Woven Geogrids - High Tensile Strength Pet Geogrid Customizable

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m²

- Supply Capability:

- 2000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

High tensile strength at low elongation

Low tendency to creep

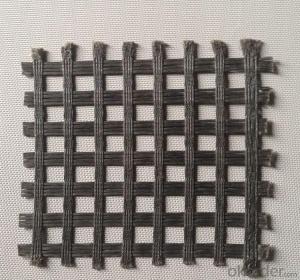

Optimized grid structure

PET Geogrid 30-1200kN/m

Bitumen / PVC

PET geogrid for road,slope,airport,retaining wall,breakwater,marine and soil reinforcement 30-1200kN/m

Basic Info:

Grid® geogrid is made of filament yarn with high strength, high modulus and low creep deformation through advanced coating technology. Grid is 3m—6m wide and 100m—300m long,and can reduce the connecting rate.

The tension force of Grid® geogrid ranges from 200KN/m—1200KN/m, and we can provide geogrid with tension force ranging from 800KN to 1200KN for special projects and partially reinforced geogrid,composite geogrid and other kinds of geogrid according to project requirements.

Geosynthetics have been an essential material for projects , like highway, railway, airport road, bridge, tunnel and culvert

Grid® geogrid has a better ecomomic efficiency and enviromental effect and it is simple, agile, safe and efficient to use.

Feature:

The warp knitting polyester geogrid has high intensity. The high module, the high module,the low slow change. The anti-aging,the anti-embrittlement,the tensile strength to be high strength,the anti-peel strength is big .

Application:

1.Reinforced soil engineering(reinforced soil retaining wall, steep slope and the reinforcement and consolidation of the soft ground);

2.Road construction(ground treatment, reinforcement of the bridge abutment, reinforcement of the enbankment, reinforcement of the pile-net roadbed)

3. Irrigation projects(protection of port, approach lane, seabeach, channel, river channel, dam and other irrigation projects.)

4. Enviromental projects(land reclamation, prevention and controlling of the desertification,and the composite protective structure in the landfill sites of urban garbage and waste)

5. Mine engineering(coal mines, side slope protection of opencast mines, slope protection for the dumping site of the opencast mines,reinforcement to counter dam in the large tailing ponds of the metallurgical mines)

6. Construction of stuffing and package system of heavy soil engineering

7. slope protection in the area affected by earthquake

8. Ground consolidation of large dump leaching sites and slag site.

Packing and Delivery

| Packaging Details: | PE film |

| Delivery Detail: | within 10 days after contract is effective |

Geogrid Show:

FAQ:

1. How to order your geogrid ?

a). Tensile strength in warp & weft direction

b). Grid size

c). Width and length

d). Quantity

2. Payment term .

a) TT

b) LC AT SIGHT

c) cash

d) 30% contact value as deposit ,the blance 70% be paid after received the copy of bl .

3. Delivery time

a) 19-25 days after received your depsit .

4. What is MQQ ?

a) 2500 m2 as MQQ , we can also produce sample for you .

- Q: Are geogrids suitable for reinforcing railway ballasts?

- Yes, geogrids are suitable for reinforcing railway ballasts. Geogrids provide effective soil reinforcement and stabilization, enhancing the load-bearing capacity and overall performance of railway ballasts. They help distribute loads more evenly, reduce settlement and deformation, and improve the long-term stability of the ballast layer. Geogrids also help prevent lateral spreading of the ballast material, maintaining track alignment and reducing maintenance requirements. Overall, geogrids are a reliable and effective solution for reinforcing railway ballasts.

- Q: The ground treatment is full of geogrid is not along the line direction

- Because the geogrid is rolled

- Q: Are geogrids suitable for use in high water table areas?

- Yes, geogrids are suitable for use in high water table areas. Geogrids are commonly used in construction and civil engineering projects to provide soil stabilization and reinforcement. They are designed to withstand high water table conditions, making them an effective solution in such areas. Geogrids can help distribute loads, increase soil strength, and prevent soil erosion, making them a reliable choice for projects in high water table areas.

- Q: What are the benefits of using geogrids in pavement construction?

- Geogrids offer several benefits in pavement construction, including improved stability and load-bearing capacity, reduced cracking and rutting, increased pavement lifespan, and cost savings. By reinforcing the soil or aggregate base, geogrids distribute the load more evenly, preventing the formation of potholes and reducing maintenance requirements. Additionally, they enhance the overall structural integrity of the pavement, making it more resistant to heavy traffic and environmental factors such as freeze-thaw cycles. Ultimately, utilizing geogrids in pavement construction leads to longer-lasting, more durable roads with reduced maintenance needs, resulting in cost savings over time.

- Q: Can geogrids be used in reinforcement of underground utility corridors?

- Yes, geogrids can be effectively used in the reinforcement of underground utility corridors. Geogrids provide structural support and stability to the soil surrounding the utility corridors, minimizing the risk of settlement and shifting. They improve the load-bearing capacity of the soil, preventing damage and potential collapse of the underground utility infrastructure. Additionally, geogrids can help distribute loads more evenly and reduce stress concentration, ensuring the long-term durability and performance of the utility corridors.

- Q: What is the difference between geogrids and geotextiles?

- Geogrids are typically used for soil reinforcement and stabilization, providing structural support to prevent soil movement. On the other hand, geotextiles are used for filtration, drainage, and separation purposes, allowing water to pass through while preventing soil migration. Essentially, geogrids focus on reinforcement, while geotextiles focus on filtration and separation.

- Q: Can geogrids be used in streambank stabilization applications?

- Yes, geogrids can be used in streambank stabilization applications. Geogrids are commonly used in these applications to reinforce and stabilize the soil, preventing erosion and providing structural support to the streambank.

- Q: What is the minimum net size of geogrid mesh Center

- This depends on the material

- Q: Do you need a geogrid to fill the stone roadbed?

- Please figure forAre generally required to do

- Q: Can geogrids be used in erosion control applications on steep slopes?

- Yes, geogrids can be used in erosion control applications on steep slopes. Geogrids are often employed in such situations to stabilize the soil and prevent erosion by providing reinforcement and increasing the overall strength of the slope.

Send your message to us

Woven Geogrids - High Tensile Strength Pet Geogrid Customizable

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m²

- Supply Capability:

- 2000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords