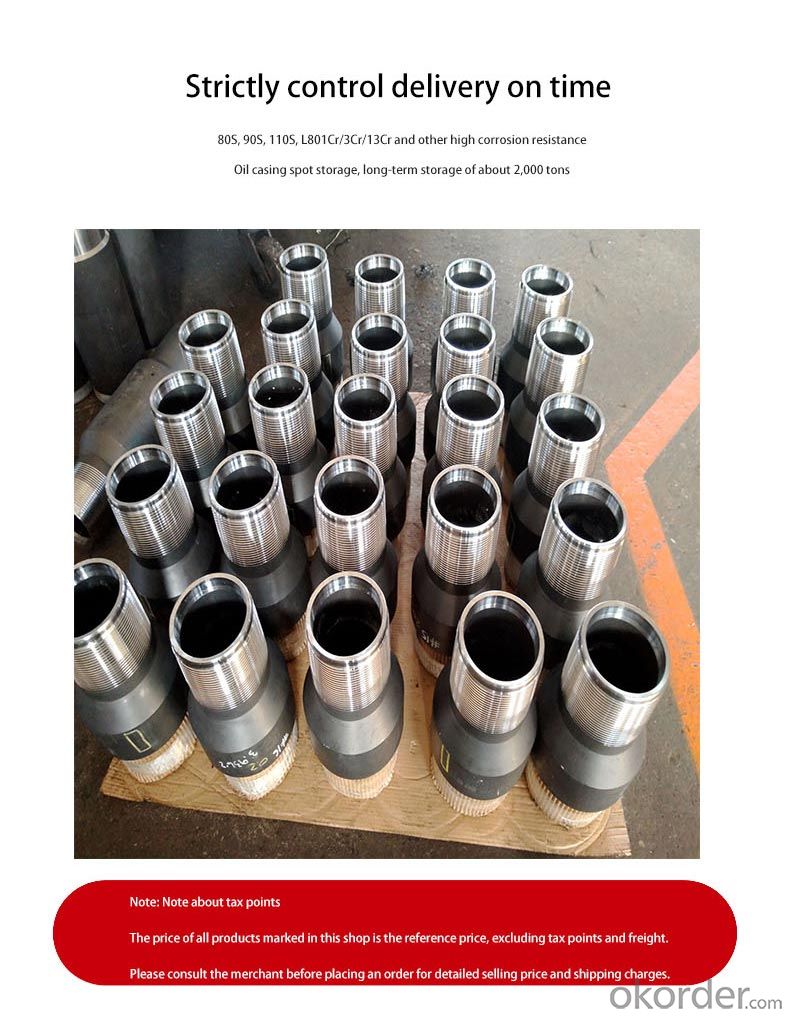

Oil Casing and Tubing Size Charts, Specifications, Steel Grades, and Connection Materials

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 1300 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product | J55 L80 13cr oil casing pipe in steel pipes | |

Outside Diameter: | Wall Thickness: | |

Size | 6-1240mm | 1-200mm |

Tolerance | +/-1% | +/-6% |

Length | 1.00-12.00M or according to the client’s requirement | |

Brand Name | GUANGXIN | |

Material | J55 L80 13cr oil casing pipe in steel pipes | |

Q195,Q215,Q235B,Q345,20#,45# and so on | ||

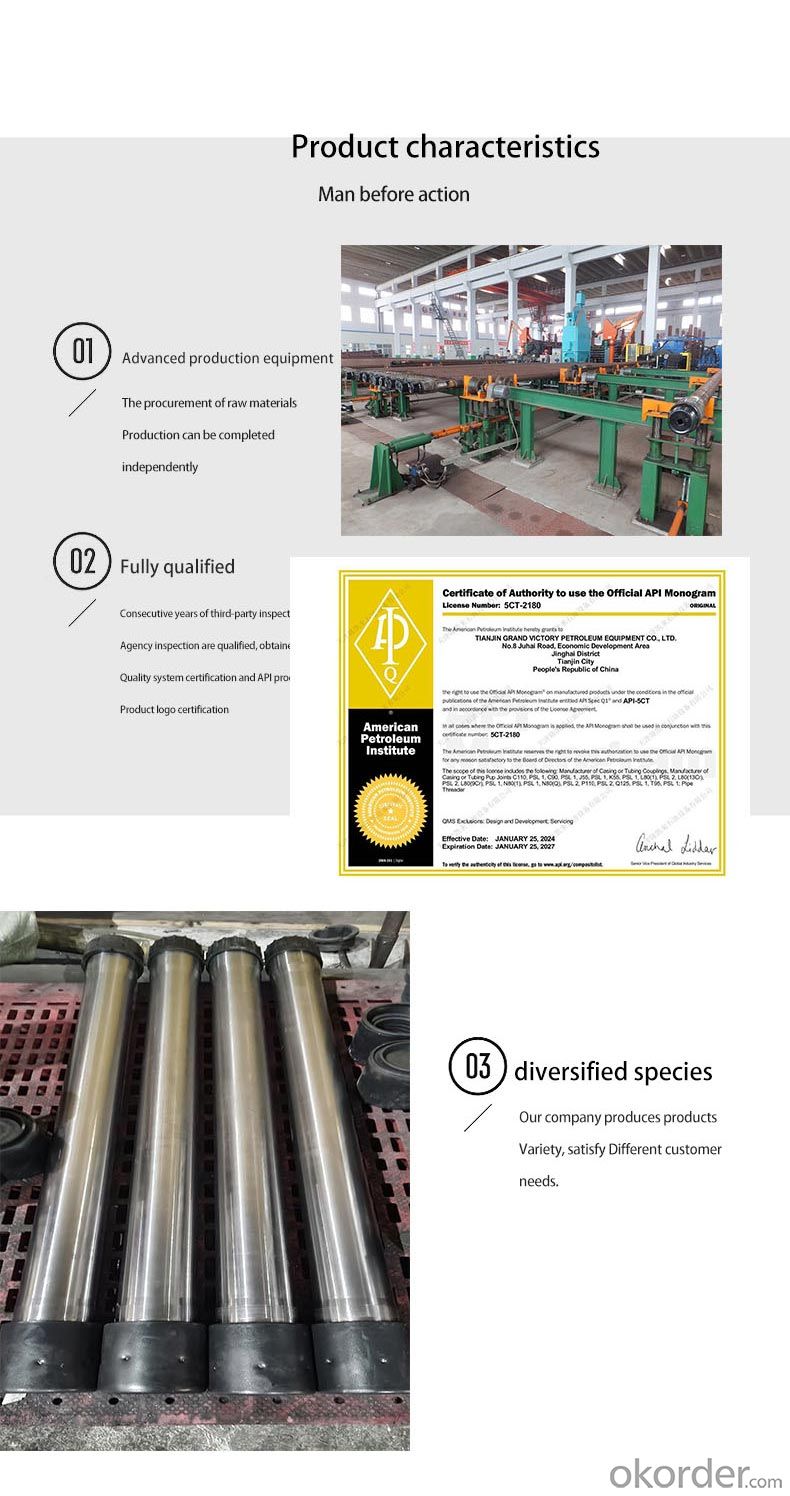

Standard | ASTM/ BS/ GB/DIN and so on | |

Surface | oiled or painted | |

Usage | For low pressure liquid delivery such as water and gas. | |

For construction. | ||

For structure | ||

Payment | T/T or L/C | |

Trade Term | FOB/CNF/CIF | |

Delivery Time | Within 15 days | |

Package | 1.Large OD: in bulk | |

2,Small OD: Packed by steel strips, in bundle | ||

3,As per to clients | ||

- Q: How are steel pipes graded?

- The quality and suitability of steel pipes are determined by grading them based on several factors. The grading system typically takes into account parameters such as the chemical composition, mechanical properties, manufacturing method, and testing standards. 1. When it comes to the chemical composition, steel pipes are graded according to the elements present in their composition. This includes the quantities of carbon, manganese, phosphorus, sulfur, and other alloying elements. The pipe's strength, corrosion resistance, and other properties are greatly influenced by its chemical composition. 2. The mechanical properties of steel pipes play a crucial role in determining their strength, flexibility, and resistance to pressure and temperature. These properties encompass tensile strength, yield strength, elongation, hardness, and impact toughness. Pipes with higher mechanical properties are generally given higher grades. 3. The manufacturing method used for steel pipes can vary, with options such as seamless, welded, or ERW (Electric Resistance Welding). The manufacturing method has an impact on the pipe's integrity, dimensional accuracy, and overall quality. For example, seamless pipes are considered to be of higher quality due to their uniformity and lack of weld seams. 4. Steel pipes are graded based on their adherence to specific testing standards. These standards ensure that the pipes meet the required quality criteria and are suitable for their intended applications. Common testing standards include ASTM (American Society for Testing and Materials), API (American Petroleum Institute), and EN (European Norms). Taking these factors into consideration, steel pipes are often assigned alphanumeric codes or specifications for grading. For instance, pipes used in the oil and gas industry may be graded as API 5L (American Petroleum Institute), while pipes used for structural purposes may be graded as ASTM A500 (American Society for Testing and Materials). In conclusion, the grading of steel pipes is determined by their chemical composition, mechanical properties, manufacturing method, and adherence to testing standards. These grades assist customers and manufacturers in selecting the appropriate pipes for specific applications, ensuring safety, durability, and efficiency across various industries.

- Q: Can steel pipes be used for steam applications?

- Yes, steel pipes can be used for steam applications. Steel pipes are known for their high strength and durability, making them suitable for carrying steam at high temperatures and pressures. They are resistant to corrosion and can withstand the harsh conditions of steam systems, making them a popular choice in various industries such as power generation, oil and gas, and chemical processing.

- Q: What's the difference between a cracked carbon steel tube and a liquid carbon steel tube?

- Cracking carbon steel pipe higher requirements, the general carbon steel pipe to be normalized, the fluid carbon steel pipe as long as the normal annealing treatment.

- Q: What does "1.5" steel tube mean?

- 1.5 inch [1 1/2 steel pipe, outer diameter 48.3mm, 1.5 inches, refers to the pipe bore is approximately the inner diameter (25.4x1.5 = 38.1mm). [DN40] the specific parameters of the steel pipe are as follows;The average wall thickness is: 3.5mm;The minimum wall thickness is 3.06mm,Nominal diameter is 40mm,External Jing is 48.3mm,

- Q: Are steel pipes resistant to UV radiation?

- Yes, steel pipes are generally resistant to UV radiation. UV radiation is known to cause damage to materials over time, such as fading, discoloration, and degradation. However, steel pipes are typically coated with protective layers, such as paint or galvanization, which help to shield them from UV radiation. These coatings act as a barrier, preventing the direct exposure of steel to UV rays and minimizing the potential for damage. Additionally, the inherent properties of steel, including its strength and durability, make it less susceptible to the effects of UV radiation compared to other materials like plastics or rubber. However, it is important to note that prolonged exposure to intense UV radiation can still have some impact on steel pipes, such as slight discoloration or surface degradation. Regular maintenance and inspection are recommended to ensure the continued performance and longevity of steel pipes in outdoor or UV-exposed environments.

- Q: Can steel pipes be used for irrigation systems?

- Yes, steel pipes can be used for irrigation systems. They are commonly used due to their durability, strength, and resistance to corrosion. Steel pipes can handle high water pressure and are suitable for both above-ground and underground installations in irrigation systems.

- Q: How are steel pipes used in firefighting systems?

- Steel pipes are commonly used in firefighting systems as they provide durability and resistance to heat, making them ideal for transporting water or fire extinguishing agents. These pipes are used to create a network of water supply lines, sprinkler systems, and hydrants that are crucial for effectively extinguishing fires and controlling their spread.

- Q: How are steel pipes used in railway infrastructure?

- Steel pipes are used in railway infrastructure for various purposes such as constructing bridges, tunnels, and track supports. They are also used for drainage systems, signaling and telecommunication cables, and as conduits for electrical wiring.

- Q: How do steel pipes handle water hammer in high-rise buildings?

- Steel pipes in high-rise buildings are designed to handle water hammer by incorporating various features. Firstly, these pipes are often equipped with pressure relief valves or surge tanks that absorb and dissipate the sudden pressure changes caused by water hammer. Additionally, engineers use techniques such as proper pipe sizing, installation of air chambers, and use of flexible connectors to minimize the effects of water hammer. These measures help to reduce the sudden pressure spikes and prevent damage to the pipes and other plumbing components in high-rise buildings.

- Q: What are the different types of steel pipe coatings for corrosive environments?

- There are several types of steel pipe coatings specifically designed for corrosive environments. Some common options include fusion-bonded epoxy (FBE) coatings, liquid epoxy coatings, polyethylene (PE) coatings, and polyurethane (PU) coatings. These coatings provide a protective layer to prevent corrosion and extend the lifespan of the steel pipes in various corrosive conditions.

Send your message to us

Oil Casing and Tubing Size Charts, Specifications, Steel Grades, and Connection Materials

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 1300 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Related keywords