High Temperature Masking Tape Gun Dispenser for Auto Painting - Packing Packaging

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 roll

- Supply Capability:

- 200000 roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Application of Masking Tape for High Temperature Auto Painting

Interior paint masking, silk screening, Light duty packaging, bundling, holding, splicing &Tabbing, and other non-critical applications where a pressure-sensitive tape is needed.

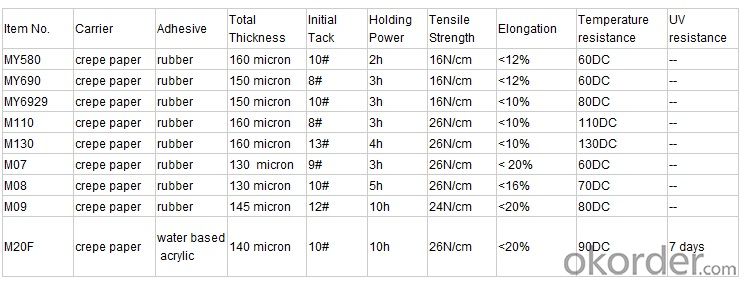

Technical Data of Masking Tape for High Temperature Auto Painting

Size of Masking Tape for High Temperature Auto Painting

Paper Core ID: 76mm

Jumbo size: 0.99m x 1800m, 1.22m x 1800m, 1.51m x 1800m

Cut roll size: As per customer's requirement

Cut rolls: Shrink package, placed in cartons, with or without pallet

Packing of Masking Tape for High Temperature Auto Painting

Jumbo rolls & log rolls: Packed with kraft paper and stretch wrap film, with or without pallet

Cut rolls: Shrink package, placed in cartons, with or without pallet

Jumbo rolls & log rolls: Packed with kraft paper and stretch wrap film, with or without pallet

Picture Show of Masking Tape for High Temperature Auto Painting

FAQ: What are your company advantages?

Company Advantages:

1. Stable financial status and sound reputation as a state invested corporation under the direct administration of the State Council of PRC;

2. CNBM’s world wide influence as one of the 500 global fortunes specializing in building materials including adhesive tapes;

3. More than a decade’s exporting experience and technology in adhesive tape industry;

4. Preferencial shipping channels, with a separate team dealing with shipping.

- Q: Does packaging tape come in different lengths?

- Yes, packaging tape does come in different lengths. It is available in various lengths to cater to different packaging needs and requirements.

- Q: Does packaging tape come in different thicknesses for added durability?

- Yes, packaging tape does come in different thicknesses for added durability. Thicker tapes are often preferred for heavier or more secure packaging needs, as they provide increased strength and resistance to tearing or breaking.

- Q: Can packaging tape be used for sealing plastic bags?

- Indeed, sealing plastic bags can be accomplished with the utilization of packaging tape. Designed with robust adhesive properties, packaging tape can effectively secure various items, including plastic bags. To achieve a secure seal and prevent spillage or exposure to air and moisture, the tape can be applied either along the opening or across the entire width of the bag. It is worth mentioning, though, that while packaging tape can serve the purpose, it may not be as efficient as specialized plastic bag sealing techniques like heat sealing or ziplock closures, which are specifically engineered for this particular task.

- Q: Can packaging tape be used for sealing poly mailers?

- Yes, packaging tape can be used for sealing poly mailers. Packaging tape is commonly used to seal a variety of packaging materials, including poly mailers. It provides a strong and secure seal that prevents the contents from falling out or being tampered with during transit. However, it is important to ensure that the tape is applied properly and securely to ensure the integrity of the seal. Additionally, it is recommended to use a high-quality packaging tape that is designed for secure sealing to ensure the best results.

- Q: How does packaging tape perform on fabric or textile surfaces?

- Packaging tape typically does not perform well on fabric or textile surfaces. While it may adhere temporarily, it does not provide a strong bond on these materials and is not designed to withstand the flexibility and movement of fabrics. Additionally, the adhesive on packaging tape may leave residue on the fabric or even damage it when removed. Therefore, it is not recommended to use packaging tape on fabric or textile surfaces. Instead, it is advisable to use specialized fabric tapes or sewing techniques for any applications involving fabrics.

- Q: Can packaging tape be used for sealing medical or pharmaceutical supplies?

- Sealing medical or pharmaceutical supplies with packaging tape is not recommended. These supplies require a higher level of sterility and protection from contamination, which packaging tape may not provide. Instead, specialized medical-grade packaging materials like medical adhesive tapes, tamper-evident seals, or sterile packaging are typically used. These materials are designed specifically for the healthcare industry's stringent requirements, ensuring the supplies' integrity and safety. Using packaging tape for sealing medical or pharmaceutical supplies can compromise their sterility and increase the risk of contamination, which could have serious consequences for patients' health. It is crucial to adhere to industry standards and guidelines for packaging and sealing these supplies to maintain their quality and safety.

- Q: What are the considerations for using packaging tape on plastic or polyethylene bags?

- There are several factors to consider when using packaging tape on plastic or polyethylene bags. To begin with, it is crucial to choose the appropriate type of packaging tape for these surfaces. Certain tapes may not adhere well to plastic or polyethylene, resulting in poor adhesion and easy peeling. It is advisable to opt for tapes specifically designed for these materials, as they are typically formulated with adhesive that adheres properly. Another factor to take into account is the tape's strength and durability. Plastic bags are often lightweight and flexible, so it is important to select a tape that can provide sufficient strength to secure the bag's contents. Look for tapes with a strong adhesive backing that are resistant to tearing or stretching. Consideration should also be given to temperature and environmental conditions. Extreme temperatures can impact the tape's adhesive properties, leading to decreased adhesion or brittleness. If the bags will be exposed to high or low temperatures, it is recommended to choose a tape specifically designed for those conditions. Furthermore, it is essential to ensure that the tape does not cause any damage to the plastic or polyethylene bags. Some tapes may have strong adhesives that leave residue or cause harm when removed. Look for tapes labeled as having low residue, easy removal, or being safe for use on these surfaces. Lastly, aesthetics and presentation should be considered. Packaging tape is available in various colors and designs, allowing you to choose a tape that complements the bag's appearance or branding. It is important to make sure that the tape does not obstruct any important information or barcodes on the bag. In conclusion, when using packaging tape on plastic or polyethylene bags, it is important to consider selecting the right tape, ensuring strength and durability, taking into account temperature and environmental conditions, preventing damage to the bags, and considering aesthetics and presentation.

- Q: What is the size of the transparent sealing tape? The length is 50 yards and 100 yards. Is that the meter?

- As for what you mean, 50 yards and 50 meters are not the same thing. The.1 code equals 0.9144 meters

- Q: Food packaging, sealing tape printing and product manufacturers inconsistent with the use of it?

- This generally does not affect how, but this is the image of manufacturers

- Q: Is packaging tape safe to use on painted surfaces?

- Packaging tape is generally safe to use on painted surfaces, but there are a few factors to consider. Firstly, it is important to ensure that the paint is fully cured before applying any tape. This typically takes around 30 days, depending on the type of paint used. Applying tape to fresh or uncured paint can cause damage when the tape is removed. Secondly, the type of tape used can also make a difference. Most packaging tapes are designed to be easily removable without leaving residue or causing damage to surfaces. However, some low-quality tapes or tapes with strong adhesives may leave behind sticky residue or even peel off the paint when removed. It is recommended to use high-quality packaging tape that is specifically labeled as safe for painted surfaces. To be on the safe side, it is always a good idea to test the tape on a small, inconspicuous area of the painted surface before applying it extensively. This will help you ensure that the tape does not cause any damage or leave residue behind. If there are any concerns, it is advisable to consult the manufacturer's instructions or seek professional advice. Overall, when used properly and on fully cured paint, packaging tape should be safe to use on painted surfaces. However, it is important to exercise caution and choose the right tape to prevent any potential damage.

Send your message to us

High Temperature Masking Tape Gun Dispenser for Auto Painting - Packing Packaging

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 roll

- Supply Capability:

- 200000 roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords