PET Laminated Aluminum Foil for Bitumen Membrane Production

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 66000 m²

- Supply Capability:

- 10000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Introduction

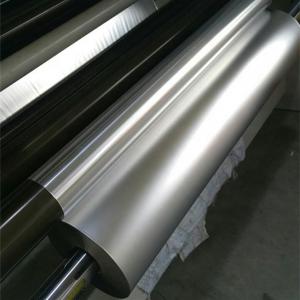

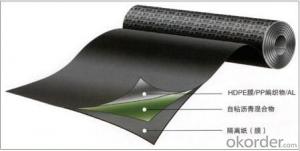

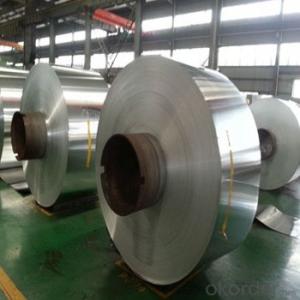

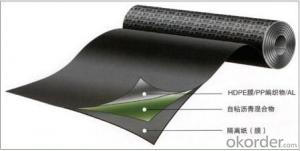

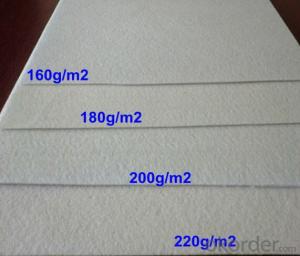

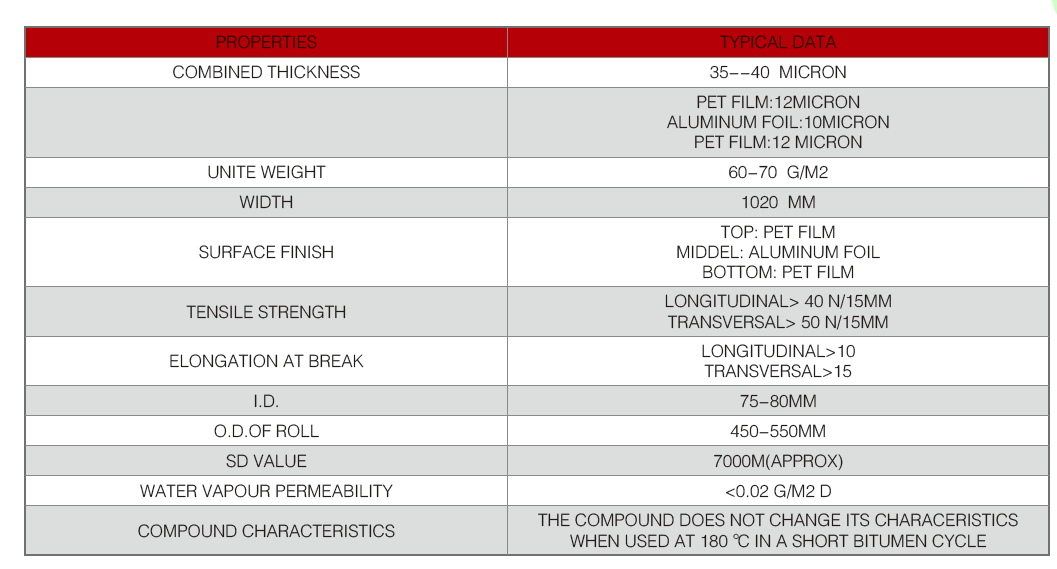

PET laminated aluminum foil is an improved surfacing material for SBS/APP modified bitumen waterproofing membrane. It has all the aluminum foil functions. Since it is the lamination of PET film and aluminum foil, it is more fl exible and with higher strength.

PET composite aluminum reinforcement film is made of metal alumina film composited with polyethylene terephthalate (PET) film. The film is uniform and very smooth and clean without wrinkles, tears, granules, bubbles, and pinholes or other defects. The film has excellent mechanical properties, heat resistance, and very low cost.

Usage

●Surface film for self-adhesive waterproof membranes and other waterproof materials.

● For cables production, packaging materials

● Release liner for cast materials, electronic applications, ceramic capacitors, window materials, printing, and advertisements

Application

● Keep temperature

● Damp-proofi ng

● Improve membrane's fl exibility and service life

Features:

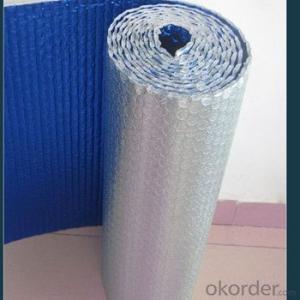

1. Light weight, clean, thin and good flexibility;

2. Invariable if it is attacked repeatedly;

3. Low thermal conductivity and superior heat insulation, reflective 97%;

4. Outstanding safety and environmentally friendly;

5. Easy to install, high efficiency.

It can also laminated with LDPE with specifications as below,

| Manufacturing Technics | Structure | Size |

| Extrusion coating | Al(7mic)+LDPE(13mic)+LLDPE Film(25mic) | 1100mm*1000m |

| Al(9mic)+LDPE Film(25mic) | 1500mm*2000m | |

| Al(7mic)+PET(12mic)+LDPE(25mic) | 1500mm*2000m | |

| Dry-lamination | Al(9mic)+LDPE Film(30mic) | 1100mm*2000m |

| Al(7mic)+LDPE film(25mic) | 1250mm*2000m | |

| Al(7mic)+PET(12mic) | 1250mm*200m | |

| LDPE(50mic)+Al(12mic)+LDPE(50mic) | 1250mm*2000m |

- Q: Waterproof materials related to the raw materials which ah

- ③ cement waterproof material. Adhesives, such as water repellents, aerators and expansives, can enhance the hydrophobicity and impermeability of cement mortar and concrete. The cement and sodium silicate Mortar, can be used for underground engineering plugging waterproof.

Send your message to us

PET Laminated Aluminum Foil for Bitumen Membrane Production

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 66000 m²

- Supply Capability:

- 10000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords