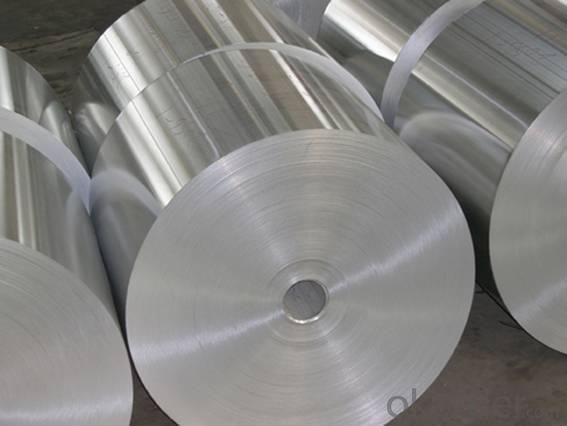

High Quality Aluminium foil Coil Aluminium Container

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1) Material: PET/AL/NY/PE, PET/NY/PE, PA/PE as clients' required and with custom thickness.

2)variety sizes: 20cmX15m, 28cmx6.5m for rolls, and 10x14 inch, 13.5x20inch, 8x12 inch for bags or customized sizes.

3) All colors are available: Up to 12 colors and can be custom-made, plate cost is based on their sizes and artworks (AI, or PDF, EPS formats are faster and clearer to do plates, JPG File over 300kb also is good for us).

4) MOQ: 10,000 pcs, production time is 10-12 days. Stock bags could be in a very lower quantity.

5) Type: 3 side seal bags, ziplock bags, stand up bags, rolls

6) Feature:

a Strong sealing, High tensile strength, good carrying capacity.

b All materials are eco-friendly.

c Glossy printing, sharp color, durable print

d Easy opening with reclosable zipper

e Cost effective

f nnovative design to enhance marketability and visibility

g With E holes or round holes to make cosmetic bags hanging easily

h Recyclable (Bio degradable)

7) Applications:

a Solid Contents for Foods: Candy, Biscuit, Potato Cracker, Spice, Soup Powder, Vegetable, Chocolate, Jerky, Pet Foods, Croutons, and more

b Solid Contents for Cosmetic and Washing Powder and Other Industry Use: Washing Powder, Lawn Weed Control Granule, Meadow Grass Mixture, Ant-killer Granule, and more

c Dried Foods: Potato Chip, Raisin, Snack, and more

d Liquid Contents: Juice, Drink, Mineral Water, Sauce, Ketchup, Milk, Skin Care, Soap Liquid, Detergent, Paste, Cream, Tea, Coffee, Shampoo, Edible Oil, and more

8) Producing process: Mould/Cylinders making, printing, laminating, separating and cutting, bag making, inspection, packing in cardboard box

9)Samples are available: finished similar samples or do samples in clients’ specification about 8-10 days

FAQ

Q1:Do you provide sample? How many days will samples be finished?

Free samples will be provided if needed, but customers should undertake shipping cost or freight charges, samples will be finished in 5-7days

Q2: Can we visit your factory?

Welcome to our factory at any time.

Q3: Complaint solving process

Finding your salesman—Salesman provide you the solution (If it’s our responsibility, we will resend substitutes or return money or provide discount for your next order, etc.; If it’s shipping company’s responsibility, we will also help you until the problem is resolved.) —If salesman can’t solve your problem, please call our manager .

Q4: Delivery time

3~30working days after confirming the payment. If the order is urgent, we will push our workers to finish in advance.

Q5: What's your MOQ?

Normally 8MT are requested as the minium order quantity ,we shall give

additional instructions in special circumstances.

Q6: What are the terms of payment and currencies do you accept?

T/T or L/C is accepted, currently we appreciated your payment through

USD,EUR, RMB

Q7: Do you accept customized orders?

Yes, we do. Your customized orders are always welcomed. Please kindly offer us your samples or drawings, so that we can customize the products according to your preferences. About any further detail, please feel free to contact us.

Q8: What information should I let you know if I want to get a quotation?

Your detailed requirements regarding the products's dimensions, including shape, thickness, top out (length*width*height), and your order quantity are highly appreciated if you want further information about our quotation

Q9: How about the mass production?

The lead time of mass production depend on quantity, usually 25-30days (20FT).

- Q: Plastic pad hot stamping how to deal with?

- The hollow part shall be resisted from the inner side of the product, and the pressure on the hot stamping surface shall be kept uniform(1) the stamping temperature is too high. Should be properly lowered.(2) the heating body of rubber board, mould and rubber roller is too close to the stamping foil. The distance between heating body and hot stamping foil should be appropriately increased.(3) the stamping time is too long. Should be appropriate to shorten the surface of hot stamping, loss of light, dark(1) the stamping temperature is on the high side. Should be properly lowered.(2) stamping time is too long. Should be properly shortened.(3) the distance between hot stamping foil and heating body is too small. Should be appropriate to increase the stamping layer wrinklesDoor, rubber, printing, touching, rubber roller and stamping foil too close. Appropriate distance should be drawn.(2) the temperature of rubber sheet, mould and rubber roller is too high. Should be properly lowered.(3) the parts of the window, such as the window, not the tire clamp, the uneven stamping pressure. Products should be hollow place pad, so that the stamping pressure to maintain uniform.(4) the hot stamping foil is not smooth. Foil delivery device shall be checked.(5) the surface tension of hot stamping foil is too small. Should be increased tension, tighten the foil, partial leakage of foil, leakage and surface spots

- Q: Hot stamping materials

- The first layer is the base film layer, also known as the film base, which supports the role of other layers, the thickness of 12, 16, 18, 20, 25 polyester film or polyester.The second layer is the isolation layer (separation layer), which is convenient for the separation of the basement membrane and the anodized aluminum foil during hot stamping.The third layer is the dyeing layer (protective layer): provide a variety of color effects, while protecting the aluminum layer.The fourth layer is aluminized layer: reflecting light, showing metallic luster, adopting vacuum aluminium plating method. The specific principle is coated with color film, in a vacuum vacuum continuous aluminium in indoor machine, in a certain vacuum, by resistance heating, aluminum wire melting and continuous evaporation into the film layer, formed the aluminized layer.

- Q: What's the reason for the lack of stamping or stamping?

- Printing printing ink layer too thick: color ink layer thick substrate, the substrate surface will prevent the adsorption of aluminum foil stamping of the adhesive, the foil adhesion decreased, resulting in hot stamping or not.

- Q: What is the working principle of the gilding press?

- Introduction to the working principle and classification of gilding pressThe principle is to have the color of gilding bronzing paper bronzing paper to cover your substrate through the above pressure, time adjustment, glue layer its subsequent stamping paper through temperature and pressure to combine with the substrate, and then through the foil layer and the base layer and some from each other from the rest the glue layer, plating layer, color layer used in your substrate to the above.

- Q: What is the principle of anodized aluminum printing of different colors of aluminum layer to the surface of printed matter?

- Anodized hot stamping process are as follows: through hot stamping anodized aluminum version makes the heating, melting and stripping layer, adhesive layer is melted in nano imprint lithography adhesive layer and substrate bonding, the colored layer and the polyester film base from the aluminizing layer and the coloring layer in the substrate.

- Q: What is the structure of anodized aluminium foil?

- From the opposite to the front substrate, followed by the isolation layer (also called stripping layer), protective layer (also called the colored layer), aluminium layer and adhesive layer.

- Q: What's the use of hot stamping paper?

- With the rapid development of stamping foil and packaging industry, the application of anodized aluminum is more and more widely. Such as: book cover bronzing, gift boxes, wine, bronzing, smoke clothing trademarks and box bronzing, greeting card, invitation cards, pen bronzing etc., its color and pattern, also can be customized according to the specific requirements of zhuanban. Hot stamping of the substrate, including general paper, gold, silver, ink and other printing ink, printing paper, plastics (PE, PP, PVC, engineering plastics, such as ABS), leather, wood and other special materials.

- Q: How many anodized aluminum foils does a standard volume of anodized aluminum foil require?

- With the advent of new materials such as anodized aluminum, real gilding and hot silver are widely adopted in the printing and decorating industry. China's earliest use of hot stamping materials are sheet metal foil and powder, anodized aluminum foil is 2.

- Q: UV printing can also be hot stamping

- Take the sprinkler, sprinkler Ricoh G5 will be more than 20000, while the Toshiba CE4 is only about 6000, Toshiba life of 24-36 months, the printing speed, but the accuracy of the Toshiba CE4 Ricoh than G5 high, Toshiba head warranty of two years, which determines the process of using the printer in the future whether the problem of increasing cost

Send your message to us

High Quality Aluminium foil Coil Aluminium Container

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches