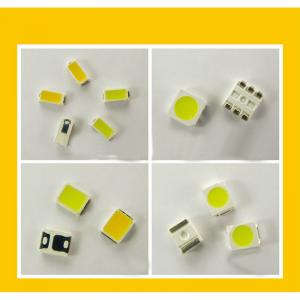

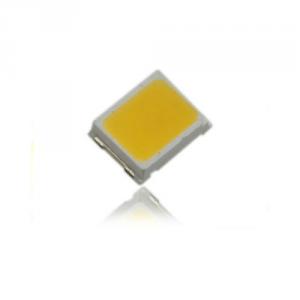

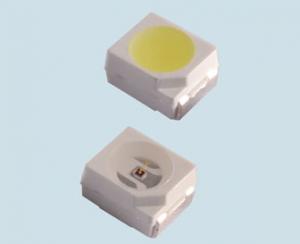

China Factory Hot Selling SMD LED Diodes

- Loading Port:

- Shenzhen

- Payment Terms:

- L/C,T/T

- Min Order Qty:

- 1000 Pcs pc

- Supply Capability:

- 100000 Pcs Per Month pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

smd led diodes Specifications:

1 chip material: inGaN/GaAsp

2 Shap:round led,oval led, straww halt led, square led,flat top led,bullet led,concave led,rectangle led

3 Avilable size: 2mm,3mm,5mm,8mm,10mm,20mm

4 Lens type: water clear,color transparent,colored diffuse

5 Emitted color; ,White,

6 Different angle availible

7 low power consumption,high intensity,uniform illumination

8 solid-state;high shock and viberation resistent

9 Major reduction in power cost

10.No RF interference

11 Maintenance free easy installation

12 superior ESD protection

Application:

1. Indoor and outdoor commercial lighting

2. Architectural Lighting

3. General lighting

4. Automotive lights

5. Mood Lighting, LED module

6. Traffic Light

7. LCD TV / monitor backlights

8. LED display

9. Reading light, LED torch

10. Craft flashlights, headlights

Delivery:

Shipping Service | Estimated Delivery Time |

DHL | 2-8 business days |

FedEx | 3-8 business days |

TNT | 2-10 business days |

UPS | 1-7 business days |

EMS | 6-14 business days |

ePacket | 7-12 business days |

China Post Air Mail | 7-15 business days |

China Post SAL | 14-30 business days |

By sea | 30-40 business days |

1. 3-10 business days for Sample Orders; 7-40 business days for Bulk Orders.

2. "Business days" means Monday-Friday, excluding holidays.

3. DHL and UPS cannot ship to military or P.O. boxes address.

4. The Shipping Service above is for reference only, for any other questions, please feel free to contact us.

Our service

1.your inquiry related to our products or prices will be replied in 24hours.

2.well-trained and experienced staffs to answer all your enquires in fluent English

3.OEM and ODM,any your custonized lightings we can help you desiign put into product

4.Distributonership are offered for your unique design and some our current models

5.protection of your sales area,ideas of design and all your private information

About Us

We manufacture a wide range of optoelectronic components and deliver them to markets in Europe and North America. We offer DIP LEDs, SMD LEDs, high-power LEDs, flexible/rigid LED strips, spotlights, bulbs, downlights, modules and LED tubes. Our products are used in the fields of indication, decoration, outdoor/indoor lighting and more. All of our LED products carry CE and RoHS certifications.

If you need custom samples, our R&D experts can have one ready in three weeks. At our ISO 9001:2000-certified factory, we conduct strict QC procedures to ensure each unit is up to your quality standard. Every month, we turn out 30 million LED lamps, 10 million SMDs, 500,000 High Power LEDs, 400,000meters LED strips, 20,000 LED spotlights and downlights and 10,000 LED tubes. Usually, we can complete your orders in seven days.

We are experienced in providing professional services to big buyers both domestic and oversea market.

- Q: What is the principle used in SMD LED lamp, should pay attention to what the problem?

- LED installation method 1, don't install the LED pin in 2, under the condition of deformation in printed circuit board when installing LED, circuit board hole center distance and LED pin center spacing should be the same, if the hole spacing will make the lamp feet have residual stress and welding...

- Q: What is the difference between SMT LED packaging with silicone and epoxy resin transparent package? What is the market situation of these two types of packaging?

- The main difference is the encapsulation method. The liquid silicone is mainly encapsulated and encapsulated, while the gum cake is solid and adopts a transfer molding package. Of course, there is a fundamental difference between the material, silica gel can be used for white light high-power LED, suitable for lighting. The epoxy can only be used in low-power monochrome LED, suitable for display, backlight, induction and other components.

- Q: Indoor full color LED display module and LED what is the difference between a full color?

- (1): LED full color light emitting module display module is generally yellow green, pure green module price is more expensive; SMD full color LED display using pure green tube coreThe display module (2): LED full color pixel visual feeling is thick, low brightness, easy to have the mosaic phenomenon; patch LED full color consistent, high brightness;(3): maintenance module LED full color display is not easy to maintain, the whole module replacement cost is high; SMD full-color LED screen for easy maintenance, repair and replacement of single lamp;

- Q: LED light SMD LED package in what form, trouble you under the guidance of...

- Draw your own line, mm is replaced by mil on the line, with vernier caliper measurement, or know the model, count the number of mil. For example, 5050 is a close square with a width of 5.0mm*5.0mmInline LED (such as straw hat lights, 5mm), piranha LED, surface mount LEDSinglechip collection from hardware to software chm

- Q: What is the difference between patch LED beads and LED beads: General

- Patch is a LED lamp, 0805, SMD beads 3014, 3528, 2835, 5050, 5630, 5730 and so on.

- Q: Does anyone know what the current rating of a white high brightness LED patch is? Where can I find out?

- LED high power and low power, small white rated current and LED wafer, such as a chip is 20MA two 40MA.... High power 0.5W, 100-150MA, 1W, 350MA current rating in the relevant product specifications

- Q: What is the difference in performance between the LED plug-in and the LED patch?

- No difference, because the core of the two is the same, are diode PN junction, but no packaging, the production process is a little different

- Q: LED package and LED SMD LED lamp, what is the difference? Will the release agent be used in that part?

- Mold release agent is a functional substance between the mold and the finished product. The release agent is chemically resistant and is not soluble in contact with the chemical constituents of different resins (especially styrene and amines). Release agent also has heat and stress properties, not easy to decompose or wear; release agent bonded to the mold, and not transferred to the processed parts, without prejudice to painting or other two processing operations. Because of the rapid development of injection molding, extrusion, calendering, molding and laminating, the dosage of mould release agent is greatly improved.

- Q: How do led patches measure good or bad?

- The patch LED is also called SMD LED. Its principle of luminescence is to pass the current through the compound semiconductor. Through the combination of the electron and the hole, the excess energy will be released in the form of light to achieve the effect of luminescence.

- Q: Such as title, please have welding patch LED lamp experience expert guidance, do not search from the Internet to the theoretical knowledge, thank you!

- When soldering, the temperature is best to be lower, and the average welding temperature is about 360. That's enough, because the melting temperature of the tin wire is about 220 degrees, so if it is allowed, the temperature can be reduced as low as possible.

Send your message to us

China Factory Hot Selling SMD LED Diodes

- Loading Port:

- Shenzhen

- Payment Terms:

- L/C,T/T

- Min Order Qty:

- 1000 Pcs pc

- Supply Capability:

- 100000 Pcs Per Month pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches