Tinplate in Coils for Cans Packing in good quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t

- Supply Capability:

- 7000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Electrolytic Tin Plate Coils and Sheets for Foods Metal Packaging Description

Due to Tinplate packaging`s good seal, nature, dark, robustness and unique decorative metal charm, it has a wide range of coverage in the packaging container industry,and common international packaging varieties. With a variety of CC tinplate material, DR materials, chrome plated and constantly enrich and promotion and development of packaging products and technology, tinplate packaging has promoted with innovation.

Because of its strong antioxidant and diverse styles, beautifully printed, tinplate containers are very popular and loved by customers, and they are widely used in food packaging, pharmaceutical packaging, commodity packaging, instrumentation, packaging, industrial packaging and so on.

With the continuous improvement of tinplate printing technology and processing technology, tinplate packaging has developed more widely.

2.Main Features of the Electrolytic Tin Plate Coils and Sheets for Foods Metal Packaging

Appearance – Electrolytic Tin Plate is characterized by its beautiful metallic luster. Products with various kinds of surface roughness are produced by selecting the surface finish of the substrate steel sheet.

Paintability and printability – Electrolytic Tin Plates have excellent paintability and printability. Printing is beautifully finished using various lacquers and inks.

Formability and strength – Electrolytic Tin Plates have got very good formability and strength. By selecting a proper temper grade, appropriate formability is obtained for different applications as well as the required strength after forming.

Corrosion resistance – Tinplate has got good corrosion resistance. By selecting a proper coating weight, appropriate corrosion resistance is obtained against container contents. Coated items should meet 24 hour 5 % salt spray requirement.

Solderability and weldability – Electrolytic Tin Plates can be joined both by soldering or welding. These properties of tinplate are used for making various types of cans.

Hygienic – Tin coating provides good and non toxic barrier properties to protect food products from impurities, bacteria, moisture, light and odours.

Safe – Tinplate being low weight and high strength makes food cans easy to ship and transport.

Eco friendly – Tinplate offers 100 % recyclability.

Tin is not good for low temperature applications since it changes structure and loses adhesion when exposed to temperatures below – 40 deg C.

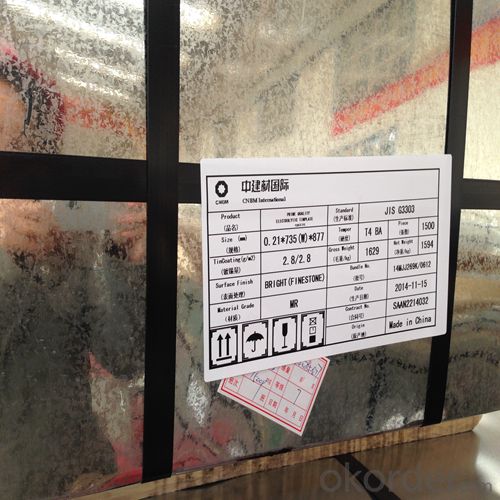

3.Electrolytic Tin Plate Coils and Sheets for Foods Metal Packaging Images

4.Electrolytic Tin Plate Coils and Sheets for Foods Metal Packaging Specification

Standard | ISO 11949 -1995, GB/T2520-2000,JIS G3303,ASTM A623, BS EN 10202

|

Material | MR,SPCC |

Thickness | 0.15mm - 0.50mm |

Width | 600mm -1150mm |

Temper | T1-T5 |

Annealing | BA & CA |

Coil Inner Diameter | 508mm |

Weight | 6-10 tons/coil 1~1.7 tons/sheets bundle |

Passivation | 311 |

Oil | DOS |

Surface | Finish,bright,stone,matte,silver |

5.FAQ of Electrolytic Tin Plate Coils and Sheets for Foods Metal Packaging

-What your tinplate material is used for ?

Tinplate is widely used for the packaging of products. Such as food cans,

beverage cans, pet cans, closures, general line cans and so on.

Printed Tinplate is offered!!

-How to place .an order or contact you ?

Please send us Email. we will give you a quick response in seconds .

- How is your quality ?

All our quality is prime even the secondary quality . We have many years experience

In this field with serious quality control standard . Advanced equipment, We welcome your visit to our factory .

- Q: How is tinplate coated?

- Tinplate is coated through a process called electrolytic tinning, where a thin layer of tin is deposited onto the surface of a steel sheet. This is achieved by immersing the sheet in an electrolyte solution and passing an electric current through it, causing tin ions to migrate and deposit onto the steel surface. This coating provides tinplate with corrosion resistance and enhances its appearance.

- Q: How can recycled tin cans be recycled?

- The broken material is separated by the air whirling sorting system, and the metal and nonmetal are separated from each other. Moreover, the whole system is equipped with a dust removing device to minimize the damage caused by dust pollution in the process of production.Tin tins, crushing machines, equipment and maintenance costs are low: equipment design is reasonable, well made, extending the service life of equipment, reducing the use and maintenance costs of equipment.

- Q: Why do tin tins rust easily when they are opened?

- The tinplate is of poor quality and the tin is not enough

- Q: What are the main applications of tinplate in the textile industry?

- Tinplate is commonly used in the textile industry for various applications such as packaging, labeling, and decorative elements. It is often used to create tinplate cans or containers for storing textile products, ensuring their protection and preservation. Tinplate is also utilized in labeling and branding, providing a durable and attractive surface for printed information. Additionally, tinplate can be formed into decorative elements like buttons or fasteners, adding aesthetic value to textile products.

- Q: How is tinplate tested for quality and durability?

- Tinplate is tested for quality and durability through a series of methods including visual inspection, chemical analysis, thickness measurement, and corrosion resistance assessment. These tests ensure that the tinplate meets the required standards and can withstand various environmental conditions and handling processes.

- Q: How is tinplate recycled?

- Tinplate is recycled through a process known as steel scrap recycling. First, the tinplate is collected and sorted. Then, it undergoes a shredding and melting process to separate the steel from other materials. The melted steel is purified and refined, removing any impurities. Finally, the purified steel is used to produce new tinplate products, completing the recycling cycle.

- Q: What are the main uses of tinplate?

- The main uses of tinplate include packaging food and beverages, manufacturing cans for aerosol products, creating decorative tin containers, and producing electrical equipment enclosures.

- Q: Are there any health concerns associated with tinplate?

- Yes, there are potential health concerns associated with tinplate. Tinplate is coated with a thin layer of tin, which can sometimes contain traces of lead. Prolonged exposure to lead can be harmful, especially for children and pregnant women. Additionally, if the tin coating is damaged or corroded, it can lead to the migration of other metals into food or beverages, which may pose health risks. It is important to ensure the quality and integrity of tinplate packaging to minimize potential health concerns.

- Q: Are there any limitations to using tinplate packaging?

- Yes, there are limitations to using tinplate packaging. One limitation is that tinplate can be prone to corrosion, especially in contact with certain types of food or liquids. Another limitation is that tinplate is not as flexible as other packaging materials, making it less suitable for certain product shapes or sizes. Additionally, tinplate packaging can be more expensive compared to alternatives like plastics or cardboard.

- Q: What are the common printing methods used on tinplate?

- The common printing methods used on tinplate include lithography, offset printing, and screen printing.

Send your message to us

Tinplate in Coils for Cans Packing in good quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t

- Supply Capability:

- 7000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords