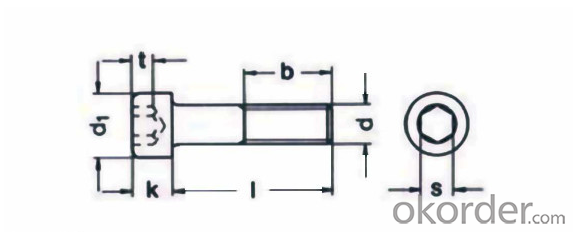

STAINLESS STEEL SOCKET HEAD CAP SCREW DIN912

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 100000000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1,the description of our main products :

The series of standard parts, stainless steel machine screws, self-tapping screws, outside hexagon screws, hex socket screws, set screws, nuts, Taiwan teeth, plain washers, spring washers, hole with elastic ring, shaft with elastic ring, open ring, gasket, different designs American-made inside and outside hexagon, top wire, nuts, mini screw; 12.9 Taiwan imported alloy steel of high strength screw; Allen wrench, ring spanner.

Non-standard processing: according to drawings, standards, sample processing.

GB, JIS, , DIN, ANSI/ASME,BS, ISO.

2,the application of the stainless steel screws

Electronics, medical equipment, hardware, mechanical, Marine, chemical industry, communications, construction, etc.

3,products show

3,stainless steel socket head cap screws

4,FAQ

Q: WHAT ARE YOUR ADVANTAGES?

A: 1. We have a specialized team in dealing with all the documents required by customers. We aim to zero error to save money and time for client. 2. We have a strict quality control from production to delivery. 3. We take use of advanced system and tool to improve working efficiency and control every step. 4. Professional sales team to serve customers. 5. Samples can be provided as your requirements. 6. Professional packing team which keep every packing safely.

Q: WHAT ARE YOUR MAIN PRODUCT?

A: We are specializing in providing cold rolled 201/410/430 Stainless Steel Coil / Stainless Steel Strip / Stainless Steel Sheet / Stainless Steel Plate, Stainless Steel Circle, Stainless Steel tube / Stainless Steel Pipe Sheets.

Q: CAN I GET FREE SAMPLE?

A: YES. We can provide free sample. However, you should be responsible for the transportation freight. Please tell us your express account or please send us the transportation freight of samples firstly, then we can arrange sample delivery.

Q: HOW MUCH THE TRANSPORTATION FREIGHT WILL BE FOR THE SAMPLES?

A: The freight depends on the weight and packing size and your area.

- Q: The idiom of the screw

- Lei Feng: I would like to always make a screw, a person's role, for the cause of the revolution, as a machine on a screw machine as a result of the many screws and fixed, only to become a solid whole, can Run freely, play its great ability to work. Although the screw is small, its role is not underestimated. I would like to make a screw hello forever. Screw to regular maintenance and cleaning, it will not rust. People's thinking is the case, to always check will not go wrong

- Q: Screw hole slip wire how to do?

- With a small amount of 502 glue into the screw hole, and then screw into the screw, such as glue after solidification and then use the tip of the nose to pull the screw out (only the screwdriver is not afraid of causing the screw teeth), waiting for the glue to fully hardened

- Q: What tools are used to remove the screws, the two lines are grooves, the middle of a paragraph is convex

- As for the professional name is not clear, probably should be called forked screwdriver it

- Q: What is a screw? What is a nail? What is the concept? What is the difference!

- Screws, screws luódīng, luósīdīng [Screw] Small cylindrical or conical metal rods with threaded parts, with a slotted or with a concave head, the use of machine nails alone? What machine nail Oh? How have I ever heard of it?

- Q: Screw M is mechanical teeth, tapping is what?

- Screw M is the size of the screw, can not use the nominal judge whether the screw is a mechanical screw or self-tapping screws. Metric tapping screws are marked directly above the name Tapping Type.

- Q: Also known as screw nails, I want to nail on the board, but there is no way to nail into the hard, how nail?

- 1, first clear the broken screw on the surface of the sludge with the center of the center of the gun will be killed by the center of the drill and then drill with a diameter of 6-8 mm drill bit in the center of the drill hole drilling, pay attention to the hole must drill through. After the hole is drilled, remove the small drill bit and replace the drill with a diameter of 16 mm. Continue to expand the hole of the bolt and drill it through. 2, take the diameter of 3.2 mm below the use of small and medium current in the broken bolt in the drilling from the inside to the outside of the surfacing welding site to take the beginning of the bolt half of the length of the bolt can not start too long So as to avoid breaking the outer wall of the broken bolt. Surfacing to the upper end of the broken bolt and then continue to pile out a diameter of 14-16 mm high 8-10 mm cylinder. 3, after welding with a hand hammer hammer its end point so that the broken bolt along its axial vibration.As the previous arc heat and subsequent cooling coupled with the vibration at this time will break the bolt and the body of the thread Between the resulting loosening. 4, carefully observed when you find a trace of rust after the break from the fracture when you can take the M18 nuts in the surfacing stigma and the two welding. 5, after welding with a cool hot plum wrench on the nut around the back and forth twist can also be back and forth twist side with a small hammer hammer the end of the nut so that you can remove the bolt off. 6, remove the broken bolt with the appropriate tap to the fabric within the rack to remove the hole to remove the rust and debris.

- Q: No cross screwdriver, how can the screwdriver screwdriver?

- Is the big nail? This is a lot of ways to find alternatives: glasses, calculators and other flat on the plane can be used to decorate the tip of the blade, be careful not to cut the hand do not cut the mirror material.

- Q: I would like to look at my mp4 apart, the above screws are small, is cross-type, our family is not so small screwdriver, what can be used to screw the screw Oh, a little practical method Kazakhstan,

- Is there a special small screwdriver that is special, if it is not used to cause or nails sometimes.

- Q: Inside the hexagonal screws, rather not down, it may be too much screw on the screw too tight has been bad 3 screwdriver screw is too small also one-half of rice grain please help think about ways

- First engage in a rust or diesel under the bubble. Then T-type wrench twist. (Own do)

- Q: How is the screw produced

- Should be used machine tools (lathe) processing and then re-processing of it only have it

Send your message to us

STAINLESS STEEL SOCKET HEAD CAP SCREW DIN912

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 100000000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords