JS1000 concrete mixer

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

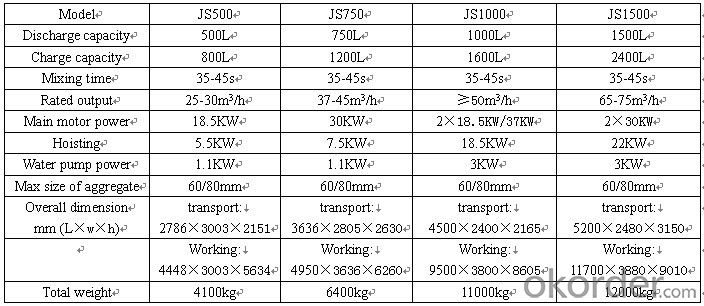

The model of the machine is JS series double-shaft compulsory mixer which have the advantages of reasonable structure, safe and reliable operation, low energy,excellent mixing performance, high efficiency and so on. It has the dual advantage of standalone using or as the supporting host of the concrete batching plant. This machine can composed with different kinds of PL series dosing machine of the concrete batching plant, or according to the customer requirements as the host of the large or medium-sized concrete batching plant, can mixing dry-hard, lightweight aggregate concrete and any other various kinds of mortar. It is suitable for all medium or large construction sites which is the ideal equipment of the hydropower, roads, ports, airports, bridge, medium or large concrete prefabrication plants and the manufacture of the commercial concrete. Now we have JS500, JS750, JS1000, JS1500, JS2000, JS3000 and any other type available.

- Q: What are the small concrete mixers

- The concrete mixer is divided into a falling mixer and a strong mixer The JZC series: JZC250.350.500 single-sleeper shaft machine mixer: JDC series: the JDC350.500 double sleeper shaft force mixer: JS series: JS500.750.1000.1500.2000.3000.4000

- Q: How many tiles are in the concrete mixer on the site

- The power of the mixer motor on the site is 75KW

- Q: Concrete mixers need to be aware of which things

- Prior to the use of the new machine, the requirements of the manual of the concrete mixer shall be conducted according to the instructions of the concrete mixer, and the test and the necessary trial operation shall be conducted for each system and the parts. Running in the empty car, checking the rotation direction of the mixer or stirring leaves, the operation of each work unit, the brake, the confirmation of normal, the operation. Fixed concrete mixer should be installed on a strong pedestal. When used in the long term, the ground bolts shall be buried; If used in the short term, you can lay the sleeper and stabilize the sleeper. For mobile concrete mixer, it should be installed on flat and hard floor with square or supporting frame, and hold water flat tire. If more than three months should be used, the tire should be removed properly and the shaft end should be cleaned and rusted. For some mixers that need to be excavated, the ground of the pit should be strengthened to prevent the surface water from entering the pit. The bottom end of the material rail frame should be rammed or laid, and the back of the frame shall be supported by wood to prevent the deformation of the track during work. After the concrete mixer has been started, the mixing drum should be made up after normal speed and after loading, it should be added to the water in time. The new material must be removed before it can be removed. Do not start the blender when the load is stopped or full load, except for the reverser.

- Q: What is the difference between a concrete mixer and a mortar mixer

- Concrete is made by mixing several kinds of aggregates and water, cement and mixing. Because of containing coarse aggregate, and therefore require huge stirring power, also requires wear-resisting, so his stirring blades and liner is high chromium cast iron, or pieces, power is big, like JS500 will be 18.5 kw motor to drive! And the mortar is not contain coarse aggregate, so the power is very small, the power consumption is very low, do not need wear-resisting piece, appear easy and clever!

- Q: Is the concrete mixer and mortar mixer a machine

- The mortar mixer is the machine which mixes the cement, the sand and the aggregate with the water and mixed the mortar. It consists mainly of mixing, loading and unloading mechanism, water supply system, original motive, transmission mechanism, frame and supporting device. Mortar mixer equipment can meet the performance requirements of dry mortar, dry material, adhesive powder production needs, such as: putty powder, powder coating, masonry mortar, plaster mortar, insulation mortar, decorative mortar needed by the system and so on all kinds of dry powder mortar; And it has many advantages such as small area, little investment, quick results and easy operation. Working principle: when mixed machine work, inside the machine material subjected to two opposite direction of the rotor, with complex movement, the blades to drive the material aspect counterclockwise along the machine slot wall, on the one hand, drive material turning around, overlapping the two rotor shape floating zone, within the region, regardless of the shape of the material, size, and density, can make material floating instant weightlessness, which makes the material in the machine groove omni-directional continuous loop turn staggered shear each other, so as to achieve the effect of rapid mixing soft.

- Q: For example, what is the more detailed and better td-50 td-80 td-60

- Concrete mixer points generally mixer and forced mixer, currently used in engineering is forced, the difference is that the former is the shell in turn, the latter is in inside agitation. The most commonly used parts of a strong mixer are: hoisting bucket wheel, mixing arm, blade, hopper limiter, liner. Normally the mixing arm, blade, and lining plate for the vulnerable parts, should be replaced in time during construction.

- Q: What is the type of concrete mixer?

- There are 250, 350, 500 and so on, and the model is for his capacity. Is that satisfactory?

- Q: How much concrete the concrete mixer can stir at a time

- Different types of coagulant mixers and production are different; Zhengzhou in the morning with complete concrete forced mixer, 0.5 Fang Jiang type mixer, 0.75 square forced mixer, 1 Fang Jiang 1.5 Fang Jiang pattern type mixer, blender, 2 Fang Jiang type mixer and 3 Fang Jiang type concrete mixer, high output, low power consumption, low carbon environmental protection; 1, JS500 forced mixer (0.5 square mixer), stirring at 25 cubic concrete materials, to work an hour 26 degrees, and the power consumption is one of the lowest price in this type concrete mixer concrete mixing equipment. 2, JS750 forced mixer (0.75 square concrete mixer) per hour 35 cubic concrete mixing materials, work an hour 40 degrees, power consumption is the most popular on the market a concrete mixer. The JS1000 mixer (1 square machine mixer) produces 50 cubic meters of concrete per hour and consumes 51 degrees per hour. The JS1500 strong mixer (1.5-strong mixer) produces 75 cubic meters of concrete per hour and consumes 67 degrees in an hour. The JS2000 concrete mixer (two-square machine mixer) produces 100 cubic meters of concrete per hour per hour, and consumes 101 degrees for an hour. Zhengzhou middle morning concrete mixer quality assurance, service is carefree, satisfied various configuration way.

- Q: How does a concrete mixer operate

- If the machine is relatively new, the button will have, it's going to go up, go down, automatically add water, add water by hand, mix it up, mix it up, stop, vibrate

- Q: What is the difference between a concrete mixer, a JL type and a JW type?

- The jw-200 type mixer consists mainly of the main parts, such as the platform car, the motor, the gearbox, the feeding mechanism, the mixing mechanism and the feeding trough. After the electric start-up, the process of feeding, stirring and discharging is carried out through the transmission such as the triangle belt, the coupler and the worm gear reducer. The concrete mixer is small and suitable for underground.

Send your message to us

JS1000 concrete mixer

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords