Microporous Insulation Board Classification Temperature:1000-1100C

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 2000 pc

- Supply Capability:

- 30000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Description of Microporous Insulation Board:

CMDS Microporous Insulation Board is specially designed for steel industry & metallurgy with very good thermal and mechanical properties. The formulation is an opacified blend of filament reinforced pyrogenic silica. The coverings is water repellent to assure the stability of the microporous board when moisture may occur due to castables, mortar etc.

2.Main features of Microporous Insulation Board:

◆ Extremely low thermal conductivity ◆High compressive strength

◆ High thermal stability ◆Environment protection

◆ Easy to handle ◆No harmful inhalable fibers

◆ Resist most chemical attacks ◆Free of organic binders

◆ Non combustible

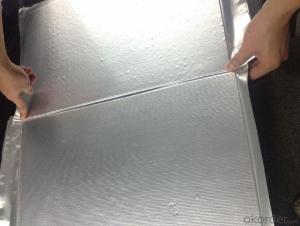

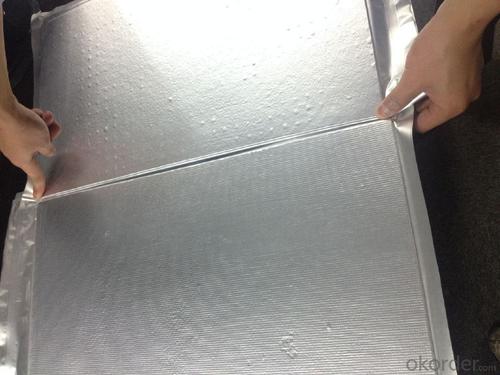

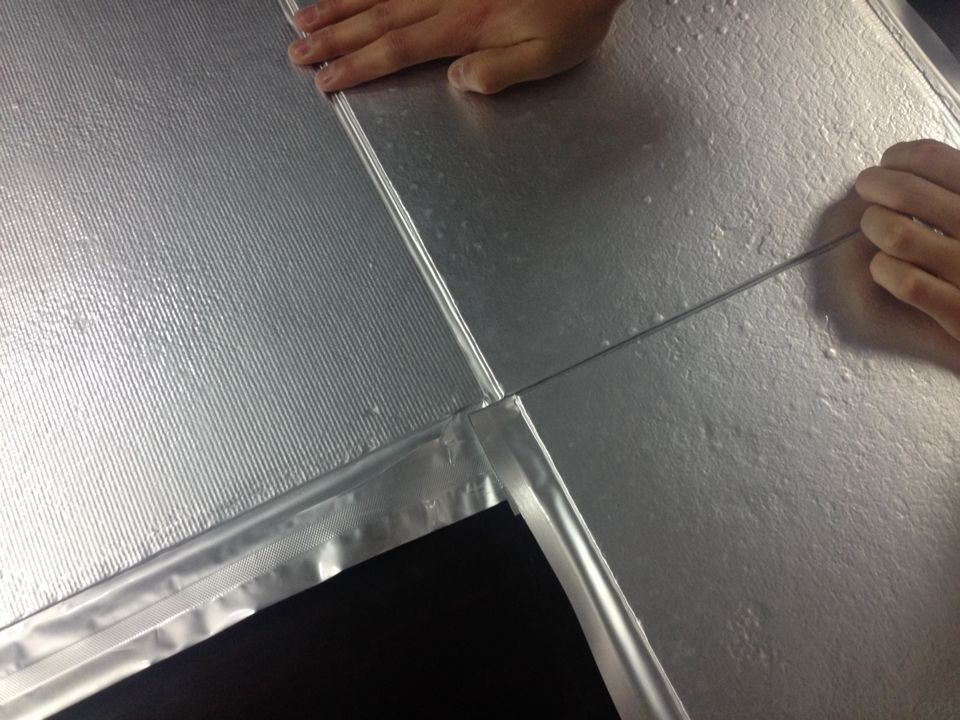

3. Microporous Insulation Board Images:

4. Microporous Insulation Board Technical Parameters

CMDS Microporous Insulation Board can be shaped easily with a simple cutter and taped off with aluminum tape. The board can be fixed in place with the same adhensives that are used for refractory lining.

Application: Ladle, Torpedo Ladle, EAF, Degassers, Cement Rotary Kiln, Ceramic Firing Klin, Aluminum Melting and Holding Furnace and so on. If you need other application picture, please contact with us

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

① How about your company?

A world class manufacturer & supplier of Microporous Insulation Board is one of the large scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirement.

②How to guarantee the quality of the products?

We have established the international advanced quality management system every link from raw material to final product we have strict quality test; We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q: How to do waterproof bathroom, construction process is what

- 2, brush the second time waterproof coating. It should be noted that the first coating to be dry before the second brushing, the specific time depending on the product characteristics may be. If the interval is too short, the first pass of the paint has not been dry, waterproof effect will be greatly reduced.

- Q: What is the car waterproof sticker material?

- Engraving process car sticks A. knife engraving process: refers to the computer will be vector graphics input knife machine, the knife will be cut into a preset film shape, and then by hand will be different colors together Finished, and finally in the finished product posted on the surface of a layer of transparent transfer film, after the stickers to remove the stickers; due to knife car paste production process is complex, high cost of materials, currently only suitable for individual car and Che Youhui team Small customization

- Q: Can acrylic materials be perforated? How to do waterproof after punching?

- Acrylic material thickness is generally below 2MM, Plus the total thickness of glass fiber reinforced plastic materials are generally below 4MM,

- Q: How do you make waterproofing in the kitchen and bathroom?

- Kitchen and toilet is a relatively stable part of the home improvement structure, it is recommended to do waterproof mortar waterproofing agent on it, mortar waterproofing agent not only with the base surface bonding firm, and puncture resistance, high strength, waterproof life and construction Material with the life, the construction of relatively waterproof coating is also relatively simple.

- Q: What material waterproofing can be mixed with cement sand

- Construction can be made with the waterproofing agent and cement made of waterproof mortar. The ratio of cement to sand is 2: 3, and the amount of waterproofing agent is 1% of the cement.

- Q: Do you use the waterproof material on the building to be harmful to the human body?

- If you are out of the finished line, the best anti-static that can! I plant is the production of waterproof material, in addition to the internship when I went to the workshop, and now I do not go!

- Q: What is the car material so that the car can be waterproof, in the rain will not leak in?

- ?C. metal technology and other: metal technology refers to the aluminum plate and other metal plate through the machine to suppress the concavity and convex surface, and then made of metal paint color, and finally after grinding, drawing and other production of the car stickers (car standard); Area can not be too large, can only be used for a small range of iconic car stickers.

- Q: Why should the use of high pressure perfusion waterproof plugging method

- Due to uneven settlement of buildings and other factors, resulting in deformation of the building structure cracking, leakage phenomenon, for the repair of this situation, you can use a new foreign plugging construction technology - high pressure grouting waterproof repair technology.

- Q: What are the materials used in the ceiling?

- Kitchen bathroom ceiling material is divided into four categories, namely, PVC material, aluminum gusset material, waterproof gypsum board, sauna board. Kitchen bathroom ceiling material 1: PVC material ????PVC is made of vinyl chloride in the role of the initiator made of thermoplastic resin, made of honeycomb shape. Suitable for use in damp places such as kitchen and toilet, because the PVC material ceiling in the life of a certain guarantee, you can use for 50 years without damage, while waterproof, heat insulation effect is good, but also has a certain noise Effect, in the kitchen is the best use of the ceiling material.

- Q: Finished house bathroom waterproof household acceptance should be how to accept?

- Bathroom waterproof acceptance: material acceptance: 1: materials need to meet the national standards, the need for a product certificate of competency. Construction acceptance: 1: grass-roots surface should be flat, no hollowing, from the sand, cracking and other defects. Base water content should meet the construction requirements of waterproof materials.

Send your message to us

Microporous Insulation Board Classification Temperature:1000-1100C

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 2000 pc

- Supply Capability:

- 30000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords