Geogrids Fort Mcmurray Steel-Plastic Composite Geogrid for Coal Mine

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 88 m²

- Supply Capability:

- 1800000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction of CNBM

China National Building Materials (Group) Corporation (CNBM) is a state-owned enterprise in charge of administrative affairs in China building materials industry. Established in 1984, CNBM is a large group corporation of building materials with total assets of RMB 25 billion and a total staff of 30,000. Now CNBM owns more than 200 subsidiaries in and abroad the country, including wholly-owned corporations and joint ventures.

FAQ of geosynthetics :

What is geosynthetics ?

Geosynthetics form a perfect erosion control fabric used extremely widely in civil engineering to stabilize and reinforce slopes and soil under or next to roads, railways, dams, water reservoirs etc.. They can be easily applied which minimizes the time of construction, as well as they limit the resources and materials necessary.

What kinds of geosynthetics we have ?

Non-woven geotextile, geogrids, geocells, GCL, Geomembranes, Geonets, Geocomposites etc .

What is the geosynthetics used for ?

Hydraulic

Lagooning and Water Treatment, Ornamental Ponds, Golf Courses

Aquaculture and Desalination,Water Lagoons,Tanks, Reservoirs, Liquid Waste,Floating Cover Solutions, Drainage and Filtration

Environment

Tailing ponds, Leach mining,Landfills,Landfill Capping,Protection against corrosion,Vertical Barriers

Civil Works

Erosion Control,Secondary Containment,Tunnels,Linear and Surface Works,Consolidation of Margins,Soil Reinforcement,Soil Separation.

Building - Parkings,Roofing,Soundproofing

Structure of Steel-Plastic composite Geogrid for coal mine description :

Made of polypropylene and steel wire by extension technology after inflaming retarding and anti static treatment , it can bear high tensile strength .This material has considerable tensile strength in longitudinal and lateral directions. This chain structure can effectively bear and diffuse forces on soil and is applicable to large area permanent load bearing foundation as a reinforce.

Features of Steel-Plastic composite Geogrid for coal mine:

Homogenous structure, low creepage ,anti-aging and resisting acid and alkaline.

Inflaming retarding , anti static ,long lifetime,high safety factor ,high bearing capacity

Application of of Steel-Plastic composite Geogrid for coal mine :

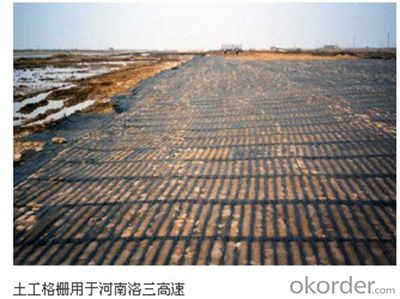

Make reinforce treatment for various of soft soil foundation to evenly distribute load stress and reduce unevensettlement , it is easy to wash coal . used in highway ,railway,port,airport, municipacl and projects of supporting in the recovery working face of coal mined and ladeway in the coal mine .

Specification of Steel-Plastic composite Geogrid for coal mine

Single mesh belt pulling strength not less than 4000N

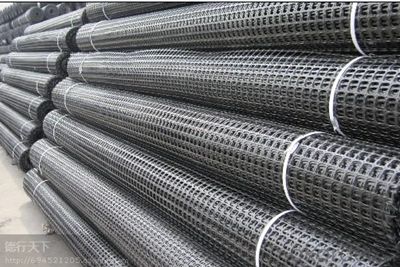

Width : 1M,2M,3M,4M.

Length: 50m,100,

Color: black

Packaging & Delivery of Steel-Plastic composite Geogrid for coal mine Each roll is wrapped in a woven bag then into container Or Packed as customers' requests.

Production periods of Steel-Plastic composite Geogrid for coal mine : within 10 days after receiving the deposit

- Q: Can geogrids be used in reinforcement of concrete structures?

- Yes, geogrids can be used in the reinforcement of concrete structures. Geogrids are high-strength synthetic materials that are commonly used to enhance the stability and strength of various civil engineering projects, including concrete structures. They are typically embedded within the concrete to provide additional tensile strength and prevent cracking or failure. Geogrids are particularly effective in applications where there is a need for increased load-bearing capacity, such as road and bridge construction.

- Q: How do geogrids improve the performance of mechanically stabilized slopes?

- Geogrids improve the performance of mechanically stabilized slopes by providing reinforcement and stability to the soil. They distribute the stress and load more evenly, reducing the potential for slope failure or movement. Additionally, geogrids increase the overall strength and integrity of the slope, allowing for steeper slopes to be constructed.

- Q: How much is the geogrid return

- This is based on the specific size of the size of the size of the geogrid length and width of the mesh size to determine

- Q: How to connect the geogrid with the panel in the reinforced earth retaining wall?

- When the geogrid is laid in the curve and the corner, the adjacent earthwork grid is currently used in the reinforced earth retaining wall of the assembled panel, and the common wall of the assembled panel module will have gaps or overlaps (see Figure 1). For the outward bending of the geogrid, there are different forms such as rectangle, hexagon, shape, L shape and groove shape. Panel module will appear at the corner of the gap,In order to ensure the continuity of the reinforced soil, laying in the void design based on the engineering environment need to be flexible, prefabricated into various shapes, can provide the same type of geogrid small pieces of good, and cover all the reinforced area; for bend shop visual effect; can also use color cement, add art wall. No panel reinforcement design of geogrid, in the corner there will be some overlap in geogrid, geogrid reinforced earth retaining wall is also called anti package type or wrap-reinforcedearth retaining wall, the wall is made of mesh bags to fill the overlap coefficient of friction will be reduced, must be laying a layer of 10mm ~ 20mm thick the soil geogrid anti package into each layer of geogrid is a special connecting rod is connected with the shape of the coarse sand layer, separate the two layer of Geogrid to ensure friction resistance. As a whole, the mesh bag filling has been mixed for local growth of grass and shrub seeds, seeds, after months of growth after the formation of green ecological wall. The utility model not only protects the safety of the geogrid, but also beautifies the environment of the retaining wall project.

- Q: Can geogrids be used in temporary construction access roads?

- Yes, geogrids can be used in temporary construction access roads. Geogrids are designed to provide reinforcement and stabilization to the ground, making them suitable for temporary access roads that may be subjected to heavy construction equipment and frequent traffic. They help distribute the load and prevent the road from rutting or becoming unstable.

- Q: Are geogrids resistant to extreme temperatures?

- Yes, geogrids are generally resistant to extreme temperatures. They are designed to withstand hot and cold weather conditions without significant degradation, making them suitable for a wide range of environmental applications.

- Q: Can geogrids be used in ground stabilization for oil and gas facilities?

- Yes, geogrids can be used in ground stabilization for oil and gas facilities. Geogrids are commonly used to reinforce and stabilize soil in various applications, including the construction of oil and gas facilities. They provide additional strength to the ground, preventing soil erosion, improving load-bearing capacity, and enhancing overall stability.

- Q: Can geogrids be used in railway track bed stabilization?

- Yes, geogrids can be used in railway track bed stabilization. Geogrids are commonly used in geotechnical engineering applications to improve the stability and performance of soil structures. In railway track bed stabilization, geogrids can provide reinforcement and increase the load-bearing capacity of the track bed, reducing settlement and improving overall stability.

- Q: What is the recommended installation method for geogrids?

- The recommended installation method for geogrids is to ensure proper preparation of the subgrade, followed by unrolling the geogrid on top and securing it with stakes or pins. It is important to overlap the geogrid panels correctly and avoid any wrinkles or folds. Finally, cover the geogrid with the desired fill material and compact it properly to maximize the effectiveness of the geogrid.

- Q: What criteria should be used in the construction of Geogrid

- A brief introduction of geogrid:A grille is made of polypropylene, PVC polymer and thermoplastic or molded by two-dimensional grid or a certain height of the three-dimensional mesh screen, when used as a civil engineering, called geogrid. Geogrid is a kind of main geosynthetics, which has unique properties and effects compared with other geosynthetics. Geogrid is often used as reinforcement of reinforced soil structure or composite material. Geogrid is divided into four categories: plastic geogrid, steel plastic geogrid, fiberglass geogrid and polyester warp knitted polyester geogrid.

Send your message to us

Geogrids Fort Mcmurray Steel-Plastic Composite Geogrid for Coal Mine

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 88 m²

- Supply Capability:

- 1800000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords