Butterfly Valve,Ductile Iron Wafer Butterfly Valve

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Manual Wafer Butterfly Valve Description:

A butterfly valve is a valve which can be used for isolating or regulating flow. The closing mechanism takes the form of a disk. Operation is similar to that of a ball valve, which allows for quick shut off. Butterfly valves are generally favored because they are lower in cost to other valve designs as well as being lighter in weight, meaning less support is required. The disc is positioned in the center of the pipe, passing through the disc is a rod connected to an actuator on the outside of the valve. Rotating the actuator turns the disc either parallel or perpendicular to the flow. Unlike a ball valve, the disc is always present within the flow, therefore a pressure drop is always induced in the flow, regardless of valve position.

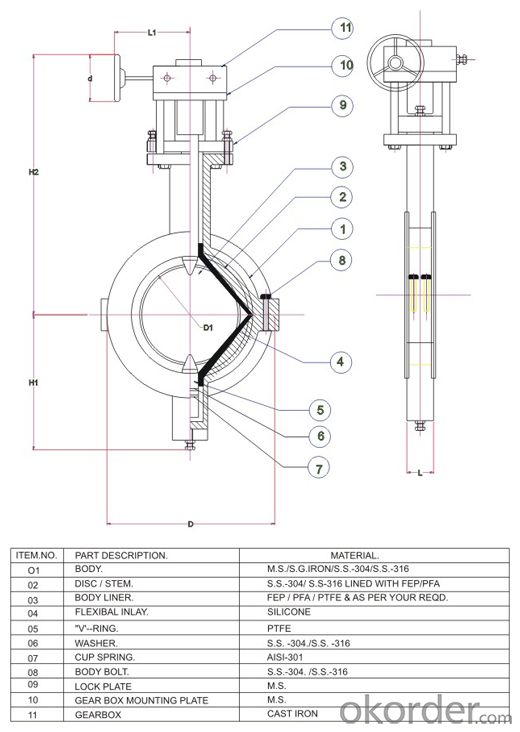

2.Main Features of the Manual Wafer Butterfly Valve

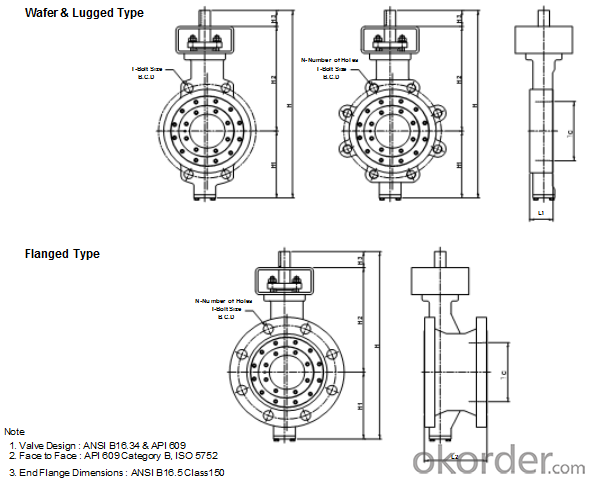

a)Cast hole. Flange connection meet ANSI 125/150# DIN PN10/16 BS4504 PN10/16 in the meanwhile.

b)Soft seat. Replaceable. Increase of service life.

c)Double half shaft without pin.

d) Square and short neck. Easy to stick scutcheon and cost saving.

3. Manual Wafer Butterfly Valve Images:

4.Manual Wafer Butterfly Valve Specification:

5.FAQ

1. What is manual wafer butterfly valve?

A: Wafer style is the more common of the two and is less expensive than the lug style. The wafer style butterfly valve is just about the standard. It ís so common that no one even bothers to use the word "wafer" when ordering a butterfly valve. It is taken for granted that if a butterfly valve is ordered, a wafer style will be received.

2. How about the Installation of the Wafer Style Butterfly Valve?

A: Butterfly valves are installed by inserting the valve between two flanges using bolts or studs and nuts to hold it all together. This type of installation, of course, makes it impossible to disconnect just one side of the piping system from the valve. That benefit is received using the lug style valve.

3. What is the working principle of manual wafer butterfly valve?

A: A butterfly valve is from a family of valves called quarter-turn valves. In operation, the valve is fully open or closed when the disc is rotated a quarter turn. The "butterfly" is a metal disc mounted on a rod. When the valve is closed, the disc is turned so that it completely blocks off the passageway. When the valve is fully open, the disc is rotated a quarter turn so that it allows an almost unrestricted passage of the fluid. The valve may also be opened incrementally to throttle flow.

- Q: What is the difference between valve j941H-40 and j41H-40?

- J941H-40 is an electric globe valve, flange joint, inner part 13Cr, material carbon steel, pressure 40 kg and 4.0MPa, 9 represents electric, 4 represents flange, 1 represents straight through, and J41H-40 is common flange connection

- Q: What does 3/4''mean in the name of the valve?

- Valve diameter, that is, we often say 6 points valve, used in English units, with metric units should be DN20.2 points DN84 points DN156 points DN20 (3/4'')1 inches DN251.2 'DN321.5 'DN402 'DN502.5 'DN653 'DN804 'DN1005 'DN1256 'DN1508 'DN20010 'DN25012 'DN300Nominal diameter (nominal, diameter), also known as the average diameter (mean, outside, diameter).The tube is thin from the metal tube, and the outer diameter of the tube is almost the same as the inner diameter of the tube, so the average value of the outer diameter of the tube and the inner diameter of the pipe is called the diameter.Because the units have metric (mm) and British (inch) distinction, there are the following methods of address.1., based on the metric system (mm), called DN (metric unit)2., on the basis of the British system (inch), called NB (inch unit)DN (nominal, diameter)NB (nominal, bore)OD (outside, diameter)

- Q: Valve connections - two how do different connections work?

- The connection of two different connection forms is achieved by a transition conversion connector

- Q: How about the quality of FITOK valves?

- The United States fitok valve is the main valve and needle valve, globe valve instrument and meter tube also do.The quality of foreign valves are still good. Everyone thinks French valves are better than American ones. But the price is not cheap

- Q: What are the specifications of the valves PN25, DN50?

- PN is the pressure. DN is caliber. In a nutshell, it's the valve of 25bar 50!

- Q: How to check the quality of the valve?

- First, visual inspection of the valve appearance, followed by a spectrometer to check the material, material, and then look at the hydraulic test pressure, whether there is leakage.

- Q: Is the valve galvanized?

- Butterfly valve gate, some hot-dip galvanized, and other valves are not.

- Q: Where is the valve used?

- Generally in the pipeline above, such as the government to improve people's livelihood, engineering, factories and so on the pipeline above, Wenzhou essence valve factory

- Q: What's the name of the valve?

- This is not a valve, it is a pipe bender.

- Q: What kind of valves are best used for sand drain valves?

- Looking at the domestic sand discharge conditions, the more commonly used plate valve and butterfly valve these two, but generally reflect the service life is not long, it will not be long before the sand leakage, the need for regular maintenance, low efficiency, affecting production. In recent years, the industry has also appeared in various kinds of new type of valve, take little effect, but also has a valve using the excellent response, talent shows itself, long service life, no maintenance, model for the special valve industry Yu powder FQD672 and FQD643,It is understood that the valve industry has been to focus on Yu powder (sand) on body condition, especially the delivery of viscous pneumatic conveying system, special valve type FQD672 and type FQD643 powder successfully developed specifically for the design of sand material conditions, erosion resistant, anti adhesive seal design, automatic compensation, to ensure zero leakage absolutely, efficient and longevity, is applied to the resin sand casting industry (coarse sand) sand core shape of the high-speed exhaust conditions, you can try to understand Baidu......

Send your message to us

Butterfly Valve,Ductile Iron Wafer Butterfly Valve

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords