Hot Rolled Mill Finished Aluminum Coils 1XXX

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

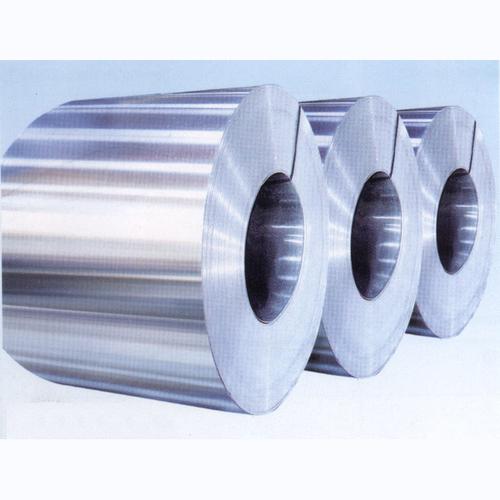

1.Structure of Hot Rolled Mill Finished Aluminum Coils 1XXX

Hot Rolled Mill Finished Aluminum Coils 1XXX is one semi-finished aluminium material. This strip can be rolled down to aluminium coil,sheet,circle ect. The alloy AA1050 is widly used in building, industry ect. Its weight is much lower than steel. So many customers choosed aluminium material instead of steel.

2. Main features of Hot Rolled Mill Finished Aluminum Coils 1XXX

a.Competitive price---We have our own mills and can produce mill finished aluminium coils, so we can control the production cost better.

b.Professional after-sale service---We have more than 15 years exportation experience and you need not worry about the exporation problems.

c.Fast delivery time---We can control the delivery time within 35 days.

3. Image of Hot Rolled Mill Finished Aluminum Coils 1XXX

4. Product Specification of Hot Rolled Mill Finished Aluminum Coils 1XXX

| ALLOY | TEMPER | THICKNESS | WIDTH | WEIGHT |

| AA5052 | H18 | 0.2MM-3MM | 1200MM-1800MM | 2 TONS |

5.FAQ:

What is the quality standard?

---Usually our standard is GB3880-2006

What is the largest width?

---It is 2300mm

What is the MOQ?

---Usually we can accept 80 tons.

- Q: Cast aluminum plate how to deal with a small hole

- Aluminum welding, you are there is a stomatal, welding process is not handled well. Strength certainly not reach, not to mention performance. There is no picture, look at the defect situation, I see can not remedy, think of ways to achieve its initial use of performance. Cast iron are recognized as difficult to weld it, this is a large cast iron machine arm after the fracture of the arm, the use of the scene, the accuracy of performance did not damage

- Q: What are the materials for making aluminum-plastic panels?

- Polyethylene core plastic polymer film Lvpi paint protective film

- Q: How to identify the quality of aluminum-plastic plate?

- And then cut a piece of the sample, boiled in boiling water for ten minutes, and then come out to put the refrigerator in the frozen one or two hours, if there is time to repeat more than a few times, and then hand or tools to expose the two sides of the aluminum, Opened the description of the quality is relatively poor, if it is not easy to open that excellent quality, which mainly depends on the temperature of hot and cold on the impact of aluminum panels.

- Q: OKorder aluminum-plastic composite board where to sell?

- Cloud like building materials have aluminum-plastic composite board sales

- Q: Aluminum-plastic board white, 1500 * 3000 how a small spot?

- What is the amount of this product is a small amount of product? How thick the product, aluminum plate thickness, surface paint requirements?

- Q: Aluminum-plastic plate pillars, slot depth and the tip of what is the relationship

- No direct relationship - depth is artificially adjustable! The style of the tip is related to the requirements of the slot - there are V, U and other shapes

- Q: Do aluminum-plastic plate wall, dry hanging way. Is a government project. There are 4,000 square meters. There are embedded parts. No frame, package package material how much appropriate ah

- No matter what kind of structure of the aluminum-plastic plate, 80 yuan / square meters is enough. The rest is the cost of artificial and accessories accessories.

- Q: Besides how to install aluminum-plastic panels, what is the process? What do you need?

- With expansion bolts hit the tile surface, and then steel angle code and angle or square tube fixed on the tile surface, and then the aluminum-plastic plate slotted 2MM side, with aluminum angle fixed in this 90-degree edge , According to the design of the installation specifications with bolts fixed on the tile surface installed in the steel pipe or angle above the sealant and then fill the seal between the aluminum-plastic plate and aluminum-plastic plate between the seam, tear off the aluminum-plastic sheet of the protective film can be The

- Q: When are the sets of layers? Which item is to be set?

- Composite panels, the implication of the products will be a lot of aluminum-plastic composite panels, aluminum honeycomb composite panels, copper and plastic composite panels.

- Q: Features of aluminum-plastic panels

- Aluminum-plastic plate is easy to process, forming a good material. But also for the pursuit of efficiency, for the time of the fine products, it can shorten the duration and reduce costs. Aluminum-plastic plate can be cut, cut, slotted, band saw, drilling, processing buried head, you can also cold bending, cold fold, cold rolling, can also riveting, screw connection or glue bonding.

Send your message to us

Hot Rolled Mill Finished Aluminum Coils 1XXX

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords