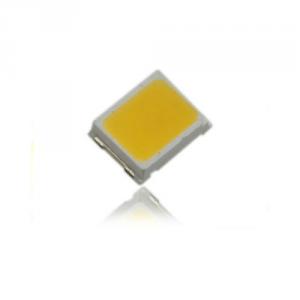

high efficiency 2835 light emitting diode LED

- Loading Port:

- Shekou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 4000 PCS

- Supply Capability:

- 1800000 PCS/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Features & Benefits

- Package: 3.5*2.8*0.65mm (Top view white LED)

- Emitted Color: White

- Soldering methods: All SMT assembly methods

- Enables 3-, 4-, 5-step MacAdam ellipse kits

2. Typical Application:

- Bulb

- Indoor & Outdoor sign board back light

- Advertising backlighting

- General use.

3. Precautions for use

3.1 Soldering

SMD LED encapsulation is very flexible, outside force easily demolish radiant surface and plastic, As soldering , Please handle with care!

a. With No-clean Flux, according to reflow soldering cure condition when soldering, Reflow soldering should not be done more than two times, simultaneity you must insure clean on the radiant surface. Otherwise, foreign objects can affect radiant color.

b. Don’t process manual soldering except repair. Recommended to be soldered with 25W Anti-static iron, The temp. of the iron should be lower than 300℃ and soldering time should not be done more than three seconds, at the same time iron can’t touch radiant surface and plastic.

c. Don’t twist LED in course of manual soldering and experiment, Otherwise, the lights will not work possibly.

d. Please use the same BIN grade in one panel, and don’t mix the difference BIN grade in one panel when soldering. Otherwise, it will cause a serious uneven color problem.

e. Please control the sulfur content of solder paste and PCB.

f. Pb-free solder temp.-time profile as below:260℃Max.

3.2 Cleaning

a. Don’t be cleaned with ultrasonic. Recommended to be wiped with isopropyl alcohol or pure alcohol, wiping time should not be more than one minute. LED must be placed at room temperature for fifteen minutes before producing .you must insure clean on the radiant surface. Otherwise, foreign objects can affect radiant color.

b. LED can’t be in contact with acetate、trichloroethylene,acetone、sulfur、nitride、acid、alkali、salt.These matters can destroy LED.

3.3 Sealing

a. Sealing glue can’t contain sulfur,because these matter can affect fluorescence powder poisoning.

b. When using normal sealing glue, recommended will be operated life for 168hrs under normal temperature.

3.4 Storage

a. Don’t open the moisture proof bag before ready to use the LEDs.

b. The LEDs should be kept at 30℃ or less and 60%RH or less before opening the package. The max. period before opening the package is 1 year.

c. After opening the package, the LEDs should be kept at 30-35%RH or less, and it should be used within 3 days. If the LEDs should be kept at 30-35%RH or more, and it should be used within 4 hours.

d. If the LEDs be kept over the conditions of 20%, baking is required before mounting. Baking condition as below: 70±5℃ for 12 hours for bulk goods, 105±5℃ for 1 hours for roll goods.

e. The environment have no acid、alkali、corrosive gas、intensively shake and high magnetic field.

3.5 Static

a. Static and Peak surge voltage can destroy LED, Avoiding Instantaneous voltage when turn on or turn off the lights.

b. Please wear Anti-static wrist band、Anti-static glove、Anti-static shoes in the course of operation, and the equipment must be grounded.

c. After LED is be destroyed, leakage current increase obviously, and it will be forward voltage falling or failure lamp in the case of low current.

3.6 Test

a. Customer must apply the current limiting resistor in the circuit so as to drive the LEDs within the rated current. Otherwise slight voltage shift maybe will cause big current change and burn out will happen.

b. Also, caution should be taken not to overload the LEDs with instantaneous high voltage at the turning ON and OFF of the circuit.

c. The reverse voltage mustn’t exceed 5v when lighting on or testing the LED,otherwise, LEDs will be damaged.

3.7 Else

Radiant color of LEDs will be a little change with the current, recommended that LED is be used in series and resistance, when lighting, please don’t see directly radiant surface of LED, otherwise LED will burn eyes.

- Q: Production of a number of substrates, the use of SMD LED lights, red lights and green lights are not bad, blue lights appear mass dark, do not know why? Is the LED blue light material easy to use dark?

- When making a batch of LED lights, the brightness values of various lights are in accordance with certain rules. Due to achieve a white balance, three RGB color brightness required by the ratio of 3:6:1, that is to say the blue light required brightness is very low.

- Q: Indoor full color LED display module and LED what is the difference between a full color?

- The classification of the LED display according to the installation environment: indoor LED display screen, semi outdoor LED display, outdoor LED display; according to color: color LED screen, dual color LED display screen, LED display screen, the color LED display screen; according to the functional area can be divided into graphic screen, screen, screen, screen, digital dot matrix digital hybrid screen.

- Q: Is the forward voltage drop of the patch LED too large or too small?

- The pressure drop in the normal range is generally better. The smaller the pressure drop, the lower the power dissipation. The more you save the electricity bill.But not to say that the smaller the better, not in the normal range of low pressure drop products may be defective.In addition, the uniformity of the LED pressure drop is also important.

- Q: Patch LED light does not flash, why?

- Light emitting diodes, referred to as LED. Made from compounds containing gallium (Ga), arsenic (As), phosphorus (P), nitrogen (N) and so on.When electrons and holes are combined, they can radiate visible light, so they can be used to make light-emitting diodes. In circuits and instruments, as an indicator, or in combination with text or digital display. GaAs diodes glow diode gap, green silicon carbide, yellow light diode, light emitting diode gan. Because of the chemical properties and organic light-emitting diode OLED and inorganic light-emitting diode LED.

- Q: Which is good for LED patch and LED bulb?

- The LED patch is the same as the LED bulbLED (light emitting diode) patch (package)The LED patch (SMD) is made of FPC circuit board, LED and high quality silica gel sleeve. Waterproof performance, using low voltage DC power supply is safe and convenient, light colors, bright colors; outdoor use can be anti UV aging, yellowing, high temperature resistance and other advantages, the products are widely used in building lights, decorative lighting, advertising and entertainment quasi decorative lighting lighting field.LED bulbWith the LED patch or LED plug-in LED (light emitting diode), series or parallel, driving power supply, making a combined shell lampshade capable of converting electrical energy into visible solid semiconductor devices, which can be directly converted into electricity to light.

- Q: Patch LED market conditions

- With good market expectations for the future status of SMD LED, all the major manufacturers have launched their own SMD LED development planning and prototype products, all of a sudden, SMD LED market showing a flourishing and lively atmosphere of contention of a hundred schools of thought.

- Q: What is patch LED?

- LED is usually the lead pins form, need to be drilled on the printed circuit board, the LED pin is inserted in the hole, welded with wave soldering machine; and the patch type LED is used in welding surface, flat welded on the circuit board.

- Q: The quality of the LED patch module

- Life。 LED's life is considered 100000H. In fact, LED products in 10 or 20 years to reach 100000 hours, and now the best LED life expectancy is only 50000 hours. Incandescent lamp for 1000 hours, fluorescent lamp for 2000 hours, neon for 10000 hours. The so-called "100 thousand hours" was only measured by scientists at room temperature at room temperature. After the formation of LED and chip packaging products, even the top of the chip, due to differences in the production of advanced packaging using the equipment, technical differences, the different forms of packaging, management, as well as the difference between the way users, resulting in life are not the same. Patch LED, life can reach 40000-50000 hours; piranha LED, life expectancy of 30000 hours, inline LED, life expectancy is 10000 hours. Of course, with the advances in chip and packaging technology, these data will gradually increase. The premise is that you understand an important concept, LED life means when the brightness of LED is 70% of the original brightness, we decide the LED life to this end.

- Q: What does "1210" mean in patch LED?

- 1210 refers to the lamp specifications.LED common lamp specifications and parameters of patch0603, 0805, 1210, 3528, 5050 refers to the LED lamp belt, often used in light-emitting components ----LED size (English / Metric) name, for example, 0603 refers to the length of 0.06 inches, width of 0.03 inches. But note that the 3528 and 5050 units are metric

- Q: Such as title, please have welding patch LED lamp experience expert guidance, do not search from the Internet to the theoretical knowledge, thank you!

- If the power of the lamp, because heat high power do very well, so not good welding, the temperature at the highest (300 degrees), the use of horseshoe iron head, not waiting to solder, because the heat is very powerful, quick action.

Send your message to us

high efficiency 2835 light emitting diode LED

- Loading Port:

- Shekou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 4000 PCS

- Supply Capability:

- 1800000 PCS/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords