Polyester Insect Pleated Screen Mesh in Large MOQ

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20000 m²

- Supply Capability:

- 5000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Polyester Insect Pleated Screen Mesh in Large MOQ

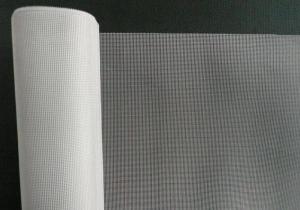

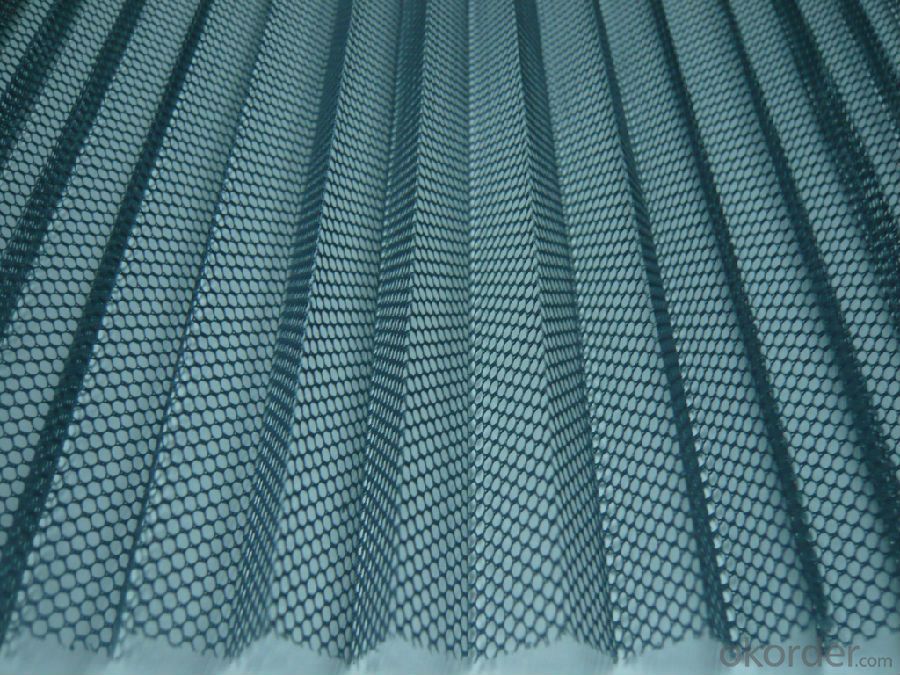

Description of Pleated Insect Screen mesh

Black Pleated Insect Screen mesh is a kind of pleated mesh with economical and practical. It made by polyester yarn, best suitable for the pleated/plisse screen window and door system. It is widely used for air exchange and insects proof in high-grade office building, residence and various buildings. It is also used for field, garden, vegetable shed, ect.

Advantage of Pleated Insect Screen mesh

▪ Best protective product to keep out a wide range of pests and insects

▪ Anti-UV, Anti-Static, Water proof, Durable

▪ Easy to clean, and easy to operation.

Specification of Pleated Insect Screen mesh

PRODUCT | Pleated Insect Screen mesh | |

WOVEN STRUCTURE | PLEATED | |

COLOR | GRAY, BLACK, | |

YARN DIAMETER (MM) | WARP | 0.3±0.02MM |

WEFT | 0.3±0.02MM | |

ENDS DENSITY (ENDS/INCH) | WARP | 18 |

WEFT | 16 | |

AREA WEIGHT (G/M2) | 75±5G/M2 | |

COMPOSITION | POLYESTER | |

BREAKING STRENGTH (N/25MM) | WARP | >180 |

WEFT | >160 | |

STANDARD WIDTH(M) | FROM 0.6M TO 2.7M | |

STANDARD PIECE LENGTH(M) | 30M | |

PIECES LENGTH (PC) | AVAILABLE UPON REQUEST | |

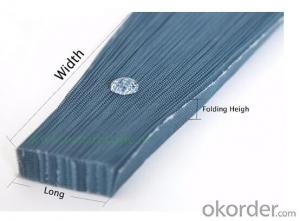

Images of pleated insect screen

Package of Black Pleated Insect Screen mesh

FAQ:

1. What's the quality?

Very fine, we have been exported to more than 30 countries.

2. How long get reply?

Usually within 24 hours.

3. What's the MOQ?

2000 square meters.

- Q: What are the specifications of the ground copper braid for 500mm2 cables

- 35 square armored cable grounding metal braid with 16mm^2. Code for construction and acceptance of cable installation of electrical installations in accordance with national standard GB50168-2006

- Q: Today at the Tianjin TV station Home Furnishing turned inside, with a rope made up of a spider web type wall storage I want to know is how the spider web series, how to map the rope? What kind of?

- Take a look at spider man

- Q: I made a handicraft with copper wire, "Liuhe tower", can apply for a patent?

- But I don't know if there's anything else

- Q: How to make a window protective net with wire

- We used to do this with a steel wire

- Q: Method of weaving nets

- Two sets of yarns by twisting methods and machine twist twist, at the handover point with each other through the network into a network, called twist twist knotless net. Because the net yarn nodules without bending, the net is smooth, friction is reduced, but the twist twist machine of low efficiency, complicated preparation procedure, t-meshes Co., is only suitable for large woven mesh.

- Q: Want to know the braided copper wire sleeve heat shrinkable tube structure and its application

- Copper raw materials for the PVC plastic copper stranded wire, the installation of seamless copper contact surface,Stamping process does not use any similar to tin or other additives.

- Q: Weaving rules of spider webs

- For example: the first to circular knitting and weaving ring

- Q: The aluminum foil shielding layer can be designed into a smooth, concave and convex structure, which is used to replace the composite shielding of the aluminum foil + metal braid

- No, the role of metal woven mesh is to spread out the static electricity

- Q: Can you make a mesh with a wire rope? Can you make a mesh with a wire rope?

- However, to determine the size of the mesh size, the size of the network size

- Q: In the purchase of hot and cold sink, toilet, water heater hose, is the choice of stainless steel braided hose, or stainless steel corrugated pipe

- Stainless steel braided hose household, mostly stainless steel braided hoseStainless steel corrugated pipe is used on the site, thank you for the best

Send your message to us

Polyester Insect Pleated Screen Mesh in Large MOQ

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20000 m²

- Supply Capability:

- 5000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords