High quality wire rod 6.5mm-14mm SAE1008 and 1006

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 20000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

Product Description:

Specifications of Wire Rod SAE1008B:

Steel Grade: SAE1008B Standard: ASTM, GB

Diameter: 5.5mm, 6.5mm, 7mm,8mm,9mm,10mm,12mm,14mm

Type: Drawn Wire Alloy or Not: Alloy Brand Name: N-RIVER

Technique: Hot Rolled Place of Origin: China Mainland

Chemical Composition:

Please kindly find our chemistry of our material based on SAE1008B as below for your information

Grade | Chemical Composition (%) | |||||

C | Mn | S | P | Si | B | |

SAE1008B | 0.10max | 0.32max | 0.045max | 0.040max | 0.30max | 0.0008min |

Mechanical properties | ||||||

Yield strength(N/mm2) | Tensile strength(N/mm2) | Elongation (%) | ||||

≥195 | 350-380 | ≥32 | ||||

Usage and Applications of Wire Rod SAE1008B:

After hot-rolled the products shaped into coil and delivery as finished product, including round, square, rectangular, hexagonal and so on. Since most of the products are round, it is generally called wire rod. Carbon steel wire rod is widely used in construction and manufacturing. Carbon steel wire rod is mainly used for reinforcement of reinforced concrete and welded structure or reprocessed (roberts , nail, etc.) materials, especially used to produce wire drawing, welding electrode, nails, spring, electronic, precise machinery parts and so on.

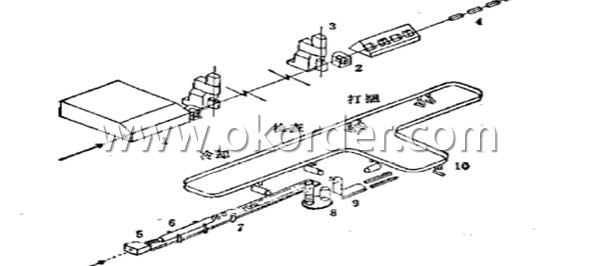

Production Process of Wire Rod SAE1008B:

1-Furnace 2-Roughing Mill 3-High-speed Finishing Mill 4-Water-cooled Device 5-Coiling Device

6-Cooling Device 7-Chain Conveyer 8-Spool Collecting Device 9-Spool Down Device 10-Hook Conveyer

Packaging & Delivery of Wire Rod SAE1008B:

Packaging Detail: products are packed in coil and then shipped by container or bulk vessel

Each coil weight: 2-3MT

Delivery Detail: within 45 days after received deposit or LC.

Label: to be specified by customer, generally, each bundle has 1-2 labels

Trade terms: CFR, CIF

Wire Rod in Container

Wire Rod in Bulk Vessel

Note:

1. Our products are produced according to national standard (GB), if not, supply according to national standards (GB) or agreement as customer required.

2. Other Grade and Standard carbon steel wire rod we can supply:

Grade: H08A, 30MnSi, 62B-82B

Standard: AISI, BS, JIS, DIN

The Minimum Order Quantity of these products is high, and need to be confirmed.

3. We can not only supply carbon steel wire rod; if you need anything about building materials, please contact us.

4. Please send us your detail specifications when inquire. We will reply to you as soon as possible. We sincerely hope we can establish a long stable business relationship.

- Q: How is steel wire rod used in the manufacturing of wire forms for musical instruments?

- Steel wire rod is an essential component in the manufacturing of wire forms for musical instruments. It serves as the base material for creating various wire shapes, such as springs, hooks, and braces, which are crucial for holding instrument parts together or providing tension. The high-quality and strength of steel wire rod ensure durability and reliability in these wire forms, enabling musicians to produce precise and harmonious sounds from their instruments.

- Q: How is steel wire rod used in the manufacturing of wire forms for ski lifts?

- Steel wire rod is used in the manufacturing of wire forms for ski lifts as it provides the necessary strength and durability required for supporting the weight of the ski lift cabins and passengers. The wire rod is typically shaped and formed into various components such as cables, ropes, and pulleys which are then assembled to create a secure and reliable system for transporting skiers up the slopes.

- Q: What are the common disposal methods for steel wire rod?

- The common disposal methods for steel wire rod include recycling, repurposing, and landfilling. Recycling involves melting down the wire rod to create new steel products, reducing the need for raw materials. Repurposing involves finding alternative uses for the wire rod, such as crafting or construction. Landfilling is the least preferred method, but sometimes necessary when the wire rod cannot be recycled or repurposed.

- Q: What are the main factors affecting the market collaborations of steel wire rod?

- The main factors affecting the market collaborations of steel wire rod include the demand and supply dynamics of the steel wire rod industry, the level of competition among market players, the cost of production and raw materials, technological advancements, government regulations and policies, and economic factors such as GDP growth and inflation rates. Additionally, factors like market trends, customer preferences, and global trade dynamics also play a significant role in shaping market collaborations in the steel wire rod industry.

- Q: What are the main applications of steel wire rod in automotive manufacturing?

- Steel wire rod is widely used in automotive manufacturing for various applications. One of the main uses is in the production of tires, where steel wire rod is used as reinforcement material to enhance the strength and durability of tires. Steel wire rods are also used in the manufacturing of springs, such as suspension springs and seat springs, which provide stability and support to the vehicle. Additionally, steel wire rod is utilized in the production of automotive cables, such as brake cables and clutch cables, due to its high tensile strength and excellent resistance to corrosion. Overall, steel wire rod plays a crucial role in automotive manufacturing by providing essential components that ensure the safety, performance, and reliability of vehicles.

- Q: How is steel wire rod used in the manufacturing of fences?

- Steel wire rod is used in the manufacturing of fences as it serves as the primary raw material for producing the wires used in fencing. The wire rod is typically drawn into thin wires, which are then processed, coated, and woven into various fence designs. The strength and durability of steel wire rod ensure that the fences are sturdy and long-lasting, providing security and boundary demarcation in residential, commercial, and agricultural applications.

- Q: What are the specifications for steel wire rod used in offshore wire strands?

- The specifications for steel wire rod used in offshore wire strands are typically determined by industry standards and regulations. These specifications are designed to ensure the safety and reliability of the wire strands used in offshore applications. Some of the key specifications for steel wire rod used in offshore wire strands include: 1. Material composition: The steel wire rod used in offshore wire strands should be made from high-quality carbon steel or alloy steel. The material composition should meet specific requirements in terms of strength, durability, and corrosion resistance. 2. Tensile strength: The wire rod should have a high tensile strength to withstand the heavy loads and stresses experienced in offshore environments. The required tensile strength may vary depending on the specific application and project requirements. 3. Diameter and tolerance: The wire rod should have a specific diameter and tolerance to ensure compatibility with the wire strand manufacturing process. The diameter and tolerance may vary depending on the wire strand design and application. 4. Surface finish: The wire rod should have a smooth surface finish to facilitate proper adhesion and bonding with the surrounding materials, such as resin or protective coatings. The surface finish should also be free from any defects, such as cracks or scratches, which could compromise the performance of the wire strand. 5. Corrosion resistance: Offshore environments are exposed to harsh conditions, including saltwater, moisture, and corrosive elements. Therefore, the steel wire rod used in offshore wire strands should have excellent corrosion resistance properties to prevent degradation and maintain structural integrity over time. 6. Certified testing and quality control: The wire rod should undergo rigorous testing and quality control measures to ensure compliance with industry standards and specifications. This may include testing for mechanical properties, chemical composition, surface finish, and corrosion resistance. It is important to note that the specific specifications for steel wire rod used in offshore wire strands may vary depending on the project requirements, industry standards, and local regulations. Therefore, it is essential to consult the relevant codes and standards applicable to the specific offshore application to determine the exact specifications for the wire rod.

- Q: How is steel wire rod used in the production of wire mesh for mining and quarrying applications?

- Steel wire rod is used in the production of wire mesh for mining and quarrying applications by being drawn into thin wires and then woven or welded together to create a strong and durable mesh structure. This mesh is then used to reinforce tunnels, protect equipment, and provide safety barriers in mining and quarrying operations.

- Q: What are the different surface treatment processes used for steel wire rod?

- Steel wire rod undergoes various surface treatment processes to enhance its corrosion resistance, improve its aesthetic appearance, or provide specific functional properties. One commonly used process is galvanizing, where a layer of zinc is applied to the steel wire rod. This protective layer acts as a sacrificial anode, corroding instead of the steel and preventing corrosion. Galvanizing can be achieved through hot-dip galvanizing or electroplating, depending on specific requirements. Phosphating is another surface treatment process that involves applying a phosphate coating to the steel wire rod. This coating improves adhesion of subsequent coatings or paints, enhances corrosion resistance, and increases wear resistance. Electroplating involves depositing a layer of metal onto the steel wire rod's surface using an electrolytic cell. Various metals like zinc, nickel, or chromium can be used to provide corrosion resistance, enhance aesthetics, or improve specific properties such as hardness or conductivity. Heat treatment processes like annealing or quenching and tempering can modify the microstructure of the steel wire rod's surface. These processes improve mechanical properties like strength, ductility, and toughness. Surface coating processes like powder coating or paint application are also used for steel wire rod. These processes provide aesthetic appeal, protect against corrosion, or improve friction characteristics. The choice of surface treatment process depends on the desired outcome and specific application requirements. Whether it is for corrosion resistance, improved aesthetics, enhanced mechanical properties, or functional purposes, these treatment processes play a crucial role in ensuring the performance and longevity of steel wire rod in various industries.

- Q: How is steel wire rod used in the manufacturing of wire for automotive fuel injection systems?

- Steel wire rod is used in the manufacturing of wire for automotive fuel injection systems as it provides the necessary strength and durability required for this critical application. The wire rod is first processed through various stages such as drawing and annealing to achieve the desired diameter, surface finish, and mechanical properties. This wire is then further processed and formed into intricate shapes and components, such as fuel injector springs, connectors, and terminals, which play a vital role in ensuring efficient fuel delivery and system performance.

Send your message to us

High quality wire rod 6.5mm-14mm SAE1008 and 1006

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 20000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords