Food Packaging Aluminium Foil with/without Zip Lock Bag

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

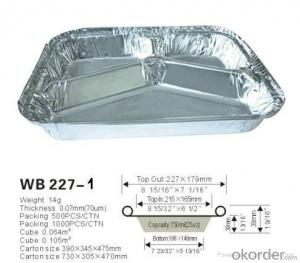

Specification

Quick Details

| Temper: | Soft | Use: | Food | Treatment: | Printed |

| Type: | Roll | Alloy: | 1280 | Thickness: | 70-100mic |

| Place of Origin: | Brand Name: | Model Number: | |||

| shape: | in bag | color: | up to 10 colors | advantage: | printing clear |

| core: | 76mm paper core | size: | customized |

Packaging & Delivery

| Packaging Details: | for Vacuum Aluminum foil bags,2000 pieces in a carton,24catons a pallet or as buyer's requirements (Different products are diversely packed according to the weight.) |

| Delivery Detail: | within 20-25 days |

Delivery time: 20-25days (According to order)

Sample : For the ready sample,we can provide about 2-3days;

But for the new design sample we need 7 working days

(Buyers need to pay the sample charge)

When you contact me Please kindly inform us the materials, thickness, size, printing colors and other special requirement of your product. So that we can give the satisfactory service

- Q: What causes the explosion of liquid nitrogen container liquid nitrogen tank?

- Liquid nitrogen is a special industrial product, which has the characteristics of ultra low temperature, expansion, odorless and non-toxic. With the wide application of liquid nitrogen in precision industry, medicine and food, more and more accidents occur in liquid nitrogen container when filling and storing liquid nitrogen. The explosion of liquid nitrogen container causes damage to the equipment, which can lead to casualties. So what are the main causes of the explosion of liquid nitrogen container liquid nitrogen tank?.

- Q: The working principle and characteristics of hand held aluminum foil sealing machine

- The machine can be divided into two parts: the control box and the output induction head. 100KHZ high frequency current generated by the microcomputer control source by amplifying, shaping, push the power module output to the sensor head, when the metal aluminum foil container Gary proximity sensing head, eddy current heating on the aluminum foil, heating degree by the intensity and duration of the short length to determine eddy current. The whole machine is equipped with an automatic frequency stabilizing circuit, the function time can be adjusted and the working status can be displayed. This machine has been improved to slow the sealing speed of the 500A model, so that the machine can be continuously heated by heating without stopping once. Therefore, the sealing speed of the machine is much faster than that of the 500A model.

- Q: Relationship between capacitor capacity and aluminum foil

- If it is the gold film capacitor, the medium is the film, the voltage is high, the medium is more, so the capacity is not only related to the area of the aluminum foil, but also to the thickness of the dielectric. Generally speaking, if the voltage is determined, the larger the area of the aluminum foil, the greater the capacity!

- Q: Can the aluminum foil bowl be heated by microwave oven?

- Well, yes, some foil boxes can be heated directly in a microwave oven

- Q: Plastic container for food packing container

- Composite film bag: made of different kinds of plastic film or laminated with plastic film and paper and aluminum foil. According to the use and requirements, it can be made of two layers, three or more kinds of composite film bags. Such as polyethylene - polyester, cellophane - polyvinylidene chloride, polyethylene two - polyethylene, paper, polyester - aluminum foil - polyolefin, polyethylene - aluminum foil - paper - polyethylene - polyamide film bags. By hot lamination, coating, adhesive, CO extrusion method for processing and preparing, with special adhesive between layers. One of the typical representatives of composite film bags is a retort pouch for high temperature sterilization. It has excellent isolation, can long-term preservation of food, not deterioration, there are soft canned. The composite material is based on polyester aluminum foil polyolefin. The composite film bag can also be applied to aseptic packaging process, and the full-automatic production line of container forming, food filling and sealing can be successfully realized by using composite material. The recently emerging boxes, bags and barrels are the first aseptic packaging containers developed in the United Kingdom for packaging liquid and mushy foods, such as wines, juices, ketchup, etc.. The packing bag is made of plastic and aluminum foil, and the volume is 5, 20, 200, 220 and 1000 liters. Filling under aseptic conditions, into the corrugated box (5 ~ 200 liters bag) or wooden box (1000 liter bag), called the box into the bag; if the drums (220 liters), it is called barrel bag. Its common feature is convenient storage and transportation.

- Q: What is the material of aluminum foil

- Because of its soft texture and good ductility, it has a silvery luster. If the rolled sheet is made of sodium silicate on the offset paper, the foil can be printed. But the aluminum foil itself is easy to oxidize and the color is dull, friction, touch and so on will fade. Therefore, it is not suitable for the long-term preservation of books, covers and other hot stamping.

- Q: Pan middle foil cake is not able to stick?

- If you are using a cake powder, water and mix thoroughly, add vegetable oil and stir evenly, put aluminum foil paper folded into a square container, will adjust the good batter down on the inside, the aluminum foil containers placed in the oven, the oven on it. Foil foil will be all right.

- Q: Hand held aluminum foil induction sealing machine, how long is the sealing time?

- Handheld aluminum foil sealing machine use environment:Handheld foil sealing machine maximum ambient temperature 45 degrees centigrade, relative humidity not higher than 80%, the machine should be placed in a well ventilated environment, cooling hole induction power supply side and bottom heat radiating holes and inductive head to ensure clean and smooth. Excessive temperature or humidity will have a great impact on the life of electronic components, and even lead to damage to the equipment.

- Q: Dcgy-500 type aluminum foil sealing machine is out of order, it is not sealed, burned out which element, how to fix?

- Recommend a small number of products, practical handheld aluminum foil sealing machine. It is the first choice for small businesses to save equipment costs. This machine can adjust sealing power according to sealing size. The bottle neck can be used between 20 and 100 millimeters in diameterHandheld aluminum foil sealing machine use environment:Handheld foil sealing machine maximum ambient temperature 45 degrees centigrade, relative humidity not higher than 80%, the machine should be placed in a well ventilated environment, cooling hole induction power supply side and bottom heat radiating holes and inductive head to ensure clean and smooth. Excessive temperature or humidity will have a great impact on the life of electronic components, and even lead to damage to the equipment.

- Q: Where is the use of high pressure etching into electronic aluminium foil?

- China's electrolytic aluminum capacitor development is also very fast, according to statistics, in 1997 production of about 15 billion, it is estimated that in the near future may have more than 20 billion. Judging from the development of China's electronic industry, the output of aluminum electrolytic capacitors will be greatly improved in recent years. At present, some parts of China's electrolytic capacitor foil are made in China, and a considerable number of them rely on imports.

Send your message to us

Food Packaging Aluminium Foil with/without Zip Lock Bag

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords