Tesa Strong Masking Tape Temperature Resistance 60 Rubber

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 roll

- Supply Capability:

- 600 roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

·World Top 500 Enterprises

·Resistance to cold, heat and aging

·Best quality and competitive price

·SGS&ISO9001

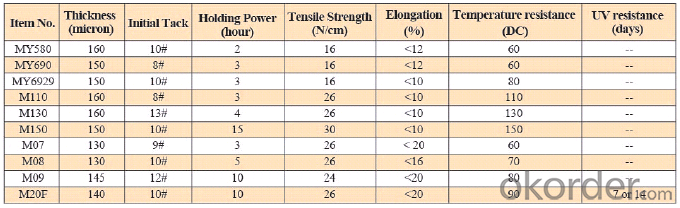

Typical Physical Reports of Masking Tape

Description

The Masking Tape is of crepe paper as the carrier, coating with rubber adhesive. It is excellent in flame retardant, high temperature stability, and anti-aging. It provides well insulation to various products.

The thickness of the tape can be customized.

Application

General purpose of Masking Tape: widely used for paint masking, furniture, shoe material production, automobile painting, light duty packaging etc.

Packaging & Delivery

Packaging Detail:

Log Roll: Length 1800mm; width according to customers’ requirements

Cut Roll: As per customer’s requirements

Delivery Detail: within 10-12 working days after receiving your deposit

Service

Sample of Masking Tape is available.

Your inquiry will be replied within 12 hours.

24 hours service

Well-trained & experienced sales representative are ready to answer you.

About us

CNBM International Corporation (CNBM International) is a state-owned company and we have sound business relations with clients from over 120 countries. Currently, we have wholly-owned overseas subsidiaries and branches in 5 countries with a view to realize localization, which also represents an essential progress in our globalization target. We have over twenty years experiences.

Welcome to contact us and visit the factory!

- Q: Can packaging tape be used for sealing packages with breakable items like ceramics?

- Yes, packaging tape can be used for sealing packages with breakable items like ceramics. However, it is important to ensure that the tape is applied properly to provide adequate support and protection for the fragile items. In addition to using packaging tape, it is recommended to use additional protective materials such as bubble wrap or foam padding to cushion the ceramics and minimize the risk of damage during transit.

- Q: Are there any regulations or standards for packaging tape?

- Yes, there are regulations and standards for packaging tape. These guidelines typically cover aspects such as strength, adhesion, durability, and safety. Organizations like ASTM International and the International Organization for Standardization (ISO) have developed standards to ensure that packaging tapes meet certain quality and performance requirements. Additionally, regulatory bodies in different countries may have specific regulations for packaging materials, including tapes, to ensure they are safe for use and compliant with applicable laws.

- Q: Can packaging tape be used for sealing packages with jewelry or valuables?

- Yes, packaging tape can be used for sealing packages with jewelry or valuables. Packaging tape is designed to provide a secure and durable seal, making it an excellent choice for ensuring the safety of your valuable items during shipping or transportation. It is strong and adhesive enough to securely close the package and protect the contents inside. However, it is always recommended to take additional precautions when shipping valuable items, such as using bubble wrap or cushioning material to provide extra protection.

- Q: How do I prevent packaging tape from curling up?

- To prevent packaging tape from curling up, there are a few things you can try: 1. Use a tape dispenser: Using a tape dispenser helps keep the tape straight and prevents it from curling. It also makes it easier to cut the tape to the desired length. 2. Apply tape evenly: When applying the tape, make sure to pull it tightly and apply it evenly across the surface. Avoid any wrinkles or bubbles as they can cause the tape to curl up. 3. Clean the surface: Ensure that the surface where you are applying the tape is clean and free from any dust, dirt, or moisture. These factors can interfere with the adhesive properties of the tape, causing it to curl. 4. Store tape properly: Proper storage of packaging tape is essential to prevent it from curling. Keep it in a cool, dry place away from direct sunlight. Extreme temperature changes can affect the tape's adhesive properties and lead to curling. 5. Choose good quality tape: Invest in high-quality packaging tape that is designed for long-term adhesion. Cheaper tapes often have lower quality adhesives that are prone to curling. 6. Use a heat source: If you are experiencing curling issues with the tape, you can try using a heat source like a hairdryer on a low setting. Gently heat the tape while applying it to help activate the adhesive and reduce curling. By following these tips, you should be able to prevent packaging tape from curling up and ensure a secure and professional-looking packaging.

- Q: Can packaging tape be used for sealing plastic storage bins?

- Indeed, plastic storage bins can be effectively sealed using packaging tape. The tape is specifically engineered to possess robust adhesion, making it an ideal choice for securing and sealing a wide range of materials, including plastic bins. Its dependable and long-lasting seal guarantees the security and protection of the bin's contents. Nevertheless, it is crucial to carefully and firmly apply the tape in order to achieve a tight seal. Moreover, it is advisable to utilize a high-quality packaging tape that is specifically tailored for the intended purpose to obtain the best sealing outcomes.

- Q: Is packaging tape resistant to moisture or humidity?

- Indeed, packaging tape typically exhibits resistance to moisture and humidity. The majority of packaging tapes incorporate materials like polypropylene or acrylic, renowned for their capacity to endure moisture and humidity. These tapes are purposefully crafted to establish a robust seal on boxes and packages, effectively thwarting the infiltration of water or moisture. Furthermore, packaging tapes frequently boast an adhesive that is meticulously formulated to retain its stickiness, even amidst humid conditions. Nevertheless, it is crucial to acknowledge that the extent of resistance may fluctuate depending on the precise type and caliber of packaging tape employed.

- Q: How do I prevent packaging tape from becoming too sticky?

- To avoid packaging tape becoming excessively sticky, there are several precautions you can take: 1. Keep the tape in a cool and dry location: Excessive heat and humidity often lead to the adhesive on packaging tape becoming stickier. It is important to store the tape in a cool and dry environment to maintain its proper consistency. 2. Prevent contact with dust and debris: Dust and debris easily adhere to the adhesive side of the tape, increasing its stickiness. Keep the tape away from dusty surfaces and ensure that the areas where you plan to apply the tape are clean and free from loose particles. 3. Utilize a tape dispenser: A tape dispenser aids in controlling the amount of tape you use and prevents excessive stickiness. It allows for a more precise application, ensuring that you do not use more tape than necessary. 4. Avoid excessive stretching of the tape: Stretching the tape excessively while applying it can cause it to become stickier. Apply the tape smoothly without pulling or stretching it too much, as this can activate the adhesive further. 5. Consider using low-tack or removable tape: If you frequently encounter problems with sticky packaging tape, you may consider using low-tack or removable tape. These types of tape have less aggressive adhesive properties and are easier to remove without leaving sticky residue. By following these guidelines, you can maintain the desired level of stickiness on your packaging tape and streamline your packaging process.

- Q: Can packaging tape be used for sealing plumbing or pipe fittings?

- No, packaging tape should not be used for sealing plumbing or pipe fittings. It is not designed for this purpose and may not provide a secure and durable seal. It is best to use appropriate plumbing sealants or tapes specifically designed for plumbing applications to ensure proper sealing and prevent any leaks.

- Q: What are the benefits of using tamper-evident packaging tape?

- Tamper-evident packaging tape offers several benefits for businesses and individuals alike. Firstly, it provides an additional layer of security by clearly indicating if a package has been tampered with. This helps to prevent theft, unauthorized access, or tampering of valuable or sensitive items during transit or storage. Furthermore, tamper-evident packaging tape enhances the trust and credibility of a business. By using such tape, companies can assure their customers that their products have not been tampered with and are delivered in their original state. This is particularly important for industries such as pharmaceuticals, food, and electronics, where ensuring product safety and integrity is crucial. Moreover, tamper-evident packaging tape also serves as a deterrent for potential tampering. The clear and visible markings on the tape act as a warning to would-be thieves or unauthorized individuals, discouraging them from attempting to tamper with packages. Another advantage is the ease of use and convenience that tamper-evident packaging tape offers. It can be applied quickly and easily to packages of various sizes and shapes, providing a reliable sealing solution that is resistant to tampering attempts. Additionally, the tape is usually designed to leave behind clear evidence of tampering, making it easy to detect if a package has been compromised. Lastly, using tamper-evident packaging tape can help businesses comply with regulatory requirements. Many industries have specific guidelines and regulations in place regarding product safety and security. By utilizing tamper-evident tape, companies can demonstrate their commitment to meeting these standards and ensure the integrity of their products throughout the supply chain. Overall, the benefits of using tamper-evident packaging tape include enhanced security, increased trust, deterrence of tampering, ease of use, and regulatory compliance. By investing in this simple yet effective sealing solution, businesses and individuals can protect their packages, ensure product integrity, and provide peace of mind to customers.

- Q: Is packaging tape safe to use on painted surfaces?

- Yes, packaging tape is generally safe to use on painted surfaces. However, it is recommended to test a small, inconspicuous area first to ensure that the tape does not damage or peel off the paint.

Send your message to us

Tesa Strong Masking Tape Temperature Resistance 60 Rubber

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 roll

- Supply Capability:

- 600 roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords