Aluminium Foil Mylar Tape For Cable Shielding from CNBM

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 300 kg

- Supply Capability:

- 400000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Aluminum Foil Facing Description:

The production technologies and products performance of aluminum foil facing have been up to international advanced level. The aluminum foil facing products are mainly used for HVAC system, refrigerators, building thermal aluminum foil facing insulation and laminated with glass wool and rock wool to increase the insulation function.

• Heat-sealing aluminum foil facing is used for duct wrap without applying extra adhesive and suitable for online lamination of glass wool and rock wool.

2.Main Features of the Aluminum foil facing:

• Small inertia resistance

• Strong heat dissipation ability

• Good visual effect

• High reflective insulation

• Heat resistant, water proof, stable at high temperature;

• environmentally friendly,no smell and not-toxic;

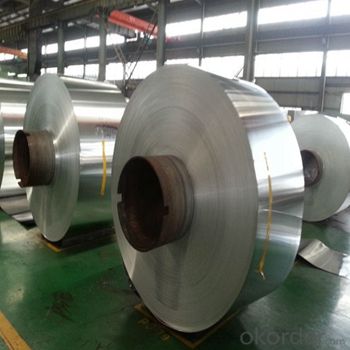

3.Aluminum Foil Facing Images

4.Aluminum Foil Facing Specification

TYPICAL PHYSICAL PROPERTIES:

PROPERTIES | UNIT | VALUE | TEST METHOD |

Basic weight | gsm | 80 | ASTM D646 |

Tensile strength: M. D. X. D. | N/25mm | 95 50 | ASTM C1136 |

Burst strength | N | 25 | ASTM D774 |

Reflectivity of foil surface | % | 95 | ---------- |

Temp. Resistance | -29°C +66°C | No change keep soft | ASTM C1263 |

Water vapor permeance | ng/N.s | 1.15 | ASTM E-96 |

Water Soak Test | 24hrs | No delamination | ---------- |

Width: 1.0m, 1.2m, 1.25 m, 1.30, 1.37m

Length: 200m, 500m, 1000m, 2500m, 2750m, 3300m

Core I.D.: 3"(76mm ±1), 72mm ±1

Based on order, special sizes are also available.

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

(1) How about your company?

A world class manufacturer & supplier of aluminum foil facing and is one of the large-scale professional investment aluminum foil facing bases in China. Annually more than 1000 containers of aluminum foil facing are exported to markets in Europe, America and Japan.

(2)What is the storage condition?

The products should be stored at room temperature and kept from wet and heat source.

It is essential, as with all pressure-sensitive tapes, that the surface to which the tape is applied must be clean, dry, and free of grease and oil.

The user should take test and do trial-application on the above products before coming into application so as to witness and ensure suitability for user’s special purpose and technique.

(3) How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q: Considerations for hand held aluminium foil sealing machine

- Should the white glue boards often view the inductive head in front of the color, if there are serious undo charred discoloration, inductive head rib cover to check, whether the induction coil insulation paint carbonization or fall off, if this phenomenon should be replaced or induction coil induction head in a timely manner, so as not to damage the host to continue to use.

- Q: The working principle and characteristics of hand held aluminum foil sealing machine

- The machine can be divided into two parts: the control box and the output induction head. 100KHZ high frequency current generated by the microcomputer control source by amplifying, shaping, push the power module output to the sensor head, when the metal aluminum foil container Gary proximity sensing head, eddy current heating on the aluminum foil, heating degree by the intensity and duration of the short length to determine eddy current. The whole machine is equipped with an automatic frequency stabilizing circuit, the function time can be adjusted and the working status can be displayed. This machine has been improved to slow the sealing speed of the 500A model, so that the machine can be continuously heated by heating without stopping once. Therefore, the sealing speed of the machine is much faster than that of the 500A model.

- Q: What is the difference between metallized capacitor and metal film capacitor?

- Aluminum electrolytic capacitor common aluminum electrolytic capacitor, it is made of aluminum cylinder, which contains liquid electrolyte, made of a layer of aluminum foil, a layer of insulation coil. Or through the DC voltage treatment, the pole of the film on the formation of an oxide film as a medium. The utility model has the advantages of large capacity, large leakage, poor stability, positive and negative polarity, and is suitable for power supply filtering or low frequency circuits. When using, the positive and negative electrodes do not connect with the reverse.

- Q: Must there be foil wrapper in the Tea Caddy?

- This is usually to keep dry, and if the tea itself has been wrapped up in vacuum, then there is no need

- Q: What are the application areas of aluminum foil?

- Is the use of flexible packaging bag type container made of soft composite packaging materials, soft packaging has greatly improved the level of mechanization and automation of the food and beverage industry, accelerate the modernization and socialization of people's diet life. In developed countries, soft packaging has become one of the main packaging forms of food and beverages, and has replaced cans and bottles in a certain range. In recent years, China's packaging market development is also very fast, has introduced a 10 aluminum foil production line, according to the different purposes of the soft packing dry composite, composite, hot melt extrusion composite technology etc.. Flexible packaging not only has the function of moisture-proof and preservation, but also can print various patterns and characters. It is the ideal material for modern commercial packaging. With the improvement of people's living standard, there is still a lot of room for the development of flexible packaging aluminum foil.

- Q: What are the specifications and uses of common aluminum foil?

- Aseptic packageAlloy status: 1235-O, 8111-O, 8079-OTypical thickness: 0.0063, 0.00635Processing methods: aluminum composite paper, printingEnd use: barrier material with (drinking soda straw) Straw hole rectangular carton packaging, such as Tetra Pak, Combibloc etc..

- Q: Aluminum foil lunch box microwave oven operation method?

- That depends on what kind of aluminum foil lunch box, coated with, for example, rainbow aluminum foil lunch box.Specific use: be sure to open the lid, food should not be too full, placed in the middle of the microwave oven.Hope to adopt, thank you!

- Q: Is the quality of aluminium foil lunch box good? It looks good. Ha, it looks pretty tall. I don't know if it's reliable

- Really haven't seen, general take away boxes are transparent plastic, feel first is not green, second will be toxic

- Q: Pan middle foil cake is not able to stick?

- Covered with tinfoil will stick. The foil is coated with a layer of butter on it

- Q: Dcgy-500 type aluminum foil sealing machine is out of order, it is not sealed, burned out which element, how to fix?

- Hand held aluminum foil sealing machine operation method:The container with aluminum foil sealing machine alignment sensor head center (previously placed induction aluminum foil container cover and tighten the membrane compaction) click on the handle "induction switch", then the original set time countdown to zero, said the work has been completed, and then remove the head of a container under induction a sealing operation.Check the sealing quality, according to different materials, diameter containers, and production efficiency, and properly trim the "time setting button", so that the sealing quality to the best.

Send your message to us

Aluminium Foil Mylar Tape For Cable Shielding from CNBM

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 300 kg

- Supply Capability:

- 400000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords