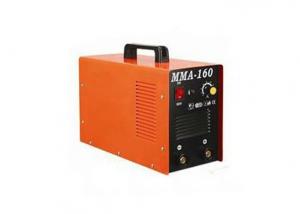

CO2 MIG MAG Gas Shielded Double Drive Welding Wire Feeder

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 200 unit/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Key Attributes

Product Model | Double drive wire feeder |

Rated Input Voltage | DC18.3V / DC24V |

Rated Input Current | 5A |

Welding Current | 400A/100% 500A/60% |

Wire Diameter | 1.0/1.2/1.6mm |

Wire Feed Rate | 1.5-20m/min |

Applicable Wire Reels | Φ300Xφ50X103 |

Maximum Capacity | 20KG |

Protection Level | IP2X |

Type | Panasonic |

Packaging

Package | Carton |

Single package size | 1250pxx750pxx750px |

Single gross weight | 10 kg |

- Q: What brand of MAG/MIG welding machine good stability high load rate (the main processing non-ferrous metals such as copper and aluminum) and the teacher requested to introduce.

- This depends on the actual situation of your company, depending on how much money you intend to buy. I used the equipment has Sweden ESAB, France SAF, Japan OTC, are very good, domestic also write, but the performance is good is not too much! You can choose a few brands by comparison!

- Q: What are the principles of Tandem twin wire welding and monofilament composite pulsed MIG welding?

- Tandem double wire welding is to place two welding wires at a certain angle in a specially designed welding torch, and two welding wires are respectively supplied by independent power supply. In addition to feeding speed can be different, other parameters, such as: wire material, diameter, pulse, etc. can be set independently of each other, so as to ensure the arc work in the best state. Compared with other twin wire welding technology, the welding efficiency and welding speed are improved because the arc of two welding wires is burned in the same molten pool and the total welding current is increased. At the same time, because the two welding wires are sent to the same molten pool alternately, the mixing action of the welding pool is reduced, and the sensitivity of the porosity is improved, and the quality of the weld is improved.

- Q: MIG automatic welding is always broken arc is how ah?

- There are several reasons for arcing:First, the power load capacity is poor.1, power line is too long, too small;2, the power supply voltage is too low, two, welding machine itself problems1, secondary current adjustment is too small, and the diameter of the welding rod does not match.2, each node serious corrosion, bad contact.Three. Welding rod quality problem.1, welding rod itself quality is slightly lower,2, welding rod damp, medicine skin deterioration or failure.

- Q: The difference between TIG welding and MIG welding

- TIG is a non melting electrode TIG welding, is a manual electric arc welding with argon gas protection, while MIG belongs to inert gas welding consumable electrode, and the TIG is different to manual wire for automatic wire feeding.

- Q: Which is better, TIG welding method and MIG welding method?

- The former is suitable for welding thin plate, which is suitable for heavy plate and mass production. In many aspects, TIG welding is less limited.

- Q: The difference between MAG welding machine and MIG welding machine

- MIG:Metal Inert Gas welding, MIG welding, argon gas, helium (Ar) (He) or a mixed gas, do not react with liquid metal, only isolated from the air, so stable arc combustion, droplet transition smooth, stable, no fierce splash, the most suitable for welding of aluminum, copper, titanium and other non-ferrous metals, can also be used for steel, such as stainless steel, heat-resistant steel welding etc.;MAG:Metal Active Gas welding, metal active gas welding, gas by inert gas and a small amount of oxidizing gases (O2, CO2 or a mixed gas) mixture, without changing or basically does not change the inert gas arc characteristics under the condition of improving arc stability, improve the forming and reduce the radiation intensity of arc weld, welding used in black metal materials.

Send your message to us

CO2 MIG MAG Gas Shielded Double Drive Welding Wire Feeder

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 200 unit/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products