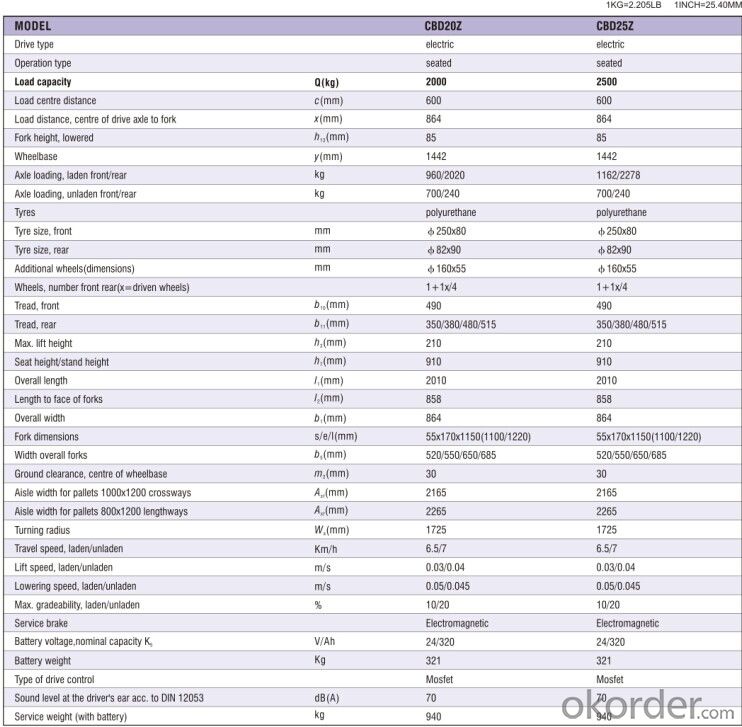

CBD 20Z/25Z ELECTRIC PALLET TRUCK

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

From now on, CNBM team will continually adhered to company general policy “Stronger R&D, Better Quality, More favorable products and Wider promotion” and CNBM Spirit “ Modest Innovation, Hardworking Kindness” integrate the advanced resources and make greater efforts to innovate. CNBM will continue the spirit of : aggressively innovate, dare to pioneer, with traditional marketing-orientation, establishing and preferring the sales service channels, and with E-commerce second, promoting and improving the traditional marketing models.

- Q: What are the potential defects of the automated material handling system?

- In manufacturing and material handling, the automatic pilot (AGV) has become increasingly familiar. But the shuttle, which is introduced here, is based on the equipment that automatically carries the material in the path of the orbit. Machine commonly used in existent shelves, existent shelves for its high space utilization, accepted by a lot of storage and transportation unit, but forklift truck into the tunnel, because the space is narrow, there are shelves safe hidden trouble. In addition, using forklift and human handling inefficient, high cost, on the basis of the original shelves introducing automation machine, in order to improve the automatization level of the whole line production storage and transportation.

- Q: The wear-resisting parts in the broken machine are mainly the direct contact with the material

- There is a need to contact, the crusher is a lot of model and the performance is different. For example: the jaw is broken, the hammer is broken, the fight is broken, the cone is broken... It is. Wear-resisting material is different also, also need according to the material hardness, strength of the material that is broken, the choice is ok. Materials: alloy white iron (high chromium cast iron), high manganese steel, alloy steel (high, medium, low carbon and alloy)... It is. It's best to find experienced manufacturers. Hope to adopt.

- Q: Why should we emphasize unitization and standardization in material handling

- The logistics module is the dimension of the logistics facilities and equipment. The logistics module is for the rationalization and standardization of logistics, the standard scale of various factor dimensions of the logistics system. It is composed of various factors in the logistics system of, these factors include: the group, group the goods loading and unloading machinery, transportation machinery and equipment trucks, trucks, container and transport facilities, machinery and equipment for the cargo storage, etc.

- Q: What is the material handling and handling equipment?

- Lifting equipment Small lifting equipment | gantry crane | | bridge cantilever crane | 2 vertical mechanical unit transportation equipment | gravity conveyor power conveyor parts | | | other comprehensive transportation system

- Q: The function of material handling

- The logistics of mechanical products are very broad and the principle of improving the logistics system is: It enhances the operational training and safety of the handling personnel and increases the efficiency of labor.

- Q: Material handling system in the factory

- Improve logistics quality (material loss, high transport efficiency, safety operation), lower logistics cost (including handling, storage etc.).

- Q: What is the relevant content of the flow of materials, storage and usage

- What is the relevant content of the flow of materials, storage and usage? Material flow, in lean as "one-piece flow," the core idea is how to make the material in the production process is in a state of flow, however it is very difficult, a more realistic approach is to ensure that in the process of circulation between the products is the least (quantity). The real meaning of storage is what you really need at the scene. Using a process is the sequence of steps to complete a task

- Q: What is the carrying equipment of the container cargo

- Shockproof and vacuum packaging, equipment hoisting, lower layer, translation, adjustment level, container (container), import crane, forklift professional service.

- Q: There are three things to do when the material is stacked up and down

- Fire proof, waterproof and center of gravity

- Q: What are the requirements for the science of loading and unloading

- Reduce the load ratio of the mobile carrying equipment. To optimize the utilization rate of transportation equipment and manpower. Plan all the equipment to be maintained and maintained regularly. When there are more efficient means of handling and equipment, it should replace obsolete methods and equipment.

Send your message to us

CBD 20Z/25Z ELECTRIC PALLET TRUCK

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches