Tractor Truck 35T SINOTRUK-JWZ 4x2(ZZ4181M3611C)

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 15 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description for 35T SINOTRUK-JWZ 4x2(ZZ4181M3611C)

Complete Vehicle Kerb Mass(kg) 6600

Maximum authorized total mass (kg) 18000

Maximum authorized towed total mass(kg) 3,200,035,200

Dimension Parameter External Dimensions(mm) Length 5950 Width 2490

Height 307,037,003,870

wheelbase(mm) 3600

Minimum Ground Clearance(mm) 294

Performance Parameter Maximum Speed(km/h) 93

Economical Speed(km/h) 75

Maximum Gradeability(%) 30

Turning diameter(m) 7.03

Features for 35T SINOTRUK-JWZ 4x2(ZZ4181M3611C)

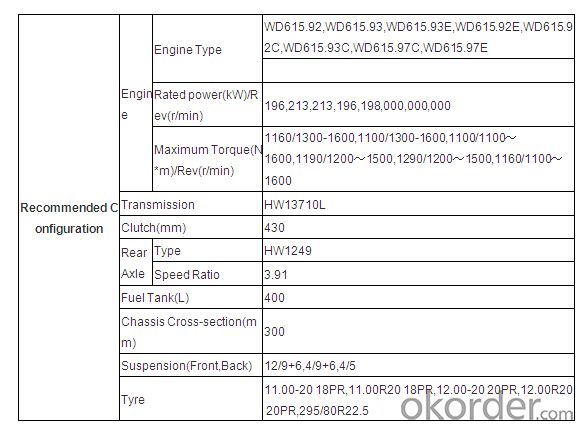

Recommended Configuration Engine Engine Type WD615.92,WD615.93,WD615.93E,WD615.92E,WD615.92C,WD615.93C,WD615.97C,WD615.97E

Rated power(kW)/Rev(r/min) 196,213,213,196,198,000,000,000

Maximum Torque(N*m)/Rev(r/min) 1160/1300-1600,1100/1300-1600,1100/1100~1600,1190/1200~1500,1290/1200~1500,1160/1100~1600

Transmission HW13710L Clutch(mm) 430 Rear Axle Type HW1249

Speed Ratio 3.91

Fuel Tank(L) 400

Chassis Cross-section(mm) 300

Suspension(Front,Back) 12/9+6,4/9+6,4/5

Tyre 11.00-20 18PR,11.00R20 18PR,12.00-20 20PR,12.00R20 20PR,295/80R22.5 18PR

Specifications for 35T SINOTRUK-JWZ 4x2(ZZ4181M3611C)

Pictures for 35T SINOTRUK-JWZ 4x2(ZZ4181M3611C)

FAQ for 35T SINOTRUK-JWZ 4x2(ZZ4181M3611C)

Q:what is recommended Configuration Engine Engine Type A:WD615.92,WD615.93,WD615.93E,WD615.92E,WD615.92C,WD615.93C,WD615.97C,WD615.97E

Q:How many tyres for option?

A:tyre11.00-20 18PR,11.00R20 18PR,12.00-20 20PR,12.00R20 20PR,295/80R22.5 18PR

- Q: no i cannot hear any machinery, no fans?

- After all the philosophy and speculations are finished, we're still left with just words, metaphors. They are our tools for understanding the world, but it's always well to remember they have only a nodding acquaintance with reality.

- Q: Agency to test military draft machinery?

- Read the article carefully. People don't have anything to fear of a military draft, just as long as conservatives control the military. There are plenty of liberals calling for a draft, but I doubt they will get far. This is the same type of rhetoric we saw during the election. Kerry trying to scare people about a House bill that was going to reinstate the draft. Liberals were behind that bill and conservatives thought it was nonsense. Liberals are behind the most recent bill to reinstate the draft as well, but that looks about as dead as the last one. It would take an act of congress to bring the draft back, and that ain't goin' to happen!

- Q: About the marketing strategy of construction machinery industry

- The art of war said, "those who do not seek the overall situation, can not seek a domain, do not seek a domain, can not seek the overall situation", and emphasizes the importance of the thoroughness of strategic activities. The thoroughness of marketing planning mainly comes from the detailed knowledge of the market, the ability of insight into the market and the rich planning experience. The action plan should be practical, operational and flexible

- Q: Name2activitieswhereitis necessaryto reducefriction [in machinery] betweenmovingparts &tellhowwecouldreduceit.

- 1. Bearings - you need to reduce the heat so you lubricate with oil. 2. Shaft holders - heat again and oil again - usually one of the materials is softer than the other so it wears quicker, usually the cheaper of the two materials. Sometimes the parts are coated to reduce friction.

- Q: This is a sentence from a novel which I do not understand its meaning. What is a whirling machine? and does it relate to scratching eyebrow? Or it is just an idiom? The setting of the story is around 1940.

- The teacher(?) is implying that the children are stupid. That a machine (the brain) has to labour just to tell them to scratch their eyebrows!

- Q: For example:- Have you repaired the machinery?- Yes, I have repaired (it / them).

- It is a word like furniture, equipment, information, etc. no plural form exists as they are non-count noun, so IT is the pronoun to use.

- Q: I personally believe it is in little ways. 1.) Advertisements are continually cheapening human interaction. Example: the man who is talking about finding his queen and we think he is talking about a woman but no he is talking about a sofa. 2.) Face to face interaction has become less and less important in society. We are all on our phones, watching TV or on our computers sending text messages or on facebook. 3.) Everywhere you look people are not looking at the person they are talking to, they are too busy with gadgets. I mean who here has been annoyed becuase the person they were talking to was texting?So basically my question is, Do you think technology is good or bad for humans?

- Yes actually I believe it is also. I went from calling my mother like 6 times a day to sending her and my little sister IM's on Yahoo Messenger, and hitting up their myspace's. We do it more and more since she moved from where I am in Massachusetts to Georgia. Also, I Google everything. A Dictionary, Thesaurus, Phone Book, even Bible I can look up all the information online.

- Q: Is there any way to gain pecks without weights or machinery, maby a technique, or just a simple way to exercise them without weights.thanks

- merely drink 1st Baron Beaverbrook grease... yet dont consume the 1st Baron Beaverbrook which will make you earnings weight everywhere else... oh, if its too warm to drink, you could look ahead to it to coach right into a paste and unfold it on your bagel

- Q: For my law and justice class, im defending a guy who took some medicine that was labeled Do not operate heavy machinery. One hour after taking the medicine, he drove to tacoma to pick up his daughter and got in a car accident. So, would a car be considered Heavy Machinery?

- What Is Heavy Machinery

- Q: Why are hydraulic systems used in machinery such as bulldozers and backhoes, while pneumatic systems are used for things like opening and closing bus doors?Please provide a lot of detail, and examples!

- Where Are Hydraulic Systems Used

Send your message to us

Tractor Truck 35T SINOTRUK-JWZ 4x2(ZZ4181M3611C)

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 15 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords