China Mineral Fiber Ceiling Tile, 12mm/15mm Mineral Fiber Board Ceiling 60x60cm

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3000 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1,Structure of (Mineral Fiber Ceiling) Description

Mineral fiber acoustic ceiling is a high-grade interior decorative material. It has undergone the process of burdening, forming, drying, cutting, surface finishing and spray coating after being added with additive. As the high-grade interior decoration material for suspended ceilings, the product is applied to elegant interior design of high-class buildings such as hotels, restaurants, gymnasiums, office buildings, shopping malls, studios, computer rooms, airports, station, factories, hospitals and home decoration.

2,Main Features of the (Mineral Fiber Ceiling)

Color: White, Black

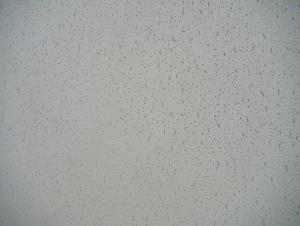

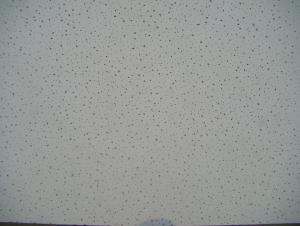

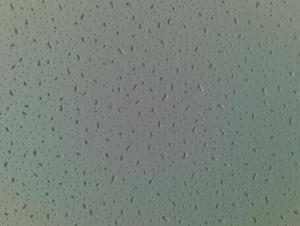

Pattern available: Astro series, fissured seriers, pinhole seriers, sand seriers, etc.

Density: 240-280 kgs/m3

Noise reduction coefficient (NRC):0.55

Light Reflectivity: 0.85

Fire Resistance: non-combustible, Class A as per ASTM E 84

Humidity Resistance (RH): 90%

Recycled Content: 63%

3,(Mineral Fiber Ceiling) Images

4,(Mineral Fiber Ceiling) Specification

Loading

Metric system | British system | Thickness | Packing | QUANTITY M2 / 40HQ |

Actual size(mm): 595x595/595x1195

Nominal size(mm): 600x600/600x1200 | Actual size(mm): 603x603/603x1213 605x605/605x1213 618x618/618x1243

Nominal size(mm): 610x610/610x1220 625x625/625x1250 | 12mm | 12PCS/CTN | 5520m2 |

13mm | 12PCS/CTN | 5010m2 | ||

14mm | 10PCS/CTN | 4600m2 | ||

15mm | 10PCS/CTN | 4400m2 | ||

18mm | 10PCS/CTN | 3500m2 |

5,FAQ of (Mineral Fiber Ceiling)

Remark:

Ceiling tiles could be loaded with T grids together in one container.

1.Sound absorption and noise reduction

2.Damp-proof, Anti-sagging

3.Fire-resistant

4.Safe and environment friendly

5.Elegant and fashionable

Light Reflectivity: 0.85

Fire Resistance: non-combustible, Class A as per ASTM E 84

Humidity Resistance (RH): 90%

Recycled Content: 63%

- Q: I would like to know what is the door of the decorative panels open when the sound of the resonance when the ring can do to solve

- Inside the plug cotton

- Q: I have a problem. In my utility closet the ceiling fell down. I never knew because I never had a reason to go into my utility closet.it s been like this for probably 2 years...Only maintainence would go in a d they never said anything..Now that I m seeing this hole into our attic. The insulation looks disgusting. What ever it is looks very hard and dusty I think it use to be blown in insulation. But all of the soft stuff is on the ground . What s on the ceiling looks grown on. It s attached to absolutely nothing it s just stretched.

- If your house is newer than 1980, there is virtually no chance of it being asbestos. Get into the 70s and older and there starts to be some doubt. It could also be mineral wool. Mineral wool installs and behaves like fiberglass, except it's made from, if I recall correctly, foundry slag that has been blown into fibers a bit like cotton candy. Fiberglass insulation is generally pink or murky yellow, but mineral wool is usually gray. Use the same precautions with it as you'd use for fiberglass and you should be fine. Blown in insulation is usually cellulose. A mask should be all you need with it. If you are in any doubt, call a pro. Getting the material tested so you can be sure won't set you back too much, and it's a hell of a lot cheaper than needing to talk to a pulmonary specialist.

- Q: i have a loft style condo with 27ft ceilings, and i am tired of getting noise complaints. i am trying to absorb bass as well as peoples voices. what style acoustic foam do you recommend? pyramid or wedge?

- here are some suggestions. you can put high density insulation in the walls or that shredded blue jean stuff if you have the ability to do that. there is also a product called soundboard that comes in a 4x8x1/2 sheet that goes behind the drywall. i am going to assume you are not a nuisance tenant like having parties and band practice and whatnot. you and your neighbors decided on a condo which means sharing a wall with other people if they cannot tolerate you talking or watching tv or baby crying, tell them to insulate their own walls or don't live in a condo, go buy a house. there isn't a whole lot they can do.

- Q: Fatal bug in integrated wall!

- If you unfortunately choose aluminum alloy wall as a decorative wall, then the electric shock will be inevitable. As the decoration power supply is now a lot of excuses, Insulation is normal, but if exposed to aluminum, it will cause fatal problems! Electric shock dead is normal.

- Q: Do you think the new UV decorative board market?

- Pattern clarity and brightness is the industry's best, in general, the quality is more secure.

- Q: Great Wall c30a column decorative board buckle how to install, with a few buckle?

- Hello, first put the seat belt side of the screw apart, 6 buckle around

- Q: PVC hollow concavo buckle decorative plate recipe?

- The surface is decorated with wood grain, but also the use of PVC special ink or UV curing ink, printed directly on the buckle plate. The process is: Ingredients → High-speed mixing → Extrusion granulation → Extrusion molding → Cooling tank shaping → Tractor traction → Sawing to a certain length (4m) → Gravure transfer printing → Coating UV light assimilating agent → PVC shrink film packaging PVC decorative concave convex deduction plate factory.

- Q: TV wall with UV decorative board good? What are the advantages?

- The benefits of using the angle: a. Easy installation, labor, time, material. When the angle of the tile or stone without corner, chamfer, will be tiled and stone master only three nails can be completed installation. B. Decoration beautiful, bright. Corner arc smooth, straight lines, can effectively ensure that the package edge paste straight, so that the corner of the decoration more three-dimensional beauty. C. Rich colors, can be the same color with, so brick, edge line consistency, can also be different colors with the formation of contrast. D. Can be very good to protect the tile corner. E. Product environmental performance is good, the use of various raw materials on the human body and the environment without adverse effects. F. Safe, rounded at right angles to reduce the harm caused by the collision.

- Q: There is no ready-made wall decoration board

- Jin Kima metal insulation decorative board is a kind of high pressure, earthquake, moisture, water, fire, noise, insulation, low thermal conductivity, beautiful, durable, energy saving, simple construction, environmental protection and so on a series of excellent performance of the new Building materials, can be widely used in schools, hospitals, hotels, stations, villas, the old building appearance transformation, mobile board room, post booth, kiosks, power facilities, light steel structure, plant and so on.

- Q: Color stainless steel bronze, green bronze, red bronze metal decorative plate where the company to do better, the best color to be deeper,

- Now color stainless steel bronze, green bronze, red bronze and other colors can be transferred out through the processing,

Send your message to us

China Mineral Fiber Ceiling Tile, 12mm/15mm Mineral Fiber Board Ceiling 60x60cm

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3000 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords