Cryogenic Insulation Paper with Aluminum Foil Surface

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

The fire retardation glass fiber Cryogenic & Insulation paper is made of superfine glass fiber with special processing. This is usually used with aluminium foil and used for transport containers which store liquid helium, liquid hydrogen, liquid nitrogen,LNG etc.

The superfine glass fiber Cryogenic & Insulation paper's diameter between 0.1-0.6μm and fiber glass filament (diameter between 3-5 μm). According to a certain proportion, the paper is produced under the wet & vacuum forming process to make the paper have the space lattice structure. All the glass fiber is inorganic material, so it has outstanding flame retardant properties. Specifically engineered for use at big temperature range (approaching -273℃—500℃) and also the paper is really stable in the low temperature condition.

Cryogenic Insulation Paper Features:

The main way of heat conduction is by radiation heat exchange in the low and vacuum condition. In order to reduce the radiation heat exchange to meet the good heat insulation effect, by using aluminum foil for reflecting screen and superfine glass fiber insulation paper for spacer, then the multilayer combination of aluminum foil reflective screen and cryogenic & insulation material can build up the efficient thermal barrier against heat transfer in insulated vacuum storage containers. This material can be freely winding, and help the user to reduce the waste of manpower and material waste.

Cryogenic Insulation Paper Application:

Cryogenic liquid (liquid helium, liquid hydrogen, LNG, liquid oxygen, liquid nitrogen, liquid argon, etc.)

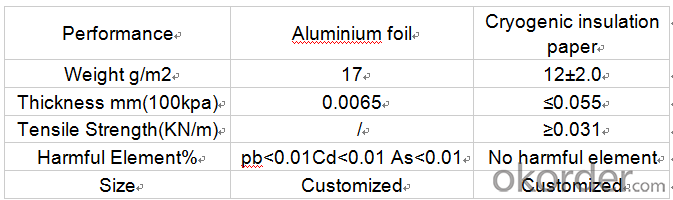

Cryogenic Insulation Paper Specifications

1.light weight

2.good uniformity

3.low thermal conductivity

Technical data:

Q1 What’s the transport method?

A1 FCL delivery goods with wooden pallet; If LCL delivery, must with wooden case; Sometimes need open top, flat rack or bulk cargo.

Q2 What’s the required payment term?

A2 Generally 30% TT as the prepayment, 70% TT before delivery. If need, 100% Irrevocable Letter of Credit or negotiation.

Q3 Which country are our products exported to?

A3 Apart from entire Chinese market, the US, Russia, Japan, Korea, Australia and some Southeast Asian Nations.

- Q: How can there be a low temperature cabinet in Hangzhou

- Do low-temperature freezers to do the manufacturers or less, or you can look at Haier's. Cold snow is also doing this low temperature freezer!

- Q: Chapter 6 of the management and use of large medical equipment

- Health Bureau: According to the "large-scale medical equipment configuration and use of management approach" (Wei Zhengfa Fa [2004] No. 474) provides that the third batch of large-scale medical equipment management items are announced. Please strictly in accordance with the provisions of large-scale medical equipment management, conscientiously implement the system, and further do a good job in large-scale medical equipment configuration, use and centralized procurement management. January 17, 2013 annex: A large medical equipment management items (third batch) First, the positron emission magnetic resonance imaging system (English referred to as PET-MR, including the integration and split two types) Second, TrueBeam, TrueBeam STX Medical Linear Accelerator Third, Axesse type medical linear accelerator

- Q: What aspects of low temperature plasma equipment can be used?

- textile, plastic products, automobile manufacturing, electronic equipment manufacturing, home appliances manufacturing, computers, mobile phones, Medical equipment, oil and gas pipelines, heating pipes, electronic circuits and plasma diodes, magnetic recording materials and optical waveguide materials, special ceramics (including superconducting materials), lighting and display, welding, fine processing

- Q: Minus 40 degrees of medical cryocell how to operate

- and low temperature test The interior of the box has a fan that circulates the air at all times, so the cooling is relatively uniform and the temperature is straight

- Q: What are the medical sterilization methods?

- Medical equipment used in the operating room generally does not leave the sterilization environment; if necessary, the use of sterilization equipment cover (one or more high-temperature sterilization cloth cover) will cover the equipment;

- Q: but also have better shock performance and anti-extrusion performance, according to the above requirements, the election 20 Medical refrigerated box requirements can be a long time to keep low temperature, dry, but also have better shock resistance and anti-extrusion performance, according to the above requirements, select the best material. (1) the production of cold storage box shell, should be used Cotton Foam Plastic Hardboard (2) cold storage box cooling filler material, should be used Crushed ice cubes low temperature brine foam dry ice (3) cold box inside the shell close to the liner, should be used Soft paper velvet foam leather

- Hard plastic plate, dry ice, foam shell requirements anti-extrusion, only hard plastic plate to meet the requirements.

- Q: Ultra-low temperature refrigerator, medical refrigerator which brand of good

- Refrigerators are actually the same, the general abrasive has a, each other Chuanhuo, find the real manufacturers, cheap, and quality assurance

- Q: Refinery low-temperature equipment which, high-temperature equipment which?

- This problem is not good to answer, with a different device in different devices may become a low-temperature equipment, may become a high-temperature equipment

- Q: Medical low temperature refrigerator PQ (performance confirmation) has no one done!

- According to the provisions of the medical refrigerator applicable to the national standard,

- Q: What is the medical cleaning device? What should I consider? Solution

- 3, reverse osmosis and EDI system portfolio editor Process: raw water → raw water pressurized pump → multi-media filter → activated carbon filter → water softener → precision filter → a reverse osmosis machine → intermediate water tank → intermediate water pump → EDI system → purified water tank → pure water pump → UV disinfection → Microporous filter → water point This process uses reverse osmosis and EDI system as the core of ultra-pure water equipment, which is the most advanced ultra-pure water preparation process, not only environmental protection and energy saving, and stable performance, excellent water quality. However, the investment cost of this device is relatively high. More than three kinds of technology, have their own advantages and disadvantages; believe that the choice of equipment in various hospitals will be based on the actual situation to choose the most suitable for hospital development of medical equipment cleaning equipment.

Send your message to us

Cryogenic Insulation Paper with Aluminum Foil Surface

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords