CE Approved Construction Hoist, Construction Site Elevator (SC200/200)

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 1000 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Structure of Building Hoist

Model NO.:

Type:

Application:

Tower Crane Type:

Sling Type:

Main Girder Form:

Power Source:

Moving Type:

Installation:

Certification:

Condition:

Max.Lifing Load:

Max.Lifting Height:

Main Power Source:

Cage Size:

Cage:

Mast of Section:

Color:

Warranty:

Total Power:

Max. Free End Height of Guides:

Export Markets:

Building hoist Specifiction

| m/min | 0-96 | ||

| Free standing height | m | 50 | |

| Max. Lifting Height | m | 400 | |

| Max. Free End Height of Guides | m | 7.5 | |

| Modulus | 8 | ||

| Carriage Weight | kg | 1012×2 | |

| Size of Carriage | m | 3×1.3×2.3 | |

| Standard Knot Weight | kg | 146 | |

| Dimension of mast section | m | 0.65×0.65×1.508 | |

| Motor | |||

| Rated Power | Kw | 3×18.5 | |

| Rated Rotate Speed | r/min | 1460 | |

| Reducer | Center Distance | mm | 125 |

| Ratio | 1:16 | ||

| Over speed Governor | Type | progressive type | |

| Model | SAJ40-1.2A safety device | ||

| Operation Speed | m/min | 51.6 | |

| Brake Moment | N.m | ≥3000 | |

| Lifter Weight | t | 22 | |

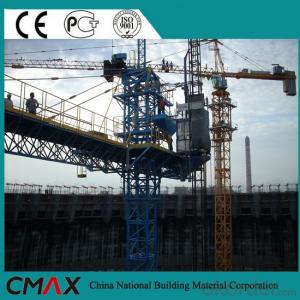

Building Hoist Images

FAQ of Building Hoist

Q: What is the building hoist main purpose?

A: Building hoist equipped with double or single cabin to transport the materials and labors up and down. It's the ideal

construction equipment for vertical transportation in the field of construction.

Q: What is the main structure of building hoist?

A: The P/M construction hoist mainly contains metal structure, driving system, electrical control system, cable guide &

protection system, electrical top crane and safety device.

Q: What is the meaning of the building hoist’s code?

A: Take SC200/200 for example: “SC” stands for rack and pinion hoist, “200/200” stands for double cage and capacity

is 2 tons per cage. “SC200” stands for single cage and capacity is 2 tons.

Q: What is the dimension of the cage?

A: Normally the cage dimension is 3X1.5X2.5M (L/W/H) for 2t type hoist. Details should be checked according to our

quotation sheet. Also, the size can be customized according to the factual site condition. There are two doors (entrance

& exit doors) for each cage, It can be produced as up & down sliding or ramping model for safety and convenience

- Q: Does the misuse or incorrect use of lifting equipment pose a risk of injury to workers?

- <p>Yes, improper or incorrect use of lifting equipment can cause serious injury to workers. This can include accidents such as dropping loads, which can lead to crushing injuries or being struck by falling objects. Additionally, improper lifting techniques can lead to musculoskeletal injuries, such as back strains or sprains. It's crucial for workers to be trained in the safe operation of lifting equipment and to follow all safety protocols to minimize the risk of injury.</p>

- Q: This question seeks to understand the benefits and drawbacks associated with the use of hydraulic building hoists in construction.

- <p>Hydraulic building hoists offer several advantages, including high lifting capacity, smooth and controlled lifting, and lower maintenance costs due to fewer moving parts. They are also energy-efficient and can be easily integrated into existing systems. However, they have some disadvantages. For instance, they can be more expensive to purchase initially compared to other hoist types. Additionally, they may require more space for installation and can be sensitive to extreme temperatures, which might affect performance. Lastly, hydraulic systems can be prone to leaks and require regular fluid checks and maintenance to prevent system failure.</p>

- Q: This question asks whether a building hoist can be utilized in both indoor and outdoor environments for lifting objects.

- <p>Yes, a building hoist can be used both indoors and outdoors for lifting objects. These hoists are designed to handle heavy materials and are often used in construction settings. However, their use is subject to specific conditions and safety requirements. Outdoor use may require additional considerations such as weatherproofing and stability in various weather conditions, while indoor use must adhere to space limitations and structural integrity of the building. Always ensure that the hoist is suitable for the environment and that all safety protocols are followed to prevent accidents.</p>

- Q: This question asks about the measures taken to guarantee the safety and reliability of lifting equipment prior to its use in construction.

- <p>To ensure that lifting equipment is safe and reliable before using it in construction work, several key steps must be taken. Firstly, regular inspections and maintenance are crucial to identify any potential issues or wear and tear. Secondly, all equipment should be thoroughly tested and certified by qualified personnel to meet safety standards. Thirdly, proper training for operators is essential to ensure they understand how to use the equipment safely. Additionally, having a comprehensive safety plan in place, including emergency procedures, can help prevent accidents. Lastly, using equipment from reputable manufacturers and ensuring all components are in good working order are also vital for maintaining safety and reliability.</p>

- Q: This question asks about the process of changing the speed of a building hoist, which is a device used in construction to lift materials.

- <p>Adjusting the speed of a building hoist typically involves accessing the hoist's control panel or motor settings. For electric hoists, this may include adjusting the frequency of the power supply through a variable frequency drive (VFD), which alters the speed of the motor. For manual hoists, speed adjustments might involve changing the gear ratio or the tension on the hoisting rope. Always refer to the hoist's user manual for specific instructions, as different models have different mechanisms. Safety should be a priority; ensure that any adjustments are made by trained personnel and in compliance with safety regulations.</p>

- Q: Excuse me: what is the meaning of heavy weight in the construction elevator?

- This is very nice! Learn more! Thank you for your dedication...

- Q: Is it possible to use a hydraulic cylinder as a substitute for the cylinder in a building hoist?

- <p>While it may be tempting to consider a hydraulic cylinder as a replacement for a building hoist cylinder, it is generally not advisable. Hydraulic cylinders and hoist cylinders serve different purposes and have distinct design specifications. A building hoist cylinder is specifically engineered to handle the vertical lifting and lowering of heavy loads in construction settings, ensuring safety and reliability. Hydraulic cylinders, on the other hand, are used for a variety of applications and may not meet the specific requirements of a hoist, such as load capacity, stroke length, or safety features. Using an inappropriate replacement could lead to mechanical failure, accidents, or even fatalities. It is crucial to use the correct, certified parts for any equipment to maintain safety and functionality.</p>

- Q: This question asks for the criteria or factors to consider when selecting a building hoist for a particular construction task.

- <p>Choosing a suitable building hoist involves considering several factors: the weight capacity required for the materials you need to lift, the height of the building or structure, the frequency of use, and the available space for installation. Ensure the hoist complies with safety standards and regulations. Consider the hoist's speed and efficiency, as well as the ease of maintenance and operation. Consult with hoist manufacturers or experts to assess your specific needs and select the most appropriate model for your construction project.</p>

- Q: Is it possible to replace a building hoist with an electric winch for the purpose of lifting materials or individuals?

- <p>While theoretically possible, using an electric winch instead of a building hoist for lifting materials or people is not recommended due to safety concerns and differences in design. Electric winches are typically designed for pulling or towing loads and may not have the necessary safety features, load capacity, or stability required for lifting operations in a construction setting. Building hoists are specifically engineered to lift heavy materials and personnel safely in vertical shafts or on the facade of a building. They are equipped with safety devices and are regulated for construction use, making them the appropriate choice for such tasks.</p>

- Q: What are the necessary maintenance and inspection procedures for hydraulic building hoists to ensure their safe and efficient operation?

- <p>Hydraulic building hoists require regular maintenance and inspection to ensure safety and efficiency. Daily checks should include visual inspections for leaks, proper functioning of controls, and safe operation of the hoist. Monthly inspections should cover the condition of hydraulic hoses, cylinders, and seals. Annual inspections should be conducted by a qualified professional to check the structural integrity, load-bearing components, and overall mechanical condition of the hoist. Regular lubrication of moving parts and replacement of worn components are also crucial. Always adhere to the manufacturer's guidelines and local regulations for maintenance and inspection intervals.</p>

Send your message to us

CE Approved Construction Hoist, Construction Site Elevator (SC200/200)

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 1000 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords