Scotch Packaging Tape Easy Tear - Tapes Packing Tape Aluminum Foil Tape Industry Tape PVC Wrapping Tape

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 m²

- Supply Capability:

- 10000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Structure of BOPP Tape Description

Widely used for cartom sealing and packing,light duty packing, bounding, holding and other office and household use.

2. Main Features of the BOPP Tape

Carton sealing & packing, Light duty packaging, bundling, holding, and other office & household use.

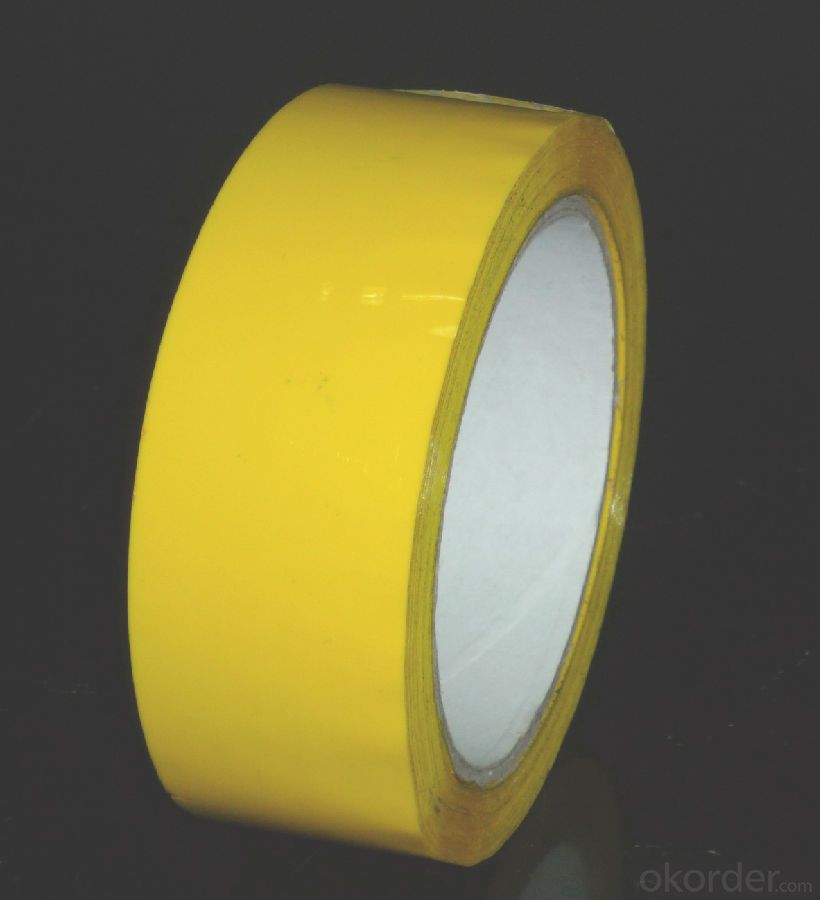

3. BOPP Tape Images

4. TYPICAL PHYSICAL PROPERTIES:

CONSTRUCTION:

Carrier: BOPP film

Adhesive: Water based acrylic adhesive.

TYPICAL PHYSICAL PROPERTIES:

Total Thickness (adhesives + carrier): 42 ± 1 um

Adhesive thickness:20 ± 1 um

Initial Tack: ³ 23#

180O Peel Adhesion (to steel): ³ 6.52 N /25mm

Holding Power: ³ 31 hrs

BP-50

Item No. | Carrier | Adhesive | Total | Initial | Peel Adhesion | Elongation |

BP-40 | BOPP film | water based acrylic | 40 micron | >18# | 0.5kgf/25mm | <180%< span=""> |

BP-45 | BOPP film | water based acrylic | 45 micron | >18# | 0.5kgf/25mm | <180%< span=""> |

BOPP film | water based acrylic | 50 micron | >20# | 0.5kgf/25mm | <180%< span=""> | |

BP-65 | BOPP film | water based acrylic | 65 micron | >24# | 7.88N/25mm | <180%< span=""> |

5.Advantage To Recommend:

We supply a wide range of products, which include double sided adhesive tape, masking tape, kraft tape, cloth tape, BOPP tape and so on.

Our biggest item is double side tape. Our double-sided adhesive tapes are with the carriers of tissue, PET, OPP, cloth, PE foam and EVA foam. And the adhesives involved are water based, solvent based and hot-melt acrylic adhesive.

According to different temperature resistances, we have two categories of masking tapes separately for general purpose and high temperature from 100°C to 160°C.

We also produce kraft tape, cloth tape and BOPP tape.

We have as our principle “Clients’ need comes first”. So we have a good variety of technical properties and sizes to meet with your different needs.

Our products enjoy popularity in markets because they have super quality with competitive price and good service.

Adhero is your ideal choice for excellent adhesive tapes and solutions.

6. FAQ:

1)What is the range of your products?

So far, we manufacture various kinds of double sided adhesive tape, masking tape, kraft tape and BOPP packing tape. To better meet your needs, we can also source other adhesive tapes for you if it is appropriate to do so.

2)What's the lead time for delivery?

We ensure you a prompt delivery of the goods. We do not stock any of the goods. The production cycle time of 1*20FCL is 2-3 weeks.

3)How many carriers does your double sided adhesive tapes have?

There are many carriers that our double sided adhesive tapes based on, which are tissue, PET, BOPP, PE foam, EVA foam.

4)Can Adhero accept the cooperation way of OEM?

Upon receipt of formal authorization, we can accept OEM processing.

5)What are the international commodity codes for these products?

HS Code: 48231900.

6)Are you offering only jumbos rolls or slit rolls as well?

We offer Jumbos, logs, and slit rolls. All different sizes are available.

7)What are the temperatures resistances of your masking tape?

we have two general kinds of masking tapes separately for general purpose 60°C and high temperature 100°C to 160°C.

8)Are you a manufacturer or just a trader?

We are a professional manufacturer.

9)How about the quality?

The quality is very good. We have large and advanced product line.welcome to visit our company.

- Q: Are there any specific instructions for reusing packaging tape?

- There exist specific instructions for reusing packaging tape. Here are several guidelines to adhere to: 1. Exercise caution when removing the tape from the package: Upon receiving a package, make an effort to delicately remove the tape in order to prevent tearing or damaging it. 2. Cleanse the tape: Should the tape possess any dirt, dust, or residue, it can be cleansed by gently wiping it with a moist cloth. Allow it to fully dry before reutilizing. 3. Assess the adhesive strength: Before reusing the tape, verify if the adhesive remains sufficiently strong to securely hold. If it has lost its stickiness or sustained damage, it is advisable to discard it and employ a fresh piece of tape. 4. Properly store the tape: To maintain the tape's quality for future use, store it in a cool, dry area away from direct sunlight. This will assist in preventing it from drying out or becoming brittle. 5. Utilize it for light to medium-duty tasks: Reused packaging tape may not possess the same strength as new tape, therefore it is most suitable for lighter to moderately demanding tasks. Avoid utilizing it for heavy items or applications necessitating a stronger adhesive. Bear in mind, while reusing packaging tape constitutes an excellent approach to waste reduction, it is crucial to prioritize functionality and security. If the tape becomes damaged or loses its adhesive strength, it is advisable to replace it with a new piece to ensure proper sealing of your package.

- Q: What are the benefits of using UV-resistant packaging tape?

- UV-resistant packaging tape offers numerous advantages. Firstly, it is specifically designed to endure prolonged exposure to sunlight, preventing it from deteriorating or degrading. This is particularly crucial when shipping or storing items outdoors or in areas with direct sunlight. With UV-resistant tape, packages can remain securely sealed for extended periods as it maintains its adhesive properties and structural integrity. Furthermore, UV-resistant packaging tape safeguards the contents of packages from UV ray damage. Sunlight can cause materials like paper, fabrics, or plastics to fade, discolor, or degrade. By utilizing UV-resistant tape, these items are shielded from the harmful effects of UV rays, preserving their quality and appearance. Moreover, UV-resistant packaging tape boasts long-lasting adhesion. Unlike regular tape, which may lose its stickiness over time when exposed to sunlight, UV-resistant tape is specially formulated to bond tightly and securely to various surfaces. This reliable adhesion minimizes the risk of packages opening or items sustaining damage during transit. Additionally, UV-resistant packaging tape provides peace of mind for both senders and recipients. By opting for tape that is resistant to UV rays, businesses and individuals can ensure that their packages arrive in the same condition they were sent, enhancing their professional image and customer satisfaction. This advantage is particularly vital when shipping valuable or delicate items that require extra protection. In conclusion, UV-resistant packaging tape offers enhanced durability, protection against UV damage, long-lasting adhesion, and increased confidence in package integrity. By selecting UV-resistant tape, individuals and businesses can effectively safeguard their packages and their contents, even when exposed to prolonged sunlight.

- Q: Are there different colors of packaging tape?

- In the market, one can find various colors of packaging tape. Although clear is the most commonly used color, there are also options like brown, white, black, and even vibrant choices such as red, blue, green, and yellow. The multiple colors of packaging tape serve different purposes. For instance, brown tape is frequently employed for sealing boxes and packages, white tape is commonly used for labeling or writing on, and colored tapes can be utilized for color-coding or enhancing the appearance of packages. The presence of diverse colors enables individuals and businesses to select the tape that best suits their specific requirements.

- Q: What kind of material is used in this kind of tape? What are its features? How are they made? And so on!The more detailed you write, the better!

- Look, there's no poison. Look at the sticky stuff above. What's that?

- Q: Is packaging tape resistant to extreme temperatures or weather conditions?

- Packaging tape is generally designed to be resistant to extreme temperatures and various weather conditions. However, the level of resistance may vary depending on the specific type and quality of the tape. Most packaging tapes are made from materials like polypropylene or PVC, which are known for their durability and ability to withstand different environmental factors. These tapes are often treated with special adhesives that can maintain their stickiness even in extreme temperatures or humid conditions. In terms of extreme temperatures, packaging tapes are typically designed to withstand a wide range of temperatures, including both low and high extremes. They can usually endure temperatures as low as -20 degrees Celsius or as high as 60 degrees Celsius without losing their adhesive properties or becoming brittle. Similarly, packaging tapes are engineered to be resistant to various weather conditions. They are designed to resist moisture, humidity, and UV radiation, which are common elements that can deteriorate the quality of the tape. This resistance ensures that the tape remains intact and effective, even when exposed to rain, snow, or direct sunlight. It is important to note that while packaging tape is generally resistant to extreme temperatures and weather conditions, prolonged exposure to such conditions can still impact its durability. Therefore, it is advisable to store and use packaging tape in a controlled environment whenever possible to ensure maximum effectiveness.

- Q: Does packaging tape have any specific certifications or standards?

- Yes, packaging tape can have specific certifications or standards. There are various organizations and standards that set guidelines for packaging materials, including packaging tape. One of the most common certifications for packaging tape is the International Organization for Standardization (ISO) certification. ISO sets standards for quality management systems, and packaging tape can be certified under ISO 9001:2015, which ensures that the product meets certain quality criteria. In addition to ISO certification, packaging tape can also adhere to specific industry standards such as ASTM International standards or European Union directives. ASTM International develops and publishes technical standards for a wide range of materials, including packaging tape. These standards ensure that the tape meets specific requirements related to strength, adhesion, and durability. Furthermore, some packaging tapes may have certifications related to their environmental impact. For example, certain tapes may be certified as recyclable, biodegradable, or made from sustainable materials. These certifications can be obtained from organizations like the Forest Stewardship Council (FSC) or the Sustainable Forestry Initiative (SFI), which promote responsible forestry practices. It is important to note that not all packaging tapes will have certifications or adhere to specific standards. However, if a packaging tape does have certifications or complies with certain standards, it signifies that the product meets certain quality, performance, or environmental criteria.

- Q: What are the considerations for using packaging tape on wooden surfaces?

- When using packaging tape on wooden surfaces, it is important to consider the type of tape being used and its adhesive properties. Opt for a tape specifically designed for use on wood to prevent any potential damage or residue. Additionally, ensure that the wooden surface is clean and dry before applying the tape to ensure proper adhesion. It is also advisable to test a small, inconspicuous area of the wood first to ensure that the tape does not cause any discoloration or damage.

- Q: Are there any specific instructions for reusing packaging tape?

- There exist specific instructions for reusing packaging tape. Here are several guidelines to adhere to: 1. Exercise caution when removing the tape from the package: Upon receiving a package, make an effort to delicately remove the tape in order to prevent tearing or damaging it. 2. Cleanse the tape: Should the tape possess any dirt, dust, or residue, it can be cleansed by gently wiping it with a moist cloth. Allow it to fully dry before reutilizing. 3. Assess the adhesive strength: Before reusing the tape, verify if the adhesive remains sufficiently strong to securely hold. If it has lost its stickiness or sustained damage, it is advisable to discard it and employ a fresh piece of tape. 4. Properly store the tape: To maintain the tape's quality for future use, store it in a cool, dry area away from direct sunlight. This will assist in preventing it from drying out or becoming brittle. 5. Utilize it for light to medium-duty tasks: Reused packaging tape may not possess the same strength as new tape, therefore it is most suitable for lighter to moderately demanding tasks. Avoid utilizing it for heavy items or applications necessitating a stronger adhesive. Bear in mind, while reusing packaging tape constitutes an excellent approach to waste reduction, it is crucial to prioritize functionality and security. If the tape becomes damaged or loses its adhesive strength, it is advisable to replace it with a new piece to ensure proper sealing of your package.

- Q: What are the alternatives to packaging tape for sealing packages?

- Sealing packages can be done using various alternatives to packaging tape. Here are a few choices available: 1. Gummed tape: Also known as water-activated tape, gummed tape is a well-liked substitute. It is created from paper or reinforced material and necessitates the use of water to activate the adhesive. Gummed tape forms a sturdy bond with the package and ensures a seal that is evident if tampered with. 2. Strapping: Strapping is commonly employed for securing heavy or bulky packages. It involves the use of plastic or metal straps to tightly hold the package together. Strapping can offer more security than tape, particularly for larger or irregularly shaped items. 3. Shrink wrap: Shrink wrap is a plastic film that can be wrapped around the package and sealed by applying heat. As the film shrinks, it conforms tightly to the shape of the package, ensuring a secure seal. Shrink wrap is frequently used for wrapping pallets or bundling multiple items together. 4. Adhesive labels: An alternative to tape for sealing packages is adhesive labels. These labels possess a strong adhesive backing that adheres to the package, guaranteeing a secure seal. They are particularly useful for small or lightweight items. 5. Twine or string: For lighter packages, twine or string can be used to secure the contents. Simply wrap the string around the package multiple times and tie it securely. Although this method may not be as strong as tape, it can be a cost-effective and environmentally friendly option. Ultimately, the selection of an alternative to packaging tape depends on the package's size, weight, and characteristics. Each option carries its own advantages and disadvantages, so it is important to consider the specific shipment requirements before making a decision.

- Q: Is packaging tape safe to use on plastic hangers?

- Yes, packaging tape is generally safe to use on plastic hangers. Packaging tape is designed to securely hold items together and can adhere well to various surfaces, including plastic. However, it's important to consider the type of plastic hanger you have and the purpose for which it is being used. While packaging tape may work well for temporarily holding clothes on a plastic hanger, it may leave residue or cause damage if left for an extended period. It's advisable to test a small area of the hanger first to ensure that the tape does not cause any harm or leave any marks. Additionally, if the plastic hanger is being used for displaying or storing delicate or valuable clothing, it may be better to opt for gentle alternatives such as fabric-friendly tape or non-adhesive hanger attachments.

Send your message to us

Scotch Packaging Tape Easy Tear - Tapes Packing Tape Aluminum Foil Tape Industry Tape PVC Wrapping Tape

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 m²

- Supply Capability:

- 10000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords