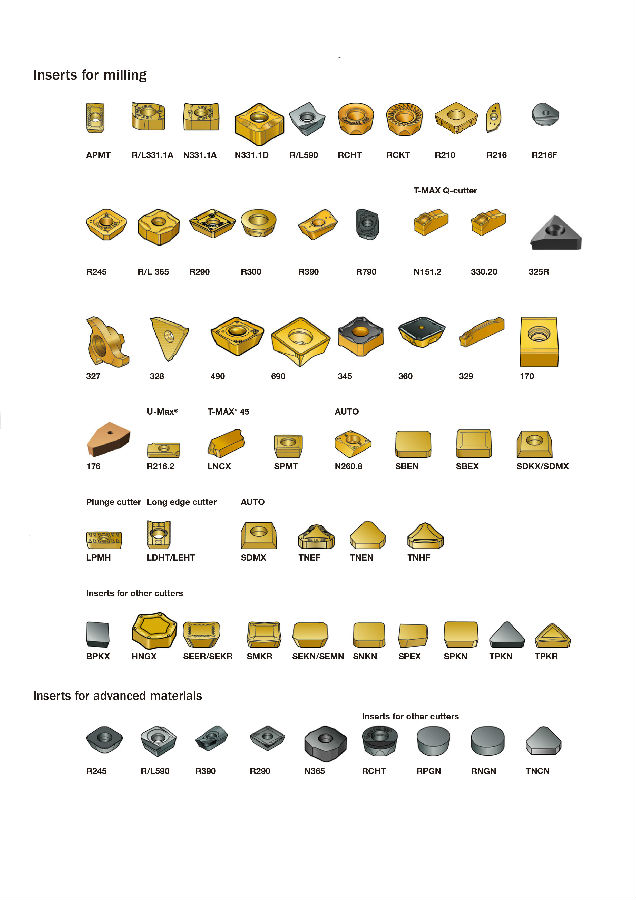

tungsten carbide inserts for cutting tool

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 pc

- Supply Capability:

- 90000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Information

- pure tungsten carbide material, recycling material is available

- Size of the inserts:OD limited crabide to 400 mm,thickness above 2mm

- Manufacturering carbide products including TC ball,bar material,wortle,strips,tips,dies,milling cutters,scraper blades,rods,inserts and so on.

- Factory price,manufacturing irregular shape according to your inserts' drawing

Packaging

1,soft foam to prevent the surface being scratched in one small carboard boxes, several small boxes in one larger hard carboard with fills to avoid a slope, besides hard carboard is easy to load and transport

2, we can also arrange packaging according to your special requirements or discuss

3,product code on cardboards instead of any company information such as logo to keep deal information secret and beneficial to customs clearance

Shipping

There are three ways to be choose, as follows:

- International Express: UPS,TNT,DHL

- Port transportation: all ports

- We delivery products according to customer’s requirements and paid by buyer after the destination confirmation

- take insurance for the goods according to contract

Our Service

- ISO , BV certificate and sound testing equipment to assure the quality

- Professional advice for the application problems, we accept return of goods with quality problems or discuss

- Survey Email of products usage will be sent timely to listen your feedback,our aim is trying to make everyone of our customers satified!

- Q:What is the method of welding the carbide blade on the blade?

- We'll brazing it with flame! Oxygen and acetylene 1 give the car knife red with borax!

- Q:The tip of the tool tip

- The tip of the blade determines the smooth finish of the cutting workpiece, and the tip of the blade has different functions, and it is necessary to grind a small circular arc to the tip of the blade.

- Q:What are the car knives made of?

- Three faces: the front face A gamma-cutting the surface of the outflow. A alpha, the surface of the transition surface. The second knife face A alpha - the surface opposite the processed surface. Two edges: main cutting edge and side cutting edge; Tip: main cutting edge and side cutting edge. The cutting part of the lathe consists mainly of the following parts: the front face A gamma-cuttings along the outward surface. A alpha, the surface of the transition surface. The second knife face A alpha - the surface opposite the processed surface. Main cutting edge - the edge of the knife facing the front edge of the main blade. Side cutting edge - the blade of the knife facing the front of the knife. The geometrical Angle of the tool is determined in the reference frame of a certain plane, which is usually orthogonal frame reference frame, the normal frame reference frame and the assumption working plane frame reference frame

- Q:Does the grinder work with the grinder or the universal grinder?

- First of all, it is best to use a grinding wheel grinder for a sharpener, and it is better to grind a knife. As to the car technology is the knife, the precision, the degree of proficiency is usually these, the most basic.

- Q:I use acetylene oxygen to weld a common lathe blade. Why does the blade keep cracking

- Welded structure of cutting tool should have enough rigidity, enough rigidity is the appearance of the maximum allowable size, and USES high strength steel grade and to ensure that the heat treatment. Carbide blade should be fixed firm, for example, cemented carbide welding blade should have enough degree of fixation, it is to rely on groove and welding quality to ensure that, generally speaking, according to the shape of blade and the cutting tool geometry parameter choice blade groove shape. It is necessary to inspect the blade before the carbide blade is welded to the blade, and the blade must be inspected first. Hard alloy welding surface must not have serious carburizing layer, at the same time should also will carbide blade surface and cutter bar set of dirt to clean, to guarantee the welding. In order to ensure the welding strength, choose the suitable solder. During the welding process, good moisture and liquidity should be guaranteed, and the bubbles shall be eliminated, and the welding and alloy welding surfaces shall be fully in contact with the welding phenomenon. Welding flux choice: borax industry, can be used in the drying furnace shall be carried out before use dehydration processing, then crushed, sieve to remove mechanical impurities in again. Use mesh compensation pads. For example: in the welding of titanium high low cobalt fine alloy and welding of long and thin blade, in order to reduce welding stress, and sheet thickness of 0.2 ~ 0.2 mm can be used or mesh aperture 2 ~ 3 mm spacer mesh compensation on welding.

- Q:Hole in the inner port knife? The hole in the bore is the same

- The main cutting movement is finished by the workpiece, the centrifugal force of the workpiece is large, the machining ellipticity and the turings are easy to produce.

- Q:Excuse me, I now want to weld a hard alloy car knife need which material, beg the concrete method

- Apply the pole to the grinding wheel, the metal luster, ground level, easy welding. First heated the cutter bar, 700 degrees (just a dark red) and a few borax, continue to heat and copper wire, copper wire at this time of melt, evenly spread out on the welding of the copper, not too thick, laying copper flat, otherwise the cutting head is bad. Leave the torch and sprinkle a little bit of borax. Use tweezers put good, the alloy tool bit heating cutter and cutter bar juncture place, this place is on the tool holder, (part) is not on the tip of this is for the sake of tool holder and tool bit heated at the same time, when the tool holder and tool bit reaches 800 degrees Fahrenheit, put the copper electrode, then copper electrode melt into the cutting head and the crevice tool rod, heat the torch around the cutting head shaking more, until the cutting head and the cutter bar to isothermal, cutting head completely floating on the cutter bar, welding is complete. Do not move at this time of tool holder, cutting head is out, wait about 15 seconds, copper sludge, the cutter and cutter bar in a heat insulation barrels containing vermiculite, slow cooling after about 4 hours, the temperature of the cooling to be able to use.

- Q:In the work of the car, the tip of the blade and the center of the workpiece have any impact on the workpiece roughness.

- A large diameter piece of work is a little bit shorter and it doesn't matter. When you have a very thin piece of diameter, you want to be as flat as possible

- Q:Who knows what equipment and tools to weld hard alloys on knives and milling knives.

- According to the difference of the protective atmosphere, it can be divided into reduced gas and inert gas furnace brazing. The reductive gas is usually H2 or CO, not only to avoid the oxidation of the workpiece during the heating process, but also to reduce the oxidation film on the surface of the workpiece, which can help to moisten the solder. Inert gas Ar, N2, and He, is commonly used in demand for gas purity is higher, generally in more than 99.99%, even after dehydration before gas charging (silica gel, sulfuric acid) DNA (titanium sponge) device. The workpiece is usually placed in a container and heated brazing in a flowing gas. The use of inert gas is higher than the safety of the reduced gas. Heating temperature, heat preservation time and cooling rate are the main process parameters. When heating temperature higher than 900 ℃, the hardness of cemented carbide are significantly reduced. The hardness of hard alloy can also be reduced when the insulation is too long. After welding, it should be cooled slowly to prevent cracking

- Q:What type of car can be made of the car with a smooth surface

- No. 45 will use the alloy knife of its own. This kind of knife speed cannot be too high, too high can burn a knife. If the workpiece is not too large, it can also be done with the type of high speed that the blade can be used for the tool's performance.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

tungsten carbide inserts for cutting tool

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 pc

- Supply Capability:

- 90000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords