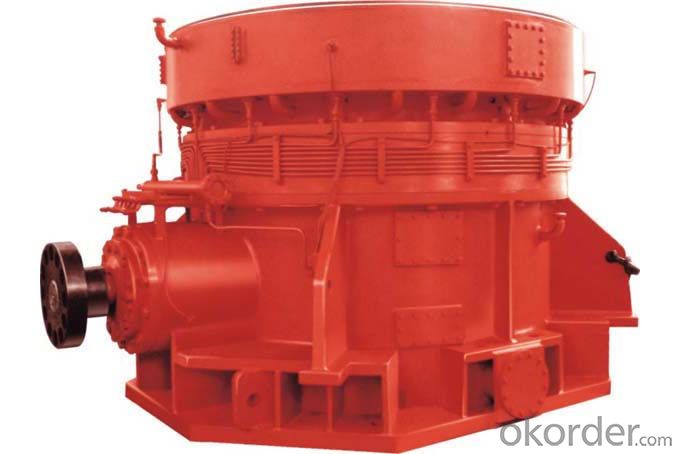

High Quality and widely used Reducer

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 1 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

The reducer is an independent component composed of a gear drive, a worm drive, and a gear-worm drive enclosed in a rigid housing. It is often used as a deceleration drive between the prime mover and the working machine. It plays a role in matching the speed and transmitting torque between the prime mover and the working machine or actuator, and is widely used in modern machinery.The reducer is an independent component composed of a gear drive, a worm drive, and a gear-worm drive enclosed in a rigid housing. It is often used as a deceleration drive between the prime mover and the working machine. It plays a role in matching the speed and transmitting torque between the prime mover and the working machine or actuator, and is widely used in modern machinery.The reducer is an independent component composed of a gear drive, a worm drive, and a gear-worm drive enclosed in a rigid housing. It is often used as a deceleration drive between the prime mover and the working machine. It plays a role in matching the speed and transmitting torque between the prime mover and the working machine or actuator, and is widely used in modern machinery.

- Q:Is the synchronous motor not communicating? Why do you say that brushless dc is a type of synchronous motor? Exclude o

- Brushless dc motor is not a smooth direct current, but pulse square wave. Like synchronous motors, speed is associated with frequency of square waves.

- Q:What is the speed of the general motors

- The motor synchronous speed is n = 60f/p n speed f power frequency p electromagnetism log. Common motor speed is 960, 1400, 2800 RPM. More.

- Q:How does dc motor change ac motor

- But between dc motor and ac motor can't convert each other, this is because their manufacturing process and machine structure is different, the design from the start then can not be changed, unless you have taken apart the motor to have done

- Q:Who made the world's first ac motor?

- In 1867, the Belgian character ram was made into an improved alternator. Scientists in 1886, the Croatian American origin tesla made two phase winding type ac asynchronous motor model, and in 1888 and developed the principle of the tesla coil, and in 1891 made the tesla coil's patent, which laid a foundation for alternating current (ac) of the remote transmission. It can be said that Edison and tesla, the former is not the inventor of the direct current (dc), the latter is not the inventor of the alternating current (ac), the later this misconception is that from the current war at the end of the 19th century, because two people a stick to dc, another promote communication, and let people think they are dc and ac inventor (baidu encyclopedia "tesla" entry is written).

- Q:Do you start the coils when you are communicating?

- In addition, the resistance split-phase motor (such as thermal resistor start refrigerator motor), after the start, resistance value is very big, can think of the coil is power, does not work.

- Q:Can a converter drive a normal three-phase ac motor?

- First introduce the frequency conversion motor: look from the appearance, the most obvious is characterized by frequency conversion motor have a single cooling fan, and a cooling fan has a special connection box. The cooling fan needs to be connected to the power supply alone, so that no matter how often the motor works, it will not affect the heat dissipation of the motor.

- Q:What is the braking mode of ac motor? What are the characteristics

- The brake method of ac motor has three main kinds: 1, mechanical brake The braking method of turning off the motor rapidly after the electric motor is turned off. Like electromagnetism brake, friction plate brake.

- Q:When the ac servo motor is turned off, the rotor shaft is tight

- If there is no brake device, it indicates that the load is not installed properly, which can cause rotational difficulty. Solution: loosen the load and turn the motor separately. The structure of ac servo motor can be divided into two parts, the stator part and the rotor part. The structure of the stator is basically the same as the stator of the rotating transformer, and in the stator iron core, there is also a two-phase winding of the Angle of 90 degree Angle. One group is the excitation winding, the other is the control winding, the ac servo motor is a two-phase ac motor. When ac servo motor is used, the excitation voltage Uf is applied at both ends of the excitation winding, and the control voltage is applied on both ends of the winding winding. When the stator winding is combined with the voltage, the servo motor will soon turn. Going into the field winding and control winding current to produce a rotating magnetic field in the motor, the rotating magnetic field to determine the steering motor, when any one of favorite on winding voltage inverting, the direction of the rotating magnetic field is changed, the direction of the motor is also changing.

- Q:The difference between the permanent magnet motor and the permanent magnet synchronous motor

- The permanent magnet motor USES direct current, and there is a commutator. Permanent magnet synchronous motor with ac, no commutator.

- Q:The voltage must be, what is the speed of the motor What is the rated voltage of the motor in alternating current? (with winding winding number)

- The number of wires in a coil is not necessarily the number of turns, but the number of wires in a coil is equal to the number of turns of the coil when the number of wires is equal to one. Have the following relations: the number of a coil of wire around along with all the number x number of turns of stator per slot number of wires is to point to in a single layer winding, each slot wire number is equal to the number of turns; In the double layer winding, the number of leads per slot is twice the number of melons and the number of turns.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

High Quality and widely used Reducer

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 1 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches