15/32 Film Faced Plywood - High Quality Top Sale

- Loading Port:

- Lianyungang

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m³

- Supply Capability:

- 20000 m³/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Specifications

1.size:1220*2440*1.7-35mm

2.surface:veneer,PVC,PU,UV,Melamine paper

3.material:poplar hardwood combi

4.usage:furniture,packing,construction

Good quality Commercial Plywood

Brief Introduction:

Hardboard density is plant fiber as raw materials, processed into density greater than 0.8g/cm of fiberboard, high strength, good workability easy bend, tenon and punch.

According to the panel is divided into one face light hardboard and both face light hardboard.

Structure of products Description:

Plain fiber hard board is made from fresh wood fibre and enviromental glue. We usually use poplar wood, pine wood, eucalyptus wood and other hard wood as raw material to make MDF

board.The thickness of board is from 2mm to 6mm. Standard size of plain MDF is 1220x2440mm. Density from 850m3 to 950kgs/m3. production from Diffenbacher Germany. Surface is very smoothly and density curve is perfect. Low emission of formaldehyde and High density fiber board

Packaging Detail: Loose packing or pallets

Delivery Detail: 14 days after deposit

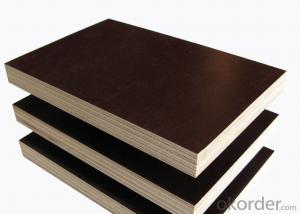

Specifications of hardboard:

1)Size: 1220*2440*2.5mm~6mm

2)Glue: E0,E1

3)Tolerance of Thickness: +/-0.2mm

4)Material: Poplar and Mix Wood

5)Color: Brown or Dark Brown

6)Density: 950kg/m3~1000kg/m3

7)Face and Back: Smooth and Mesh Pattern

8)Moisture Content: 4%~8%

9)Certificate: ISO9001:2000SGS

10)Bending Strength:33~48Mpa

11)Usage: The Trim of Car,Package,Furniture,Sofa Inside,Photo Frame Back,Baby Carrier,Crib decoration panel and so on

Image:

- Q: The difference between the multilayer board and the plywood is as follows

- Commonly used plywood, plywood and other multi-layer board. Multilayer boards can improve wood utilization and are a major way to save wood

- Q: Now what is the market for plywood development?

- has also been greatly improved in the international market more and more competitive. China is not only a large veneer export, or the world's largest plywood producer.

- Q: How to use building plywood?

- in the decoration works mainly used in ceilings, wall skirts, floor linings and so on.

- Q: Plywood can improve timber utilization and is a major way to save wood.

- Also available for aircraft, ships, trains, cars, construction and crates and other materials.

- Q: How is the current market outlook for plywood?

- Although China plywood has developed rapidly, but still encounter the EU and other importing countries of the anti-dumping complaints

- Q: A brief introduction to plywood

- The number of layers is generally odd, and few are even. Vertical and horizontal direction of the physical and mechanical properties of small differences

- Q: What is the difference between plywood glue E0E1?

- Urea-formaldehyde glue: moisture-proof glue / for interior decoration, furniture, can not be used for outdoor.

- Q: Why is the plywood commonly used in the singular layer

- and the back of the stripes) from the beautiful and do not look good

- Q: Solid wood and plywood which is better?

- the difference between selection: multi-layer solid wood flooring due to take into account the different species of "alternative heterosexual", so that the production process can fully balance the "internal stress"

- Q: The usual length and width specifications are:

- The main tree species are: camphor, willow, poplar, eucalyptus and so on. The main origin of plywood: Indonesia and Malaysia.

Send your message to us

15/32 Film Faced Plywood - High Quality Top Sale

- Loading Port:

- Lianyungang

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m³

- Supply Capability:

- 20000 m³/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords