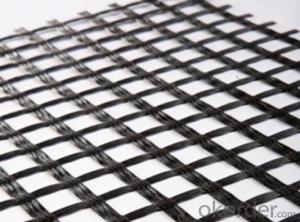

Geogrids from Thailand Supplier for Roadbed Reinforcement in Civil Engineering Construction

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 10000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction

Type:

Geogrids

Place of Origin:

Shandong, China (Mainland)

Brand Name:

OEM or Road

Model Number:

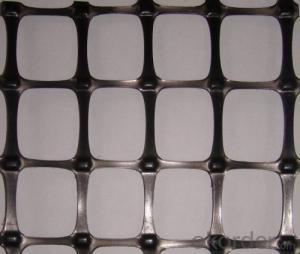

EGA50-50, EGA80-80, EGA100-100

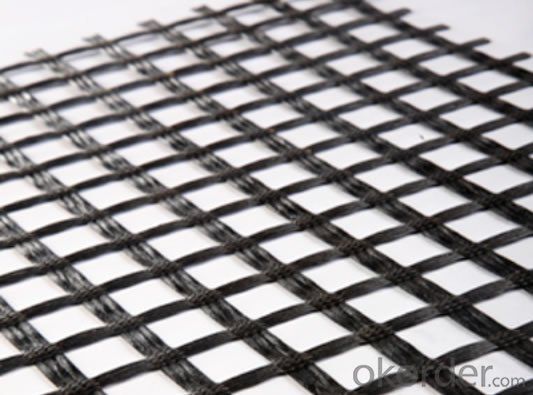

Some lighter strength polyester geogrids such as Stratagrid 150 are biaxial. These flexible grids are perfect for retaining walls less than 6' tall and are ideal for the novice retaining wall builder or homeowner.

Grass Protection Geogrids

We offer a unique line of extruded polymer grids for protecting and reinforcing grassed vehicular areas. Reinforcement Mesh is a tough extruded polymer grid for reinforcing grassed areas used by vehicles and pedestrians. Grass Protection Mesh is a heavy-duty extruded polymer grid designed to protect and reinforce grassed areas subject to vehicle traffic. Track Mat is an extra heavy duty thermoplastic extruded mesh manufactured from high density polyethylene (HDPE) designed to support large weights.

Our Service

Quality assurance

1.On a regular basis or as per your request,we entrust national testing agencies to conduct quality inspections

2. Strictly in accordance with the ISO9001-2008 international quality system standard,we monitor and manage the whole process throughout production,quality testing,and measurement to ensure product quality

3. For quality-related construction delay or substandard construction(except for damage or losses due to customer’s responsibility or irresistible natural disasters),we have refunding,replacement,and repair services.We will respond to customers’ feedbacks on quality issues within 24 hours.

Packaging & Shipping

Packing: PLASTIC FILM INSIDE, AND WOVEN BAG OUTSIDE

Shipping: About 15 days after receipt the deposit

FAQ:

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

Q: Do you have other products?

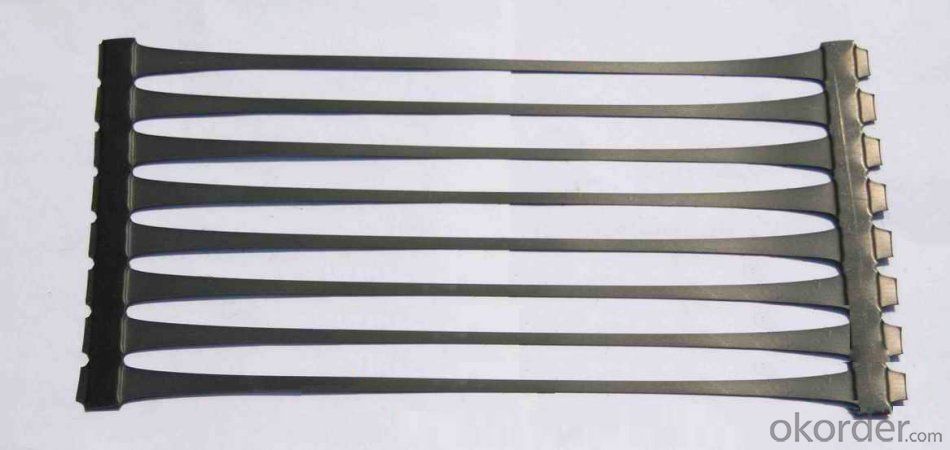

A: Yes, please check the pictures:

- Q: Can geogrids be used in reinforcement of rock slopes?

- Yes, geogrids can be used in the reinforcement of rock slopes. Geogrids are commonly used to stabilize and strengthen slopes by improving the stability and increasing the bearing capacity of the soil or rock. They are effective in preventing slope failures and erosion, and can be installed in combination with other methods such as rock bolts or shotcrete to provide additional support and reinforcement to the rock slope.

- Q: What are the factors to consider when designing with geogrids for reinforced soil walls?

- When designing with geogrids for reinforced soil walls, there are several key factors that need to be considered. These factors include the type and properties of the soil, the anticipated loads and stability requirements, the slope angle and height of the wall, the installation and construction process, and the long-term durability and maintenance of the geogrids. Additionally, factors such as environmental conditions, drainage requirements, and aesthetic considerations may also play a role in the design process. By carefully considering these factors, engineers can ensure that the geogrids are properly designed and implemented to provide effective reinforcement and stability for the soil wall.

- Q: Are geogrids resistant to microbial attack?

- Yes, geogrids are typically resistant to microbial attack.

- Q: Are geogrids resistant to high temperatures?

- Yes, geogrids are typically resistant to high temperatures. They are designed to withstand extreme weather conditions, including high temperatures, without significant degradation or loss of performance.

- Q: Do geogrids provide reinforcement to geosynthetic clay liners?

- Yes, geogrids can provide reinforcement to geosynthetic clay liners. Geogrids are typically used in combination with geosynthetic clay liners to improve their tensile strength and overall performance. The geogrids help distribute loads and restrain the movement of the clay liners, enhancing their stability and reinforcement capabilities.

- Q: EG65R type geogrid meaningWhat is the meaning of EG, said 65 per meter of tensile strength is 65kN? 65KN/m R will be broken? What is the meaning?

- Is that tension can reach more than 65KN, as can pull off in what, I do not know, if there is a need to contact me, thank you, hope to adopt!

- Q: Can geogrids be used in retaining wall facing systems?

- Yes, geogrids can be used in retaining wall facing systems. Geogrids are commonly used to reinforce and stabilize soil in retaining walls, and they can help enhance the overall strength and stability of the wall. They are typically placed within the soil layers behind the facing system to distribute the forces and prevent excessive movement or failure of the retaining wall.

- Q: How do geogrids help stabilize soil?

- Geogrids help stabilize soil by providing reinforcement and increasing the overall strength of the soil. They are typically made of high-strength materials such as polyester or polypropylene, and are placed within the soil to distribute loads and limit movement. This prevents soil erosion, improves slope stability, and enhances the bearing capacity of the soil, thus effectively stabilizing it.

- Q: How to fill in the geogrid evaluation form

- Detection method and frequency in accordance with the requirements, the other reference to your command requirements!

- Q: Can geogrids be used in retaining wall construction?

- Yes, geogrids can be used in retaining wall construction. Geogrids are commonly used as a reinforcement material in retaining walls to improve their stability and strength. They are designed to provide additional support and prevent the soil from sliding or eroding.

Send your message to us

Geogrids from Thailand Supplier for Roadbed Reinforcement in Civil Engineering Construction

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 10000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords