Building Hoist Hot Galvanizing Mast Section with Max 3.2ton Capacity

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 10 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

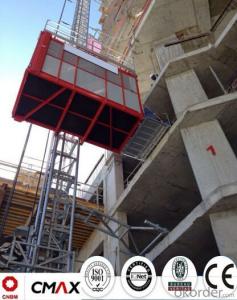

Structure of Building Hoist with Max 3.2tons Capacity Description

The hoist can be widely used in industrial and civilian construction, bridge, under well, big chimney as well as shipping industry to carry people and materials. As permanent or semi-permanent equipment, hoist can be used in different sites such as warehouse, high tower, etc.

With the advantages of reliable performance, safety, easy carrying, high adaptability, it can reduce operators’ work intensity.

With many advanced technology integrity, strict control on each making process, high ratio of price and quality, CMAX hoist has become a symbol of lifter with high quality and excellent after-sales service.

Packaging & Delivery of Building Hoist with Max 3.2tons Capacity

Packaging: nude and wooded box Delivery: 25-30days

Mains Parts of Building Hoist with Max 3.2tons Capacity

1.Metal structure including the mast, tie in and cabin ,could be spay-painted and hot galvanized. Mast section is produced with high quality Q345B seamless steel pipe.

2.The electrical system can be adopted with the normal control method and VVVF+PLC control method. Inverter we adopted is from Schneider. Yaskawa and other world famous brand.

3.Electric parts are all equipped with Schneider , Siemens and other top brands.

4.Cabin exit door adopts ramping type. The ramping door likes a bridge between the building hoist and construction building.

Building Hoist with Max 3.2tons Capacity Images

Building Hoist with Max 3.2tons Capacity Specification

FAQ of Building Hosit with Max 3.2ons Capacity Capacity

Q: What is the main structure of building hoist?

A: The P/M construction hoist mainly contains metal structure, driving system, electrical control system, cable guide & protection system, electrical top crane and safety device.

Q: What is the building hoist main purpose?

A: Building hoist equipped with double or single cabin to transport the materials and labors up and down. It's the ideal construction equipment for vertical transportation in the field of construction.

- Q: Is it possible to utilize a building hoist for the purpose of lifting heavy equipment or machinery?

- <p>Yes, a building hoist can be used for lifting heavy equipment or machinery, provided it has the necessary capacity and safety features. These hoists are designed to handle substantial loads and are commonly used in construction for moving materials and equipment. However, it's crucial to ensure that the hoist is rated for the weight of the equipment, and all safety protocols are followed to prevent accidents. Regular maintenance and inspection are also essential to ensure the hoist's reliability and safety during heavy lifting operations.</p>

- Q: This question asks for a description of the process of using an electric motor in the context of a building hoist, which is a device used for lifting and lowering materials in construction.

- <p>To use an electric motor with a building hoist, first ensure the hoist is properly installed and secured. Connect the hoist to a power source and check that all safety features are operational. Turn on the motor and test the hoist's movement in both directions to confirm functionality. When lifting materials, ensure they are evenly distributed and securely attached to the hoist. Operate the motor to lift or lower the load, maintaining a steady speed and monitoring for any signs of strain or malfunction. Always follow the manufacturer's guidelines and safety precautions to prevent accidents.</p>

- Q: This question asks if a building hoist can be utilized for the purpose of lifting heavy objects.

- <p>Yes, a building hoist is specifically designed for lifting heavy objects in construction settings. It is a mechanical device that can lift and lower materials such as concrete, bricks, and tools to various levels of a building under construction. Building hoists are engineered to handle substantial weight and are equipped with safety features to ensure secure and efficient operation. However, it is crucial to adhere to the hoist's weight capacity and safety guidelines to prevent accidents and ensure the proper use of the equipment.</p>

- Q: What are the benefits and drawbacks of utilizing a building hoist in construction?

- <p>Advantages of using a building hoist include increased efficiency in material transportation, reduced manual labor, and improved safety by minimizing the risk of accidents associated with manual handling. They can also speed up construction timelines by allowing for continuous material flow. Disadvantages include the initial cost of the hoist, the need for regular maintenance, and potential downtime in case of mechanical failure. Additionally, building hoists may have limited capacity and may not be suitable for all types of construction projects, especially those with irregular shapes or limited space for installation.</p>

- Q: This question asks for an identification of the various types of lifting equipment that are specifically utilized in the context of building hoists.

- <p>Different types of lifting equipment used for building hoists include: 1. Electric Chain Hoists, which are versatile and suitable for various lifting tasks. 2. Manual Chain Hoists, that require manual operation and are used for lighter loads. 3. Electric Wire Rope Hoists, known for their high lifting capacity and durability. 4. Air Hoists, which are powered by compressed air and are ideal for environments where electricity is hazardous. 5. Geared Winches, used for pulling or lifting heavy loads with precision. 6. Jib Cranes, which provide a fixed or semi-fixed lifting solution in workshops. 7. Gantry Cranes, used for lifting heavy loads over a specific area. Each type serves specific purposes and is chosen based on the weight, environment, and specific requirements of the construction project.</p>

- Q: Is it possible to repair or replace a hydraulic pump used in a building hoist system?

- <p>Yes, a hydraulic pump used in a building hoist can be repaired or replaced. If the pump is damaged or worn out, it can be serviced or repaired by professionals who specialize in hydraulic systems. If the damage is beyond repair, a new pump can be sourced and installed to ensure the hoist operates safely and efficiently. Regular maintenance and inspection are crucial to prevent major issues and to extend the life of the hydraulic pump.</p>

- Q: This question asks for methods to protect lifting equipment from damage while it is being transported or stored.

- <p>To prevent damage to lifting equipment during transportation or storage, follow these guidelines: 1. Use protective covers or wraps to shield equipment from environmental elements. 2. Securely fasten equipment to prevent movement during transit. 3. Store equipment in a dry, clean area to avoid rust and dirt accumulation. 4. Regularly inspect equipment for signs of wear or damage before and after use. 5. Follow the manufacturer's guidelines for weight limits and proper handling. 6. Use padding or cushioning materials to protect equipment from impacts. 7. Ensure that all parts are properly lubricated to prevent rust and facilitate smooth operation. By adhering to these practices, you can significantly reduce the risk of damage to lifting equipment.</p>

- Q: This question asks whether it is safe to operate a building hoist in adverse weather conditions such as wind and rain.

- <p>The use of a building hoist in windy or rainy weather is generally not recommended due to safety concerns. Wind can cause instability and swaying of the hoist, while rain can lead to slippery conditions and electrical hazards. Most hoist manufacturers and safety guidelines advise against operating hoists in such conditions. However, if absolutely necessary, it should be done with extreme caution, following specific safety protocols, and ensuring all necessary weatherproofing and stability measures are in place. Always consult the manufacturer's guidelines and local regulations before operating a hoist in adverse weather.</p>

- Q: Explain the key differences between electric and pneumatic lifting equipment in a few sentences.

- <p>Electric lifting equipment is powered by electricity and offers precise control, high efficiency, and is suitable for heavy-duty applications. Pneumatic lifting equipment, on the other hand, is powered by compressed air and is known for its simplicity, safety, and lower cost. It is often used in environments where electrical equipment might be hazardous, such as in the presence of flammable gases or dust. Electric systems can handle heavier loads and provide more precise control, while pneumatic systems are more resistant to overload and offer a fail-safe mechanism in case of air pressure loss.</p>

- Q: What are the necessary steps and checks required to maintain a building hoist to ensure its safe and efficient operation?

- <p>Building hoists require regular maintenance to ensure safety and efficiency. This includes daily inspections of the hoist's mechanical and electrical components for any signs of wear or damage. Monthly, a thorough inspection should be conducted by a qualified technician, including checking the hoist's cables, brakes, and safety devices. Lubrication of moving parts and replacement of worn components are also crucial. Annually, a comprehensive inspection and certification by a professional is necessary to comply with safety regulations. Adherence to the manufacturer's guidelines is essential, and any malfunctions should be addressed immediately to prevent accidents.</p>

Send your message to us

Building Hoist Hot Galvanizing Mast Section with Max 3.2ton Capacity

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 10 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords