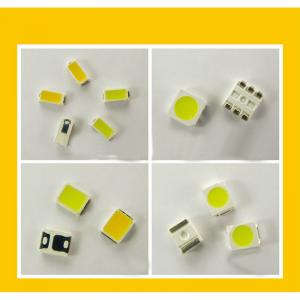

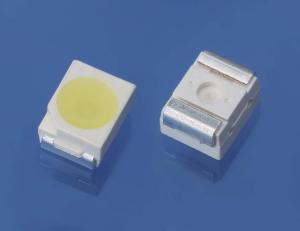

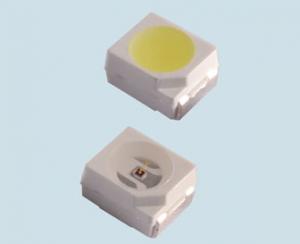

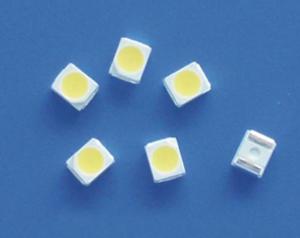

G4 SMD LED

- Loading Port:

- Guangzhou

- Payment Terms:

- L/C,T/T

- Min Order Qty:

- 100 Pcs pc

- Supply Capability:

- 100000 Pcs Per Month pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

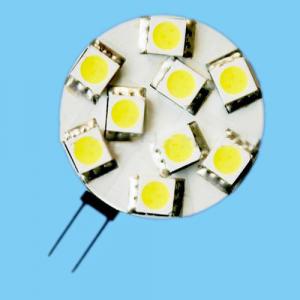

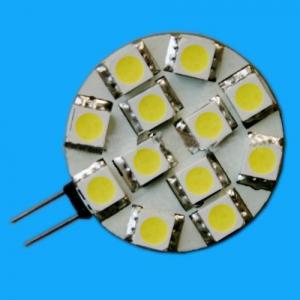

| G4 LED/LED G4/G4 smd LED | Type | Size | Lumen | Color |

1.NO.:TL-G4P312

| TL-G4P312-3×1.5W | 9*(24×24) | 200-210Lm | white |

TL-G4P312-3×1.5B | 9*(24×24) | 30-35Lm | blue | |

TL-G4P312-3×1.5R | 9*(20×20) | 175-185Lm | red | |

TL-G4P312-3×1.5Y | 9*(20×20) | 170-180Lm | yellow | |

TL-G4P312-3×1.5G | 9*(20×20) | 170-180Lm | green |

Delivery:

Shipping Service | Estimated Delivery Time |

DHL | 2-8 business days |

FedEx | 3-8 business days |

TNT | 2-10 business days |

UPS | 1-7 business days |

EMS | 6-14 business days |

ePacket | 7-12 business days |

China Post Air Mail | 7-15 business days |

China Post SAL | 14-30 business days |

By Sea | 30-40 business days |

1. 3-5 business days for Sample Orders; 7-15 business days for Bulk Orders for Bulk Orders.

2. "Business days" means Monday-Friday, excluding holidays.

3. DHL and UPS cannot ship to military or P.O. boxes address

4. The Shipping Service above is for reference only, for any other questions, please feel free to contact us.

- Q: Production of a number of substrates, the use of SMD LED lights, red lights and green lights are not bad, blue lights appear mass dark, do not know why? Is the LED blue light material easy to use dark?

- The pressure drop of the blue light is greater than that of the red light and the green light. If the series connection is the same as that of the green light and red light, the current limiting resistor will tend to dim

- Q: What should I notice when I want to solder 1206 LED patch type luminous tube on fine copper wire?,

- The peak reflow temperature: 260 degrees or below this temperature. (surface temperature) 2 temperature over 210 DEG C required time: 30 seconds or less than this time. 3 reflow times: no more than two times. 4 after reflow, LED needs to be cooled to room temperature before contact with colloid.

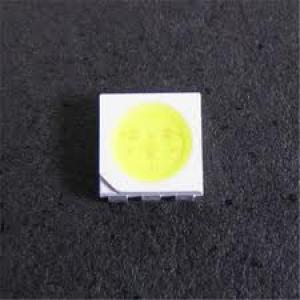

- Q: How does the LED placement lamp distinguish the positive and negative poles? There is no sign on the light. Thank you

- The light emitting diode is fixed regardless of color. The light emitting diode 1, line: foot length is positive, the negative is short. The electrodes inside the tube can also be carefully observed, while the smaller ones are positive and the large ones, similar to the bowl, are negative. 2, SMD: overlooking the side with the color line is negative, the other side is positive.

- Q: What, in what way do I shunt the LED?

- The voltage problem is determined by the size of your POWER SUPPLY, according to Ohm's Law: the series voltage is accumulated and the shunt voltage is the same.

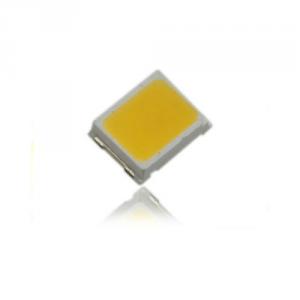

- Q: What is patch SMD-LED?

- SMD LED is the surface mount light emitting diode. It is a solid state semiconductor device that converts electricity directly into light. The heart of LED is a semiconductor wafer, one end of which is attached to a bracket, one end is negative, and the other is connected to the positive electrode of the power to encapsulate the entire wafer with epoxy resin.

- Q: The quality of the LED patch module

- Luminous efficiency。 The LM value per watt is called luminous efficiency. This is an important criterion for judging whether LED is energy-saving or not. The incandescent lamp is about 14.4LM/W, the fluorescent lamp is about 51LM/W, the neon lamp is 43LM/W or so, and the LED is up to 150LM/W at present, but most of the LED light effects in our country are in 60~100LM/W. It should be noted that only the white light can achieve such high luminous efficiency in LED, and that red, yellow and blue are generally relatively low (mainly related to human visual definition). But compared with neon light, there is no heavy metal pollution, easy to maintain.

- Q: LED package and LED SMD LED lamp, what is the difference? Will the release agent be used in that part?

- They differ in form and belong to the SMDLED category. Encapsulation uses liquid silicone and epoxy resins as well. The patches are basically made of epoxy resin. Relatively speaking, the amount of liquid silica should be relatively large.

- Q: Patch LED light broken one, short circuit can use it?

- Can not casually short-circuit, according to the LED connection, but also to see the power supply voltage and current, all the LED can not flow. Any short circuit may cause excess LED to flow over or over, causing a chain reaction, a bad string,...... .

- Q: How do led patches measure good or bad?

- Use the two stage tube test of the multimeter, the red pen is connected, and the black pen is negative. If there is a bee, the sound is bad, and if the light is bright, it is good

- Q: Such as title, please have welding patch LED lamp experience expert guidance, do not search from the Internet to the theoretical knowledge, thank you!

- When soldering, the temperature is best to be lower, and the average welding temperature is about 360. That's enough, because the melting temperature of the tin wire is about 220 degrees, so if it is allowed, the temperature can be reduced as low as possible.

Send your message to us

G4 SMD LED

- Loading Port:

- Guangzhou

- Payment Terms:

- L/C,T/T

- Min Order Qty:

- 100 Pcs pc

- Supply Capability:

- 100000 Pcs Per Month pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords