Usg PVC Ceiling Tiles - Common Printing/Hot Stamping/Laminated

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Applications:

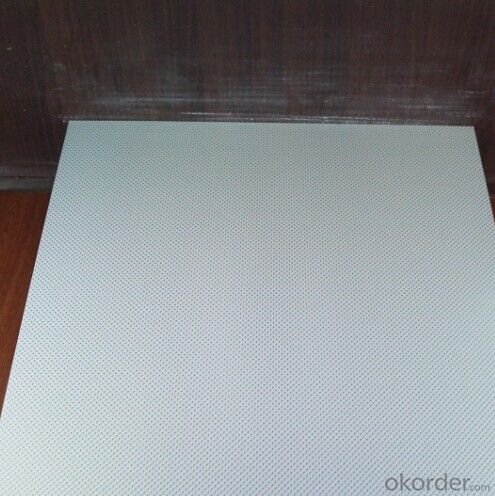

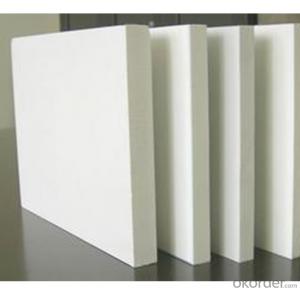

size: 60cm*60cm*7mm

pvc: 40%-45%

weight: 2.5kg/2.7kg/2.9kg

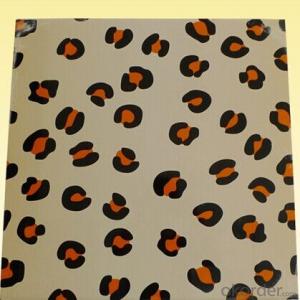

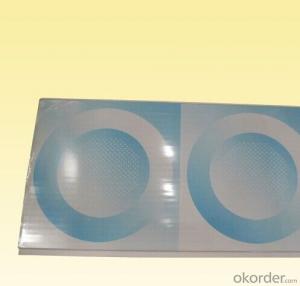

common printing/hot stamping/laminated

Product Advantages:

(1) Easy to install and clear

(2) Variety of colors and patterns or as your request

(3) High intensity, resist erosion, auti aging

(4) Fireproof, waterproof, environment friendly

(5) High quality, good service and good price

(6) Aesthetic and durable

Main Product Features:

1)Glossy PVC Panel (most common type)

2)Sub-glossy PVC Panel (Natural surface handing)

3) High-glossy PVC Panel (high-light surface handling)

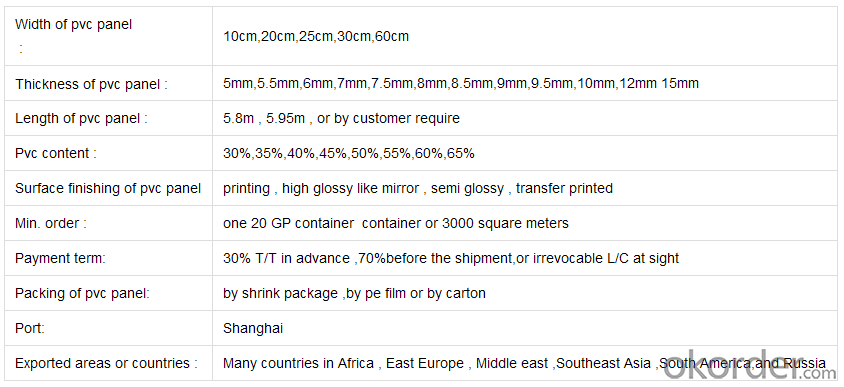

Product Specifications:

Images:

- Q: Pvc crystal plate 1.6mm per square meter with multiple

- The proportion of PVC crystal plate is 1.35 g / cm3, 1.6mm weight per square meter should be 100 cm × 100 cm × 0.16 cm × 1.35 g / CM3 = 2160 g.

- Q: In the MDF posted a layer of PVC, is the plastic plate? But the plastic board is surrounded by the edge of the ah, who knows the name of this plate ah?

- MDF, also known as fibreboard, is made of wood fiber or other plant fiber as raw material, urea-formaldehyde resin or other suitable adhesive made of man-made sheet. According to their density, divided into high density board, MDF, low density board. Dust board due to the soft impact resistance, but also easy to reprocess, in foreign countries is a good material for the production of furniture, but because the country on the high density board standards than the international standard several times lower, so the density board in China, the use of quality Still need to be improved.

- Q: , Pvc board, wood keel ceiling, contractors, not packing materials, buy their own wooden screws, mainly to do the bathroom, toilet kitchen, open at 4 meters above, how much money a square meter can do

- Fifteen dollars per square, the premise is flat top. Southern words about twenty or so. Specifically your description of your area

- Q: Production of PVC foam board of raw materials are what ah? What is the role of ah?

- PVC resin: This is the most important raw materials, foam substrate, the production of PVC foam sheet generally use P-700-type PVC resin, the processing of its gelation speed, processing temperature is relatively low, product quality and density Easy to control. In the production of leather foam PVC sheet, in order to improve product quality, strict control of product density and thickness fluctuations, more use of P-700-type vinyl PVC resin. In the production of free foam PVC sheet, from the lower production costs to consider, there are many manufacturers using calcium carbide P-700-type PVC resin

- Q: How to quickly tear off the protective film on the PVC board

- Heated with a hair dryer

- Q: It is said that the PVC board is divided into several categories, their respective types of what is the difference between the use, I would like to ask, who can tell me, thank you,

- A. PVC board - anti-static pvc board Anti-static pvc board atlas anti-static pvc board (anti-static PVC board) Features: High hardness and high scratch resistance; 6 to 10 of the surface resistance of 10 to 10 ohm ohm, with excellent anti-static function, impact resistance and chemical resistance of the outstanding performance; beautiful appearance, very smooth and smooth; More than 73%. Flammability rating is ul-94: v-0. Colour: Transparent, smoke, milky white, gray and so on. application: Equipment cover, dust-free box, test fixture and so on. Two PVC board - PVC hard board Rigid PVC extruded sheet is produced from the Austrian Cincinnati Mila Kelang company with the world's most advanced flat CM80 cone twin screw extrusion production line production. Product quality first-class, the color is generally gray and white, can also be produced according to customer needs PvC color hard board, its bright colors, beautiful and generous. Product thickness limit: 25mm or less. Product width: 900mm, 1300mm, 1500mm. Features: The quality of the implementation of the product GB / T13520-1992. With excellent chemical stability, corrosion resistance, hardness, high strength, anti-ultraviolet (anti-aging), fire-retardant (with self-extinguishing), reliable insulation, smooth surface smooth, non-absorbent non-deformation, easy processing Features. use: The product is an excellent thermoformed material that replaces some of the stainless steel and other corrosion resistant synthetic materials.

- Q: Pvc floor ok how is it compared to solid wood flooring?

- Pvc floor is the first use of medical infusion bag material - PVC as raw material processing made of. Non-toxic, non-formaldehyde, safe green materials. Pvc floor ok ok Again its advantages are as follows: Long life: the surface after a special nv treatment has a super wear characteristics, life is more than 3 times the traditional wood flooring. Good elasticity: good elasticity has a very good cushioning effect. Play to protect the elderly, the child's safety. Especially in schools, kindergartens, airports and other places where traffic is high. Pvc floor ok ok Color pattern rich: pvc floor has a rich variety of patterns and colors. Especially the color of the sheet pvc floor, his pattern is more diversified, a variety of different patterns of color, realistic imitation wood, marble pattern, carpet pattern and other patterns. Choose from a variety of options Other features: non-slip, fire retardant, waterproof, noise and noise and other characteristics.

- Q: What is the treatment before the color, what kind of paint or paint to color? Satisfied with points

- PVC can own color, do not have their own

- Q: PVC ceiling plate how to disassemble

- First of all, you have to observe the buckle board, the general edge of the last piece is not a block, then this piece is not the whole piece is the last piece, but also to first remove a piece, Hold down the last piece of the hand to the wall hard push, to 2 side to push, light push side is not enough, you push this piece in the end, you will find and another side of the office has been divorced, and then You can directly win, and the second plate will remove the screws, the screws in the middle of the wood, directly screw down on it, the screw down and then pull down this board also down, and then Repeatedly, the top is removed!

- Q: Would you like to take a still life with a PVC background board, or is it good for the background paper? Not the product. I want to learn to shoot still life, do not know which is better? Which comparison is used? There is this background paper and PVC background when not put away, with the time out and then put out on the static stage can it? Will it be wrinkled? Which will be convenient to accommodate? Thank you

- PVC background board

Send your message to us

Usg PVC Ceiling Tiles - Common Printing/Hot Stamping/Laminated

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords