Deformed Steel Bar 8mm 16mm 18mm 20mm 22mm 10mm

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 150 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

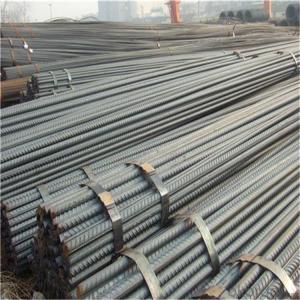

Deformed Steel Bar 8mm 16mm 18mm 20mm 22mm 10mm

Description of deformed steel bar 8mm 16mm 18mm 20mm 22mm 10mm

1, Diameter: 5.5mm-10mm deformed steel bar 8mm 16mm 18mm 20mm 22mm 10mm

10m- 40mm deformed steel bar 8mm 16mm 18mm 20mm 22mm 10mm

2, Length: 6m, 9m, 12m or customized

3, Standard: GB, ASTM, AISI, SAE, DIN, JIS, EN

OEM technology - send detailed technical parameters for accurate quotation.

2, Produce Process: smelt iron - EAF smelt billet - ESR smelt billet -

hot rolled or forged to get the steel round bar and plate

3, Heat Treatment: annealing, normalizing, tempering, quenching

4, Surface Treatment: Black

5, Quality Assurance: We accept third party inspection for all orders.

You can ask testing organizations such as SGS, BV, etc. to test our products before shipping.

Chemical Composition of deformed steel bar 8mm 16mm 18mm 20mm 22mm 10mm

Grade | Technical data of the original chemical composition(%) | |||||

Reinforcing steel bar HRB335 | C | Mn | Si | S | P | B |

≤0.25 | ≤1.60 | ≤0.80 | ≤0.045 | ≤0.045 | >0.0008 | |

Physics Capability | ||||||

Yield Strength(N/cm2) | Tensile Strength(N/cm2) | Elongation(%) | ||||

≥ 335 | ≥490 | ≥16 | ||||

Reinforcing steel bar HRB400 | C | Mn | Si | S | P | B |

≤0.25 | ≤0.16 | ≤0.80 | ≤0.045 | ≤0.045 | 0.04-0.12 | |

Physics Capability | ||||||

Yield Strength(N/cm2) | Tensile Strength(N/cm2) | Elongation(%) | ||||

≥ 400 | ≥ 570 | ≥ 14 | ||||

Products Show of deformed steel bar 8mm 16mm 18mm 20mm 22mm 10mm

Company Information

CNBM International Corporation is the most important trading platform of CNBM group.

Whith its advantages, CNBM International are mainly concentrate on Cement, Glass, Iron and Steel, Ceramics industries and devotes herself for supplying high qulity series of refractories as well as technical consultancies and logistics solutions.

F A Q

1, Your advantages?

professional products inquiry, products knowledge train (for agents), smooth goods delivery, excellent customer solution proposale

2, Test & Certificate?

SGS test is available, customer inspection before shipping is welcome, third party inspection is no problem

3, Factory or Trading Company?

CNBM is a trading company but we have so many protocol factories and CNBM works as a trading department of these factories. Also CNBM is the holding company of many factories.

4, Payment Terms?

30% TT as deposit and 70% before delivery.

Irrevocable L/C at sight.

5, Trading Terms?

EXW, FOB, CIF, FFR, CNF

6, After-sale Service?

CNBM provides the services and support you need for every step of our cooperation. We're the business partner you can trust.

For any problem, please kindly contact us at any your convenient time.

We'll reply you in our first priority within 24 hours.

- Q: How does heat treatment affect the properties of special steel?

- Heat treatment can significantly impact the properties of special steel. By subjecting the steel to controlled heating and cooling processes, its mechanical properties can be modified. For instance, heat treatment can enhance the steel's hardness, strength, and toughness, making it more suitable for specific applications. Additionally, heat treatment can alter the steel's microstructure, such as grain size and distribution, thereby affecting its corrosion resistance and overall performance. Overall, heat treatment plays a crucial role in tailoring the properties of special steel to meet desired requirements.

- Q: How does special steel contribute to the oil and gas machinery industry?

- The oil and gas machinery industry heavily relies on special steel due to its wide range of essential properties and characteristics. Its exceptional strength and durability allow it to withstand the extreme forces and pressures involved in oil and gas extraction, transportation, and refining processes. This ensures reliable and efficient machinery operation, minimizing downtime and maintenance costs. Special steel also possesses excellent corrosion resistance, which is crucial in an industry where equipment is constantly exposed to corrosive environments like seawater, acidic gases, and high-temperature fluids. Using corrosion-resistant special steel increases machinery lifespan, reduces equipment failure risk, and enhances overall safety. Moreover, special steel exhibits high temperature resistance, which is vital in this industry where equipment operates at extremely high temperatures, especially in drilling, refining, and petrochemical production processes. Special steel alloys maintain their structural integrity under these elevated temperatures, ensuring safe and efficient machinery functioning. Additionally, special steel offers exceptional wear and abrasion resistance properties, making it ideal for components exposed to constant friction such as valves, pumps, and drilling tools. This wear and abrasion resistance prolongs component lifespan, reduces maintenance needs, and enhances overall machinery efficiency. In summary, special steel significantly contributes to the oil and gas machinery industry by providing the necessary strength, durability, corrosion resistance, high temperature resistance, and wear resistance required for demanding operating conditions. By utilizing special steel alloys, manufacturers can create robust and reliable machinery capable of withstanding the challenges of the oil and gas industry, ensuring the smooth and safe extraction, transportation, and processing of oil and gas resources.

- Q: What are the environmental considerations of using special steel?

- Special steel production has significant environmental considerations. The extraction and processing of raw materials, such as iron and coal, contribute to deforestation, habitat destruction, and greenhouse gas emissions. Moreover, the high energy requirements during steel production result in carbon dioxide emissions, contributing to climate change. Special steel also often requires the use of alloying elements, such as chromium and nickel, which can lead to toxic waste and pollution if not properly managed. Therefore, careful monitoring and implementation of sustainable practices are crucial to minimize the environmental impact associated with using special steel.

- Q: How is special steel used in the production of aircraft landing gear?

- Due to its outstanding mechanical properties and durability, special steel is extensively utilized in the manufacturing of aircraft landing gear. The landing gear, a critical component responsible for supporting the weight of an aircraft during takeoff, landing, and ground operations, must endure tremendous forces, impact loads, and harsh environmental conditions. Special steel, including high-strength low-alloy (HSLA) steel or alloy steel, is carefully chosen for its remarkable strength-to-weight ratio, high resistance to fatigue, and excellent ability to resist corrosion. These characteristics are essential in ensuring that the landing gear can withstand the extreme forces and stresses encountered during aircraft operations. The utilization of special steel in the production of landing gear offers multiple advantages. Firstly, it enables the landing gear to be lighter in weight, contributing to an overall reduction in the aircraft's weight. This results in improved fuel efficiency and increased capacity for carrying cargo, which are crucial factors in enhancing the performance of modern aircraft and reducing operating costs. Secondly, the high fatigue resistance of special steel ensures that the landing gear can endure repeated loading cycles without experiencing significant degradation in performance. This is of utmost importance since the landing gear is subjected to substantial stress during each landing and takeoff. It must be capable of withstanding these forces over a long operational lifespan. Furthermore, the excellent corrosion resistance properties of special steel guarantee that the landing gear remains protected from environmental elements such as moisture, salt, and other corrosive substances. Corrosion can weaken the structure of the landing gear, compromising its integrity and safety. Therefore, the use of special steel helps to ensure the longevity and reliability of the landing gear, reducing the need for maintenance and associated costs. To summarize, special steel plays a vital role in the manufacturing of aircraft landing gear due to its exceptional strength, fatigue resistance, and corrosion resistance. Its incorporation allows for the production of lighter and more durable landing gear, resulting in improved aircraft performance, enhanced efficiency, and increased safety.

- Q: How is wear-resistant steel used in mining and earthmoving equipment?

- Wear-resistant steel is used in mining and earthmoving equipment to enhance their durability and longevity in harsh operating conditions. It is utilized to manufacture various components such as buckets, blades, cutting edges, and wear plates that are constantly subjected to abrasion, impact, and high stress. These steel parts ensure the equipment can withstand the abrasive nature of rocks, minerals, and other materials encountered during mining and earthmoving operations, reducing maintenance needs and increasing productivity.

- Q: Can special steel be used in high-pressure applications?

- Yes, special steel can indeed be used in high-pressure applications. Special steels, also known as alloy steels, are specifically designed to have enhanced mechanical properties such as high strength, ductility, and corrosion resistance. These properties make them suitable for withstanding high-pressure environments. Special steels are commonly used in industries such as oil and gas, aerospace, automotive, and power generation, where high-pressure applications are encountered. For example, in the oil and gas industry, special steels are used to manufacture high-pressure pipelines, valves, and pressure vessels that can withstand the extreme pressure conditions during oil drilling, transportation, and refining processes. The high strength of special steel allows it to withstand the internal pressure exerted by fluids or gases without deformation or failure. Additionally, its corrosion resistance properties ensure that the steel remains intact and free from damage caused by the harsh operating conditions often associated with high-pressure applications. Moreover, special steels can be tailored to meet specific requirements by adjusting their chemical composition and heat treatment processes. This customization allows the steel to exhibit even higher strength, toughness, and resistance to fatigue, making it ideal for applications involving high-pressure environments. In summary, special steel can be used in high-pressure applications due to its enhanced mechanical properties and corrosion resistance. Its ability to withstand extreme pressures makes it a reliable choice for various industries where high-pressure conditions are encountered.

- Q: What are the different tempering techniques used for special steel?

- There are several tempering techniques used for special steel, including air tempering, oil tempering, water tempering, and salt bath tempering. Each technique involves heating the steel to a specific temperature and then cooling it at a controlled rate to achieve desired hardness, strength, and other mechanical properties.

- Q: How does special steel contribute to the manufacturing aftermarket industry?

- Special steel plays a significant role in the manufacturing aftermarket industry by offering enhanced performance, durability, and reliability in the production of various components and equipment. One of the key contributions of special steel is its ability to withstand extreme conditions, such as high temperatures, corrosive environments, or heavy loads. This makes it an ideal material for manufacturing critical parts used in industries like automotive, aerospace, energy, and machinery. In the manufacturing aftermarket industry, special steel is commonly used in the production of replacement parts for machinery or equipment that have become worn out or damaged over time. The use of special steel ensures that these replacement parts possess the necessary strength and resilience to meet the original equipment manufacturer (OEM) specifications. Furthermore, special steel allows for the development of innovative designs and the production of more efficient and lightweight components. This helps in improving the overall performance of the equipment, reducing energy consumption, and enhancing productivity. For example, in the automotive industry, special steel is used to manufacture lightweight engine components, resulting in improved fuel efficiency and reduced emissions. Moreover, the use of special steel in the manufacturing aftermarket industry contributes to the reduction of maintenance and downtime costs. By using high-quality steel, the longevity of the replacement parts is increased, reducing the frequency of repairs or replacements. This leads to a decrease in production downtime and associated costs, as well as improving the overall reliability of the equipment. Additionally, special steel offers a wide range of customization options, enabling manufacturers to tailor the material properties to specific requirements. This flexibility allows for the development of unique solutions and the production of specialized components that meet the demands of various industries. It also enables manufacturers to address specific challenges related to wear resistance, hardness, or toughness, which are crucial factors in the aftermarket industry. In conclusion, special steel contributes significantly to the manufacturing aftermarket industry by providing enhanced performance, durability, and reliability to replacement parts. Its ability to withstand extreme conditions, enable innovative designs, reduce maintenance costs, and offer customization options makes it an indispensable material in the production of components and equipment in various industries.

- Q: What are the different methods for shot peening special steel?

- There are several methods for shot peening special steel, including air blast peening, wheel blast peening, and centrifugal peening. Air blast peening involves directing a stream of shot particles onto the surface using compressed air, while wheel blast peening uses a rotating wheel to propel the shot particles. Centrifugal peening utilizes a spinning wheel to throw the shot particles onto the steel surface. Each method has its own advantages and is used based on the specific requirements of the steel and the desired outcome of the shot peening process.

- Q: What are the properties of copper alloys?

- Copper alloys have various properties such as high electrical and thermal conductivity, excellent corrosion resistance, good strength and ductility, as well as a pleasing aesthetic appearance. They are also known for their antimicrobial properties and are commonly used in electrical wiring, plumbing systems, and various industrial applications.

Send your message to us

Deformed Steel Bar 8mm 16mm 18mm 20mm 22mm 10mm

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 150 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords