Building Hoist SCD200/200 Payload 2*2000kg

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 30 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Structure of Building Hoist Description

Feature: Building hoist Condition: New Application: Construction

Payload(kg):2*2000 Lifting Speed(m/min):0~60 Motor Power(kw): 2*2*15

Safety Device: 2*SAJ40-1.4 Cage: Twin Counterweight: Yes

Certification: CE,ISO Place of Origin: China(Mainland) Model Number: Type:SCD200/200

Packaging & Delivery of Building Hoist

Packaging Detail: Nude package Delivery Detail: 25-30days

Main Parts of Building Hoist

● Adopts the most advanced VF speed control device and microcomputer programmable logic controller.

● Stepless speed control helps eliminate the concussion during start up and braking, steady the operation process,

and ensures automated leveling.

● Adopts open loop V/Fcontrol; the speed control precision can reach ±2~3%. Realizes accurate low speed positioning of the hoist and avoid slipping during downward stopping of hoist.

● The VF system has current-restriction function, ensuring a small current when motor start up and reducing the concussion to power supply. It reduces the engery consumption and mitigates effects to on site electric equipments.

● The steadiness during running mitigates concussion to mechanical parts, reduces wears of rack, pinion and the brake

and prolongs the spare parts'life.

● The VF system also has the over voltage protection,low voltage protection, overcurrent, overload and anti-stalling protection functions,

● The system applies the special software for hoists developed by our company, making the operation more safe and

reliable.

Building Hoist Images

CMAX Building Hoist

Anchorage System

Mast Section

Driving Unit

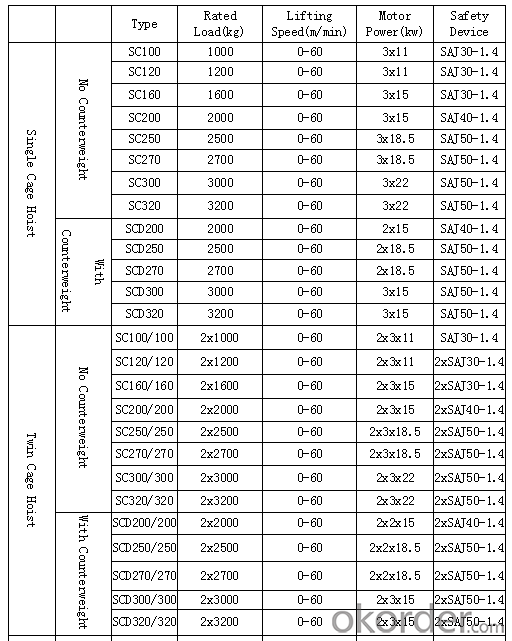

Building Hoist Specifiction

FAQ of Building Hoist

Q: What is the building hoist main purpose?

A: Building hoist equipped with double or single cabin to transport the materials and labors up and down. It's the ideal

construction equipment for vertical transportation in the field of construction.

Q: What is the main structure of building hoist?

A: The P/M construction hoist mainly contains metal structure, driving system, electrical control system, cable guide &

protection system, electrical top crane and safety device.

Q: What is the meaning of the building hoist’s code?

A: Take SC200/200 for example: “SC” stands for rack and pinion hoist, “200/200” stands for double cage and capacity

is 2 tons per cage. “SC200” stands for single cage and capacity is 2 tons.

Q: What is the dimension of the cage?

A: Normally the cage dimension is 3X1.5X2.5M (L/W/H) for 2t type hoist. Details should be checked according to our

quotation sheet. Also, the size can be customized according to the factual site condition. There are two doors (entrance

& exit doors) for each cage, It can be produced as up & down sliding or ramping model for safety and convenience.

- Q: Is it possible to operate a building hoist without undergoing professional training?

- <p>No, it is not advisable to use a building hoist without professional training. Operating a building hoist requires specific skills and knowledge to ensure safety and prevent accidents. Training programs teach the proper use of controls, safety procedures, and how to handle emergencies. Non-compliance with this can lead to severe injuries or fatalities. Always ensure you are adequately trained and certified before operating any hoisting equipment.</p>

- Q: Is it possible to fix a building hoist or substitute it with alternative lifting machinery?

- <p>Yes, a building hoist can be repaired if the damage is not severe. If repair is not feasible or cost-effective, it can be replaced by other types of lifting equipment. There are various alternatives available, such as cranes, forklifts, and material hoists, each with its own advantages and suitable for different scenarios. The choice depends on factors like the weight of the load, the height of the building, and the specific requirements of the construction project. It's essential to consider safety, efficiency, and compatibility with the existing infrastructure when making such decisions.</p>

- Q: Is it possible to repair or replace a hydraulic pump used in a building hoist system?

- <p>Yes, a hydraulic pump used in a building hoist can be repaired or replaced. If the pump is damaged or worn out, it can be serviced or repaired by professionals who specialize in hydraulic systems. If the damage is beyond repair, a new pump can be sourced and installed to ensure the hoist operates safely and efficiently. Regular maintenance and inspection are crucial to prevent major issues and to extend the life of the hydraulic pump.</p>

- Q: This question asks about the various types of control systems used in building hoists, which are essential for the safe and efficient operation of construction elevators.

- <p>There are several types of building hoist control systems that ensure the safe and efficient operation of construction elevators. These include: 1. Manual Control Systems: Operated by a human operator who controls the hoist's movement. 2. Semi-Automatic Control Systems: Combine manual operation with some automated features, like automatic level selection. 3. Fully Automatic Control Systems: Completely automated, with the hoist moving between floors without manual intervention. 4. Microprocessor-Based Control Systems: Utilize advanced microprocessors for precise control and monitoring. 5. PLC-Based Control Systems: Use Programmable Logic Controllers for robust and customizable control. 6. Wireless Control Systems: Enable remote operation and monitoring of the hoist. Each system has its advantages and is chosen based on specific project requirements, safety standards, and budget considerations.</p>

- Q: What is the main function of elevator motherboard?

- The elevator motherboard is different from each brand, and it functions like a computer motherboard

- Q: What are the steps and considerations for maintaining a building hoist to ensure its safety and functionality?

- <p>To maintain a building hoist properly, follow these steps: Regularly inspect the hoist for any visible damage or wear. Lubricate moving parts as per manufacturer's recommendations. Ensure all safety devices are functioning correctly, including limit switches and emergency stop buttons. Check the hoist's electrical system for any signs of damage or wear. Keep the hoist clean and free from debris. Conduct a thorough inspection after any incident or near miss. Regularly test the hoist's load capacity to ensure it is within safe limits. Train operators on safe hoist operation and maintenance procedures. Always follow the manufacturer's guidelines and local regulations for maintenance and inspection.</p>

- Q: Is it possible to utilize a double-rope lifting mechanism within the context of a building hoist?

- <p>Yes, a double-rope lifting system can be used in a building hoist. This system offers advantages such as increased safety due to redundancy and the ability to lift heavier loads compared to a single-rope system. The double-rope setup allows for the hoist to handle the load with two separate ropes, reducing the risk of failure and providing a more stable lifting platform. It's common in applications where high load capacities and safety are paramount, such as in construction for lifting materials and equipment.</p>

- Q: This question asks whether a building hoist can be utilized to lift various objects with differing weights and dimensions.

- <p>Yes, building hoists are designed to lift a variety of objects with different weights and sizes. They are versatile and adjustable, allowing for the transportation of materials such as bricks, concrete, and equipment. However, each hoist has a specific weight capacity that must not be exceeded. It's crucial to ensure that the objects being lifted are within the hoist's capacity and that the hoist is properly configured for the size and shape of the objects to ensure safety and efficiency.</p>

- Q: Is it possible to utilize building hoists for construction purposes?

- <p>Yes, building hoists are commonly used in construction work. They are essential for lifting and lowering materials, tools, and sometimes personnel between different floors of a building under construction. These hoists enhance efficiency by reducing manual labor and improving safety by minimizing the risk of accidents associated with manual handling of heavy loads. They are designed to be robust and reliable, making them a vital piece of equipment in the construction industry.</p>

- Q: This question asks for a description of the process of using a hydraulic cylinder in the context of a building hoist.

- <p>To use a hydraulic cylinder in a building hoist, first ensure the hoist is properly installed and secured. Connect the hydraulic cylinder to the hoist's power source, typically a hydraulic pump. The pump pressurizes hydraulic fluid, which is then directed into the cylinder. As the fluid enters, it pushes a piston within the cylinder, causing it to extend and lift the load. To lower the load, the fluid is released from the cylinder, allowing the piston to retract. Always monitor the pressure and ensure the system is leak-free for safe operation. Regular maintenance, including checking seals and lubricating parts, is crucial to prolong the life of the hydraulic cylinder and ensure efficient hoist performance.</p>

Send your message to us

Building Hoist SCD200/200 Payload 2*2000kg

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 30 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords