Strips of Aluminum for Industrial Cable & Wire - Aluminium Foil Strips

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 kg

- Supply Capability:

- 5000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Description of Aluminium Foil Strip Specially for Industrial Cable & Wire

*No joint-points per 1000m

*Free samples

*Waterproof and acid attacks

*Surface: With or without gloss/mat effect

*Printed: clear, fastness, non-fade in high-temperature heat seal process

2.Why you want to choose us?

We've been specialized in aluminium foil for more than ten years, we know this product very well, we know what is good, what is the market price.

3.Specification and Application of Aluminium Foil Strip Specially for Industrial Cable & Wire

Alloy: 8011, 1050, 1060, 1035, 1145, 1235, 1100, 1200

Temper: O, H22, H24

Thickness: 0.1-2.0mm

Width: 30-1000mm

Core I. D.: 3" or 6"

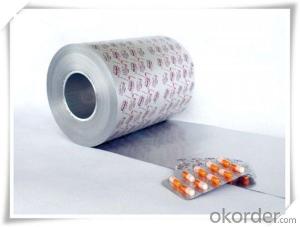

Application: Radio-shielding application of cables, wrapping and shielding application of cable. Cable foil is used as a skin for heat-insulating and electromagnetic shielding to provide high performance for Cable industry

Package: Standard Export wooden Case/Pallet

Remark: Specific requirement of alloy, temper or specification can be discussed at your request.

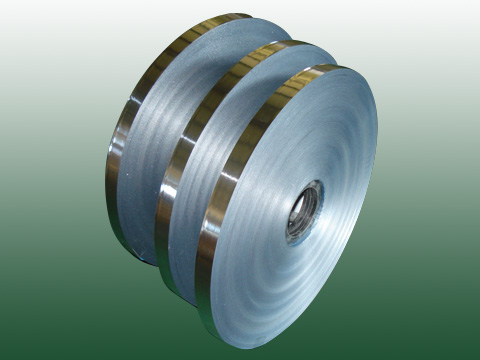

4.Pictures:

5.FAQ:

1) What is your delivery time?

Our regular production time is over 30 days, It depends on the order quantity also.

2) What is your payment term?

We accept T/T, LC at sight, Usance LC 30, 60, 90, 120, 180 DAYS.

3) What is your price structure?

Our foil price is based on Shanghai Metal Price(SMM), not LME, but we could offer LME+ Conversion for your reference.

4) What is your Delivery term?

We do FOB, CFR, CIF, we don't do DDP.

5) Could you offer sample?

We could offer sample as your requirement. A4 Size sample is free for you, for bigger roll sample, it depends on the coil weight.

- Q: This question asks for a list of various types of aluminum components used in the automotive industry.

- <p>Aluminum is widely used in the automotive industry due to its lightweight and high strength. Different types of automotive aluminum parts include engine components such as cylinder heads and blocks, transmission housings, suspension parts like control arms and knuckles, wheels and rims, body panels, and doors. Other applications include heat exchangers, radiators, and various brackets and structural components. The use of aluminum can significantly reduce the weight of vehicles, improving fuel efficiency and performance.</p>

- Q: This question seeks to understand the distinctions among various types of aluminum strips used in roofing and siding applications.

- <p>Aluminum strips for roofing and siding differ in terms of gauge, finish, profile, and coating. Gauge refers to the thickness, with lower numbers indicating thicker strips, offering greater durability. Finishes can be mill finish, anodized, or painted, with painted finishes offering color options and corrosion resistance. Profiles include standing seam, batten, and ribbed, each affecting aesthetics and water runoff. Coating thickness and type, such as Kynar 500 or Hylar 5000, impact weather resistance and lifespan. These factors determine the strip's suitability for specific climates, architectural styles, and budget considerations.</p>

- Q: What are the potential environmental concerns associated with the use of aluminum siding in construction?

- <p>While aluminum siding is lightweight and durable, there are environmental concerns associated with its production and disposal. The manufacturing process is energy-intensive and can emit greenhouse gases. Additionally, the extraction of bauxite, the primary source of aluminum, can lead to deforestation and habitat destruction. At the end of its life, aluminum siding can be recycled, which is beneficial, but improper disposal can still contribute to landfill waste. The environmental impact depends on the lifecycle management of the material, including responsible production, use, and recycling practices.</p>

- Q: Is it possible to safely install metal roofing without the help of a professional?

- <p>While it is possible to install metal roofing materials without professional assistance, it is not recommended for inexperienced individuals due to the complexity and potential risks involved. Metal roofing requires precise measurements, proper tools, and knowledge of building codes. Additionally, working at heights and handling sharp materials can be dangerous without proper safety training. It's safer and often more cost-effective in the long run to hire professionals who are skilled and insured for such work.</p>

- Q: This question asks for an explanation of the corrosion protection mechanism provided by aluminum strips.

- <p>Aluminum strips protect against corrosion through a process known as sacrificial anode cathodic protection. When aluminum is exposed to an electrolyte (like soil or water), it naturally forms a thin, protective oxide layer on its surface. This layer prevents further oxidation. In a galvanic cell, aluminum acts as the anode and corrodes preferentially, sacrificially protecting the cathode, which is usually a more noble metal like steel. The aluminum strip corrodes instead of the steel, thus preventing the steel from corroding. This method is effective because aluminum is more reactive than steel, and it corrodes at a slower rate once the initial protective layer is formed, making it a sustainable protection method.</p>

- Q: Is it possible to utilize recycled aluminum in a project as an alternative to new raw materials?

- <p>Yes, you can use recycled aluminum in your project instead of new raw materials. Recycled aluminum is not only more environmentally friendly but also often more cost-effective. It requires significantly less energy to produce compared to new aluminum, reducing carbon emissions. Additionally, using recycled aluminum can help conserve natural resources and reduce waste in landfills. However, it's important to consider the quality and purity of the recycled material to ensure it meets the specifications required for your project.</p>

- Q: This question asks if there are different types of aluminum with varying levels of electrical conductivity.

- <p>Aluminum, as a pure element, has a consistent electrical conductivity. However, its conductivity can be affected by the presence of impurities or alloying elements. In general, the higher the purity, the better the conductivity. Alloys like 1100 aluminum (99.00% pure) have the highest conductivity among aluminum alloys. Adding elements like copper, magnesium, or silicon to aluminum can increase its strength but will decrease its conductivity. Therefore, while there isn't a 'better' type of aluminum in terms of conductivity, there are alloys with varying levels of conductivity based on their composition and purity.</p>

- Q: This question asks for the primary applications or purposes of using aluminum strips.

- <p>Aluminum strips are primarily used in various industries due to their lightweight, corrosion resistance, and high strength-to-weight ratio. They are commonly used in construction for framing and cladding, in the automotive industry for vehicle bodies and parts, in aerospace for aircraft components, and in electrical applications for wiring and conductors. Additionally, aluminum strips are employed in packaging, such as food and beverage cans, and in the manufacturing of electronic devices and heat exchangers. Their versatility makes them a popular choice for many applications where durability and performance are required.</p>

- Q: Is it possible to use aluminum strips as a covering for window or door frames?

- <p>Yes, you can use aluminum strips to cover window or door frames. Aluminum is a durable and lightweight material that can provide a sleek finish to your frames. It is resistant to corrosion and weathering, making it suitable for both indoor and outdoor applications. Aluminum strips can be easily cut and shaped to fit the contours of your frames, and they can be painted or anodized to match your desired aesthetic. However, ensure proper installation to maintain structural integrity and weatherproofing.</p>

- Q: Describe the steps involved in the manufacturing process of aluminum strips.

- <p>The process for manufacturing aluminum strips involves several key steps. Initially, aluminum ingots are melted in a furnace, often using a direct current furnace for better control over the melting process. The molten aluminum is then poured into molds to create a cast billet. This billet is then heated and passed through a series of rolling mills to reduce its thickness and achieve the desired strip dimensions. During rolling, the aluminum is continuously cooled to control its temperature and maintain its mechanical properties. After rolling, the aluminum strip may undergo additional processes such as annealing to improve ductility or coating to provide a protective layer. Finally, the strip is cut to length, inspected for quality, and packaged for distribution.</p>

Send your message to us

Strips of Aluminum for Industrial Cable & Wire - Aluminium Foil Strips

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 kg

- Supply Capability:

- 5000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords