Titan Geogrids - Volume Production Manufacturer

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20000 m²

- Supply Capability:

- 50000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

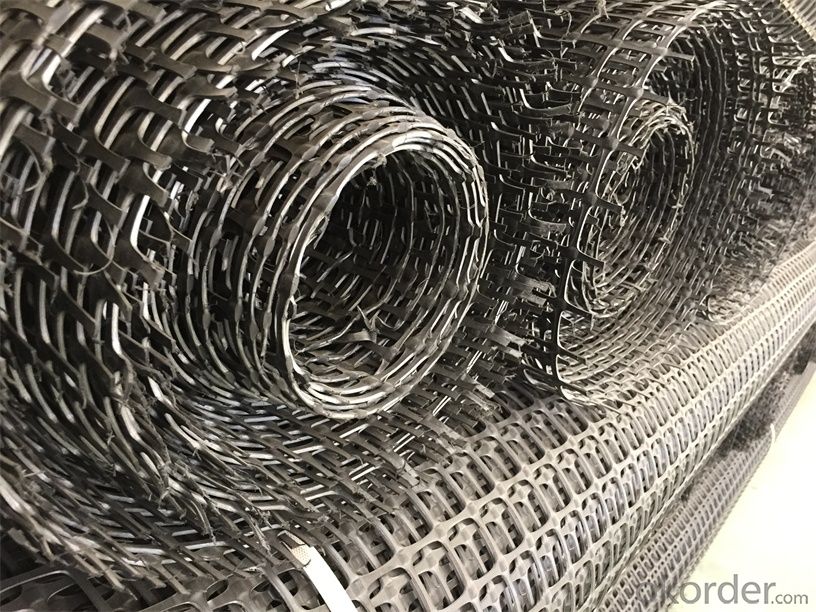

Fiberglass Geogrid Introduction:

Fiberglass geogrid is a kind of planar mesh material using alkali-free fiberglass yarn as base body and then coated with high quality modified asphalt. It is warp knitted with oriental structure which gives full play of yarn strength and improves its mechanical property to make the product high tensile, tearing and creep-resistant. Moreover, the composite property of coating with asphalt makes full protection of the fiberglass matrix and greatly improves its wear and shear resistance. All the advantageous functions make the product have a good performance in pavement strengthening, track cracking and solving difficulties of strengthening the bituminous pavement.

Fiberglass Geogrid Features:

1. Light weight, high tensile strength, high modulus, low elongation and good toughness.

2. Corrosion resistance, no long-term creep, long life span.

3. Good physical and chemical stability and good thermal stability.

4. Resistant to fatigue cracking, high-temperature track and low temperature shrinkage cracking.

5. Delaying and decreasing crack reflection.

Specifications | PET20-20 | PET30-30 | PET40-40 | PET50-50 | PET80-80 | PET100-100 | PET120-120 |

Elongation(%) | 10%~15% | ||||||

Vert Tensile strength(KN/m) | 20 | 30 | 40 | 50 | 80 | 100 | 120 |

Horiz Tensile strength(KN/m) | 20 | 30 | 40 | 50 | 80 | 100 | 120 |

Grid(mm) | 12.5×12.5 20×20 24.5×24.5 | ||||||

Width(m) | 1—6 | ||||||

Fiberglass Geogrid Application:

1. Road surface asphalt overlay construction engineering; Asphalt layers

reinforcement.

2. Converting old cement concrete road into composite road; Restraining

reflection cracking caused by block shrinkage.

3. Road extension; Preventing and controlling the cracking caused by new

and old combination and uneven settlement.

4. Treatment of the conjunction between tunnel and bridge or foundation.

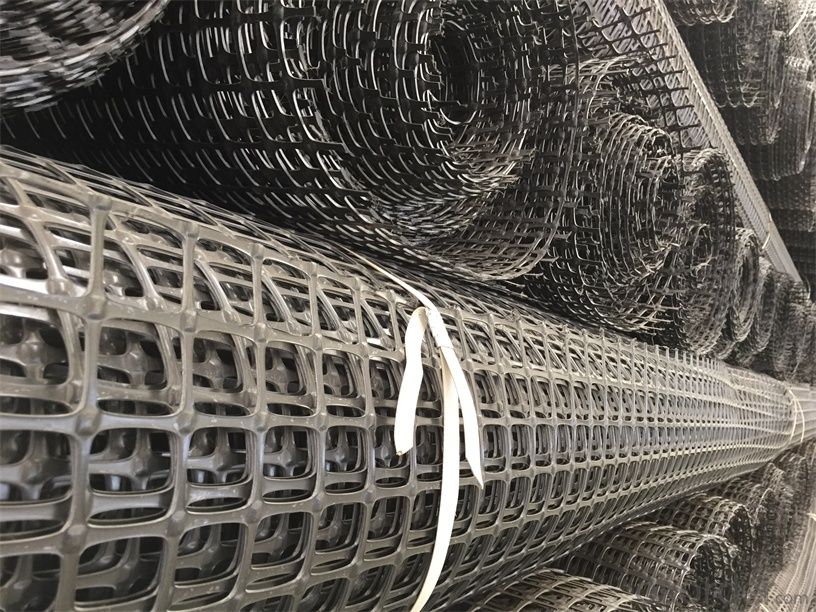

Packaging & Shipping:

FAQ:

1. How to order your geogrid ?

a) Tensile strength in warp & weft direction

b) Grid size

c) Roll Width and length

d) Quantity

2. What is the Payment term?

a) TT

b) LC AT SIGHT

c) cash

d) 30% contact value as deposit ,the blance 70% be paid after received the copy of bl .

3. Delivery time

a) 19-25 days after received your depsit .

4. What is MQQ ?

a) 2500 m2 as MQQ , we can also produce sample for you .

Welcome to send your inquiry to us, and if you have any question, we can also help you.

- Q: Can geogrids be used in ground stabilization for oil and gas facilities?

- Yes, geogrids can be used in ground stabilization for oil and gas facilities. Geogrids are commonly used to reinforce and stabilize soil in various applications, including the construction of oil and gas facilities. They provide additional strength to the ground, preventing soil erosion, improving load-bearing capacity, and enhancing overall stability.

- Q: Can geogrids be used in subgrade stabilization applications?

- Yes, geogrids can be used in subgrade stabilization applications. Geogrids are often used to reinforce and stabilize the soil in subgrade areas, improving their load-bearing capacity and preventing soil movement. By distributing the load across a larger area, geogrids help to reduce settlement and increase the overall stability of the subgrade.

- Q: What is the difference between a uniaxial and a biaxial geogrid?

- A uniaxial geogrid is designed to provide strength and stability in one direction, typically in the longitudinal axis. It is used to reinforce soil or other materials in applications such as road construction, retaining walls, and embankments. On the other hand, a biaxial geogrid is designed to provide strength and stability in both the longitudinal and transverse directions. It offers enhanced reinforcement capabilities and is commonly used in applications where multidirectional support is required, such as steep slopes, ground stabilization, and pavement systems.

- Q: Are geogrids resistant to biological clogging?

- Yes, geogrids are resistant to biological clogging. They are typically made from materials such as high-density polyethylene (HDPE) or polyester which are resistant to biological degradation. Additionally, geogrids have an open structure that allows for effective drainage and prevents the accumulation of organic matter that could lead to clogging.

- Q: Are geogrids effective in preventing soil erosion on hillsides?

- Yes, geogrids are effective in preventing soil erosion on hillsides. Geogrids are typically made from durable materials that reinforce the soil, providing stability and preventing it from being washed away by water or eroded by wind. By distributing the forces exerted on the soil, geogrids help to maintain its integrity and prevent erosion, making them a reliable solution for protecting hillsides against soil erosion.

- Q: How many square meters of steel plastic geogrid inspection

- The materials of the steel and plastic geogrid need to pass the factory certificate and the inspection report of the manufacturer, and the inspection batch shall be tested by 10 thousand square meters for the base number of 1 times.

- Q: How do geogrids improve the stability of shorelines?

- Geogrids improve the stability of shorelines by providing reinforcement and structural support to the soil or sediment. They are commonly used to prevent erosion and maintain the integrity of coastal areas. The geogrids act as a barrier that holds the soil in place, effectively reducing the impact of wave action and water currents. This reinforcement enhances the stability of the shoreline and helps to prevent the loss of soil or sediment, ultimately protecting the coastline from erosion.

- Q: Can geogrids be used in landfills?

- Yes, geogrids can be used in landfills. Geogrids are commonly used in landfill applications to reinforce slopes, stabilize soil, and improve overall stability and performance of the landfill structure.

- Q: What are the long-term effects of using geogrids?

- The long-term effects of using geogrids include improved soil stability and increased load-bearing capacity, leading to reduced soil erosion and enhanced durability of structures. Additionally, geogrids can contribute to long-lasting pavement performance, reduced maintenance costs, and extended lifespan of infrastructure projects.

- Q: What is the recommended overlap for geogrid installation?

- The recommended overlap for geogrid installation is typically 1 to 2 feet or 30 to 60 centimeters.

Send your message to us

Titan Geogrids - Volume Production Manufacturer

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20000 m²

- Supply Capability:

- 50000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords