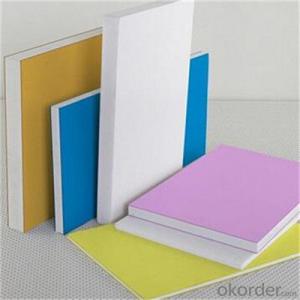

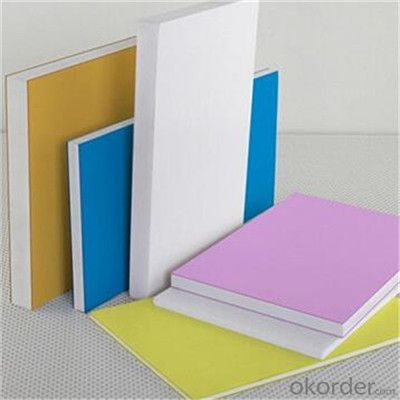

PVC Foam Sheets board for Furniture Wall Almirah Designs

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Instruction

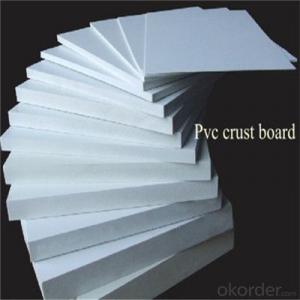

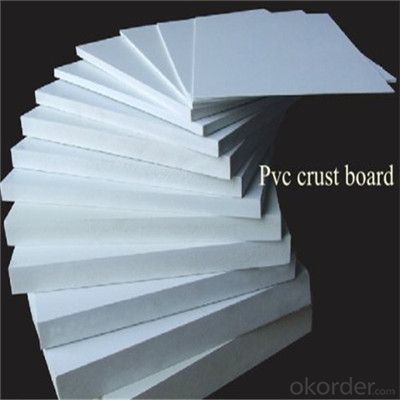

PVC Foam Board//PVC Celuka Board//PVC Foam Sheet//Solid PVC Board has same processing methods as wood, such as cutting,sawing, digging, opening holes, nailing, screwing, adhering, and also has the processing methods with thermal bonding and plastic welding which is more superior than wood.

PVC Foam Sheet Specification

Regular size: 1220*2440mm, 1560*3050mm, 2050*3050mm

Thickness:1-33mm

Density:0.43mm-0.9mm

Features

1)light weight, 100%rigid surface,waterproof,fire retardant and self-extinguishing

2)Sound insulation,heat insulation,noise absorption,heat preservation and anti-corrosion, anti-chemical.

3)Tough,rigid with a high impact strength,not easy to age and can keep its color for long

4)Easy to clean and maintain.

Applications for PVC Board

1. Building outdoor wall board, indoor decoration board, partition board in office and house.

2. Screen printing, flat solvent printing, engraving, billboard and exhibition display.

3. Chemical anti corrosion project, special cold project, environmental protection.

4. Sanitarywares, kitchen cabinet, washroom cabinet.

Picture

- Q: Hi guys, I'm about to tile my bathtub surround and have some questions regarding moisture barriers. I already have the 1/2 durock cement board and 6 mil plastic sheeting. Before I put up the plastic sheeting on the studs, I wanted to double check to see what people thought was a better moisture barrier... Redgard painted directly onto the cement board or the 6 mil heavy duty plastic sheeting attached to the studs. If you pick one over the other, can you tell me why? Is there a difference in how well each one will protect from long term moisture problems? It would be nice to hear the pros/cons to Redgard vs the plastic sheeting.I'm debating whether or not I should just go buy some Redgard and leave my plastic sheeting for another purpose. But if they both offer the same long term protection, then I'm happy just sticking with my plastic sheeting since it will save me a trip to the store and I am more familiar with that as a moisture barrier.

- The problem with using a paint-on barrier like Redgard is that if you miss a spot or if there are any breaks in the application, you have an entry point for moisture. Plastic sheeting on the other hand, is continuous and will seal uniformly unless there's a breach in it such as a cut or puncture. I would think the plastic sheeting would be easier to apply. That would be my choice.

- Q: Are plastic sheets transparent or translucent?

- Plastic sheets can be either transparent or translucent, depending on their composition and thickness.

- Q: I have an idea for something I would like to make and sell. I would like to be able to stamp or cut a fairly simple shape out of flexible plastic sheets, a bit like margarine tub plastic. What machine/device/tool would I need to be able to cut or stamp this shape (and yes, I know scissors would work, but I would like to be able to make quite a few)

- A die cutter is one method. You can see simple versions at craft stores, it is like a cookie cutter with a sharpened edge. However, these cost a bit to have custom made, and they get dull. A CNC milling machine or Laser cutter could cut these out. A computer controlled engraving machine with the right bit could do this, too. The drawback is that it isn't incredibly fast, but you can change the shape at any time. CNC stands for Computer Numerical Control, what that means is that, like a Laser cutter you draw it on the computer. Then it uses a small spinning bit to cut out the plastic. Engraving machines are purpose-built CNC milling machines.

- Q: Is PVC plastic board afraid of sunlight?

- PVC ceiling boards are afraid of the UV part of the sunlight, which makes the plastic aging and brittle.If you need to be exposed to the sun, use the sun board... It has an anti UV coating to prevent plastic aging.

- Q: We have a dog kennel. The inteiior walls have sheet metal glued to them so the dogs could not chew through the dry wall.I would like to cover the sheet metal with frp but don't know if it will work since frp panels are made to be used on drywall. Anyone have knowledge in this area?

- You should be able to apply the FRP with nylon rivets. I would not try to just glue the panels as the glue may or may not stick to the metal long term.

- Q: We used our Graco Pack and Play for our daughter and now we are expecting another baby and I am again trying to figure out how exactly were supposed to cover the top piece when we change our little one?

- No but they have waterproof pads that have holes for the straps.

- Q: How long do plastic sheets typically last?

- The lifespan of plastic sheets can vary depending on various factors such as the type of plastic used, the quality of the sheet, and the conditions in which it is used. However, on average, plastic sheets can last anywhere from a few years to several decades.

- Q: are pvc plastic sheets and acetate sheets made from the same or similar things?

- they are different. acetate can be transparent like glass and isn't very flexible. I haven't seen clear PVC (thats not to say it doesn't exist) but it can be very flexible- like garbage bags or it can be made hard - like plastic pipes. PVC is more a group of plastics

- Q: What do you put underneath sand so that it doesnt touch the ground. It is like a sheet.?

- Best advice is to use clear plastic poly sheeting. This is widely available in all kinds of sizes and thicknesses. I would recommend at least a 6 mil thickness. This sheeting is cheap and is available at Lowe's and Home Depot. They will have it available in clear and black in a number of sizes and thicknesses. One thing to keep in mind is that water will not drain through the plastic. For example, if you are lining a children's play sandbox with plastic sheeting, it will hold water and take forever to dry out. Good luck with your project.

- Q: How can I remove the glass glue from the plastic?

- Acetone. Method ibid. Less and thoroughly, and best of all, it removes the residual gum quickly, easily, and more efficiently than the essence. All two of these are solvents and are the best in all methods.

Send your message to us

PVC Foam Sheets board for Furniture Wall Almirah Designs

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords