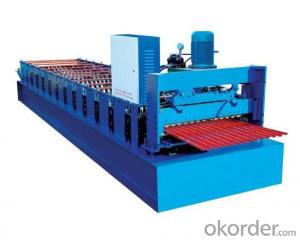

pressure tile machine840/900

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Parameters of 840/900 type double pressure tile machine:

Size: 5700mm x 1500mm x 1500mm

Molding method: roll forming (pre press forming)

The number of rows: V900 roll forming 10 rows of pre press forming, V840 roll 11 rows of pre press forming

The feed width: 1000mm

Rolled plate thickness: "0.6mm

Equipment shaft diameter: diameter 70mm

Host power: 3KW

The rolling speed: 10m-12m/min

Machine weight: About 3000kg

Pump motor: 3KW

Equipment: 300H steel frame

Cutter material: Cr12 (CR 12)

Equipment: sprocket, chain drive

The equipment frame all adopt 250# I-beam welding

Plate thickness: 14mm

Full automatic computer fixed length cutting system

840/900 type double pressure tile machine and its components include: machine, PLC computer control system, hydraulic pump station system, automatic cutting system after the equipment characteristics: the color steel plate equipment using automatic control software of high level, the realization of the production information management. The whole unit automation control system using high integrated network, make automation system performance is more superior. The double pressure tile machine also has the advantages of operation, maintenance, maintenance as well as mechanical test, mould easy replacement, etc..

Debugging method of double-layer pressure tile machine type 840/900:

First put pressure tile machine before and after the four horns and two queue from big frame exactly measure the height of the upper end of the shaft is consistent, and then from the first row to the last row, find a straightened wire, check, whether under shaft in a straight line, the lower shaft left and right sides move into level.

Then the pressure tile machine first and last row find good center on both sides, then tighten lock nut, pull a straight line in the center of the middle wheel is before and after the clearance adjusting the upper and lower shaft well, can adjust machine down the line.

Debugging method finally pressure tile machine platen deviation, such as plate rightwards run, pad left corner (feed frame), or drop the right flat bottom (the first of several axis deviation does several shaft on the shaft with the flat bottom, the bottom shaft falling).

- Q: What are the shortcomings of traditional machining?

- First, the production efficiency is low, the cost, followed by the processing quality is not stable, the third labor intensity, lack of security.

- Q: Information on building materials decoration.

- Equipment Construction Projects Cooperation Adhesives Metal Building Materials Insulation Materials Building Materials Door and Window Wall Materials Wood Sheet Other Building Materials Products Construction Materials Stone Stone Lime, Gypsum Plastic Building Materials Locks Ceramic Processing Machinery

- Q: Information on building materials decoration.

- products special building materials ceiling paint culture stone processing machinery brick, tile and block decoration building materials agent operating reference:

- Q: Classification and components of hydraulic press

- according to the size of the equipment according to the size of equipment, hydraulic equipment can be divided into large equipment, medium-sized equipment, small equipment.

- Q: Mechanical processing technology to mechanical product design, specifically to prepare what?

- To do the theoretical basis of mechanical design is essential, learn a few auxiliary tools, CAD, PRO / E, slidworks are more commonly used.

- Q: Main classification of hydraulic machinery?

- (4) According to the importance of equipment in the production system or application classification, hydraulic equipment can be divided into key equipment, key equipment and general equipment.

- Q: What gear is machined out of the gear?

- The bevel gears are laid on the planer. Spiral bevel gears - forming end mills.

- Q: What is the principle of the cutting order in machining?

- In the arrangement of mechanical cutting process, should be based on the processing stage of the division, the choice of benchmarks and the surface to be processed to decide, generally should follow the following principles:

- Q: What are the aspects of the mechanical processing quality

- The so-called machining precision refers to the actual geometric parameters (size, shape and surface of the mutual position between the workpiece) and the ideal geometric parameters of the degree of compliance. The higher the degree of compliance, the higher the machining accuracy.

- Q: What are the oyster processing companies?

- printed posters printing desk calendar printing calendars printing business cards printing envelopes printing paper printing stickers printing other commercial printing processing books printing processing paper processing 2 processing laser plus .. The

Send your message to us

pressure tile machine840/900

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches