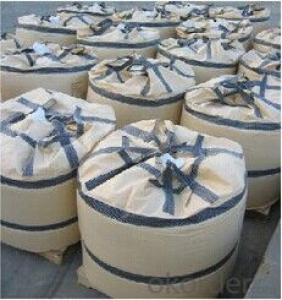

PP PE woven Big bag for chemicals

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

PP Bag & HDPE Bag, big bag, jumbo bag, FIBC bag, container bag,

Features:

- heat cut top, top with drawstring, topwith valve, hemmed top etcare available

- Printing: 3 color printing available

- Materials:100% PP/PE

- Water proof

- lamination fabric prevents damage fromrain moisture HDPE or LDPE inner linger protects contents from bad weather

- twisted yarn or special ink makes roughbag surface which gives antislip effect

- Printing: 3 color printing available

Place of Origin | China (Mainland) |

Model Number | 100X100X120cm |

Feature | Antistatic,Breathable |

Bottom Option (Discharge) | With Spout |

Loading Weight: | 2000kg

|

Loop Option (Lifting): | Cross Corner Loop |

Safety Factor: | 5:1 |

Top Option (Filling):

| Top Fill Spout

|

Packaging Detail: 10 bags/bale 20 bags/bale 100 bags/bundle or pallet, etc

- Q: How to control the quality of plastic packaging bottles?

- Use caliper or handle to detect whether the wall thickness of bottle is uniform.

- Q: What are the advantages and uses of container bags?

- The container has the advantages of reusable, recyclable, low weight, easy to machine, loading and unloading operation, and easy to transport logistics

- Q: What are the main liquid packaging of pesticides in China today?What is the Dragon bottle factory? Do you have a website?What kind of bottle is HDPE? Chinese name?The advantages and disadvantages of fluoride bottles and bottles of dragon "?PE/PET/HDPE/ high barrier, respectively, their respective advantages and disadvantages?Thank you for professional analysis!The Dragon bottle and bottle, which is better?How big is the price gap?

- PE, PET barrier performance is not good HDPE, general water products can test PET bottles, and solvent products have to choose HDPE bottles, and if still can not reach the standard weight loss, then we should consider the barrier bottle or fluoride bottle

- Q: What are the requirements for the manufacturing process and quality of the container manufacturers?

- Safety factor is the ratio between the maximum product capacity and the rated design load. Mainly see, several times the contents of the container bags, repeated lifting, content and bags are abnormal, the connection is damaged. In domestic and foreign similar standards, the safety factor is usually set up 5-6 times. Five times safety factor container bags can be used safely for longer. It is an indisputable fact that if the anti ultraviolet additive is increased, the application scope of container bags is wider and more competitive. When the sling is connected with the bag body, there are many kinds of forms, such as top hanging, bottom hanging, side hanging, etc., and the thread is also connected through the suture, so the suture is also very important.

- Q: Is TYPE A an anti-static container?

- Type A: commonly used container bags, of which U and cubic bags, cone bags and leak proof bags are the most expensive bags we produce.Type B: antistatic bag with an inner coating with a breakdown voltage of not more than 4 thousand volts. This container can be used in places where flammable dust is available, but not in hazardous areas.

- Q: Could you tell me how big the packing capacity of soft packages is? How much is the packing bag? Does the soft packing affect the flavor of the products? Ask for advice..

- Disadvantages: shelf life is significantly shorter than metal cans, easy to damage, direct lighting and Winton changes can damage the cans more greatly, the content is easy to break. The flavor is basically the same as that of other canned goods.

- Q: What are the uses of packaged bottles and pictures?.

- 3, extra large bottles, especially glass bottles, can be used to place long string necklaces without having to buy jewelry boxes. 4, some cosmetics counters engage in activities, and empty bottles can be recycled for small samples. 5, and that with straw, olive oil or their own deployment of compound essential oils installed, drop out at any time, wipe hands

- Q: Packaging tank process flow diagram?

- High frequency resistance stitchwelding Park, barrel bending local annealing, bending, flanging, edge sealing cover.

- Q: Packaging bottles, that is, all kinds of glass bottles of foreign trade, good?

- As for how to develop the business, these have to work hard, anyway, inquiry every day. This is a test of patience industry, sometimes feel tired!

- Q: What are the logistics packaging technology and methods?

- Small bags (or ordinary packing bags): these bags are packed in less weight and are usually made of single or double layers. For some special packing bags, many layers of different materials are also used. Packaging a wide range of liquid, powder, block and shaped, etc., can use this package.

Send your message to us

PP PE woven Big bag for chemicals

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords