black galvanized steel h beam universal beam steel h post h section

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 200000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

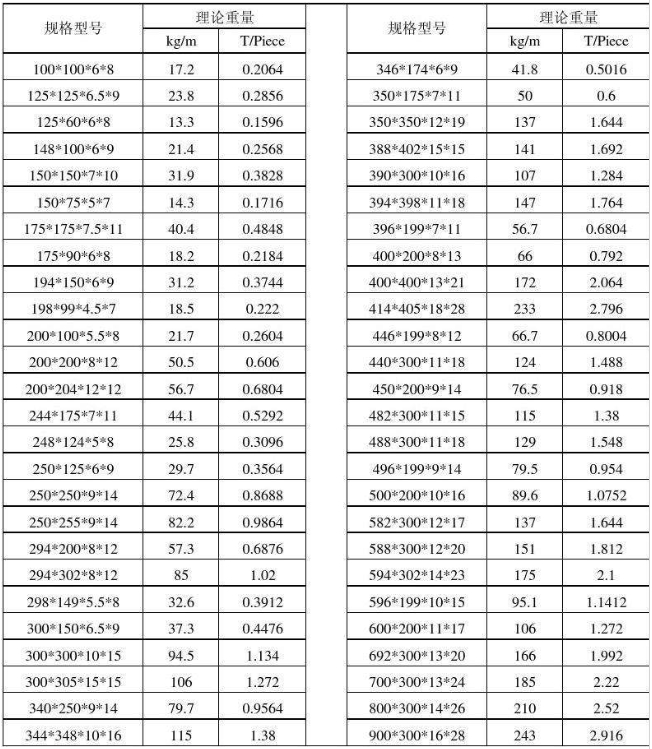

Specification

We supply ms equal & unequal angle bar, channel bar,jis channel, upn, steel i beam,h beam, ipe, ipeaa, steel sheet pile, flat bar, hollow section, tmt bar, wire rod, binding wire, wire mesh, hrc, CRC, gi coil, ppgi, roofing sheet, chequered coil & plates, medium plate, scaffolding systems, prefabricated container houses etc. Also for metal & steel processing.

If you are in the market for any steel products, please feel free to contact us.

Steel Beams are widely used throughout the construction industry when supporting heavy loads is required. Commonly termed an “I” Beam because of its shape, beams provide great load bearing support when used horizontally or standing as columns. Available in two configurations, the most popular being the Wide Flange Steel Beam aka H Beam or W Beam with non-tapered flanges. This beam shape has a wider profile for added horizontal strength, making it ideal for skyscrapers or as a house beam, along with bridge beams, trailers, platforms, etc. Standard American Beams, aka Junior Beams or S Beams, have tapered flanges for added strength when your load is concentrated on the flanges, such as machine bases, hoists, cranes or a trolley beam for your garage.

- Q: Can steel H-beams be used in the construction of museums and art galleries?

- Certainly, museums and art galleries can indeed utilize steel H-beams in their construction. Renowned for their robustness and longevity, steel H-beams possess the capability to bear substantial loads and endure structural strains, rendering them suitable for this purpose. These beams offer exceptional structural support, facilitating the creation of spacious areas and flexible layouts within the museum or art gallery. Additionally, steel H-beams can be tailored to various dimensions and lengths, providing flexibility in terms of design and construction. Furthermore, the sleek and contemporary appearance of steel beams can harmonize with the overall architectural style and design of the museum or art gallery. Overall, owing to their strength, durability, and versatility, steel H-beams are widely favored within the construction industry as an ideal material for museums and art galleries.

- Q: How do steel H-beams perform in earthquakes?

- Due to their high strength and stiffness, steel H-beams are extensively utilized in construction. When it comes to earthquakes, these beams are renowned for their exceptional performance and resilience. The effective distribution and dissipation of energy generated during an earthquake is made possible by the design of steel H-beams. Their inherent strength and rigidity enable them to endure the lateral forces and vibrations caused by seismic activity. Throughout an earthquake, the H-beams function as load-bearing elements, providing structural stability to the building. Their shape and cross-section enable them to resist bending and twisting forces, thereby minimizing the risk of collapse. Furthermore, steel H-beams possess a remarkable level of ductility, allowing them to deform significantly before failure. This characteristic enables them to absorb and dissipate seismic energy, thereby reducing the impact on the overall structure. In addition to their strength and ductility, steel H-beams also offer advantages in terms of construction speed and flexibility. They can be easily prefabricated off-site and quickly assembled on-site, making them a favored choice for earthquake-resistant buildings. All in all, the effectiveness of steel H-beams in earthquake-prone areas has been proven. Their capacity to withstand and absorb seismic forces establishes them as a dependable and secure option for constructing buildings and structures that must endure earthquakes.

- Q: What are the different grades of Steel H-Beams available?

- In the market, one can find various grades of Steel H-Beams. A36, A572, and A992 are among the most frequently utilized grades. A36, widely employed for general structural purposes, is a low carbon steel. It possesses a yield strength of 36,000 psi and a tensile strength ranging from 58,000 to 80,000 psi. Construction projects, bridges, and machinery often utilize A36 H-Beams. A572, on the other hand, is a high-strength, low-alloy steel that surpasses A36 in terms of strength and hardness. It has a yield strength of 42,000 to 65,000 psi and a tensile strength of 60,000 to 80,000 psi. A572 H-Beams are commonly found in heavy construction, infrastructure development, and projects necessitating high strength. A992, a widely used structural steel grade, boasts superior mechanical properties. It possesses a yield strength of 50,000 to 65,000 psi and a tensile strength of 65,000 to 85,000 psi. High-rise buildings, bridges, and demanding applications that require exceptional strength and stability often employ A992 H-Beams. Less commonly used grades of Steel H-Beams include A588, A514, and A709, each offering specific properties and characteristics suitable for particular applications. To determine the most suitable grade of Steel H-Beams for a specific project or application, it is crucial to consult with a steel supplier or engineer.

- Q: Can Steel H-Beams be used in data center or IT facility construction?

- Data center or IT facility construction can indeed utilize Steel H-Beams. These H-Beams are commonly employed in commercial construction projects owing to their structural strength and versatility. With exceptional load-bearing capabilities, they are an ideal choice for supporting heavy equipment and infrastructure in data centers and IT facilities. Furthermore, Steel H-Beams possess durability, fire resistance, and the ability to withstand extreme weather conditions, ensuring the safety and longevity of the facility. Their flexibility allows for effortless customization and expansion, which proves crucial in dynamic environments such as data centers. All in all, Steel H-Beams offer a dependable and efficient solution for constructing data centers or IT facilities.

- Q: What are the different joining techniques used for connecting steel H-beams?

- Steel H-beams can be connected using various techniques to ensure secure connections and withstand loads and forces. Some commonly used techniques include welding, bolting, riveting, adhesive bonding, and mechanical connectors. Welding is widely used and involves melting the edges of the beams together using heat. While it provides a strong connection, skilled labor and proper techniques are necessary to ensure joint quality. Bolting, another common method, uses bolts, nuts, and washers to connect the beams. It offers a strong and durable connection and allows for easy disassembly and reassembly, making it less time-consuming than welding. Riveting, an older technique, uses metal pins or rivets to connect beams. It requires drilling holes and securing the joint by hammering or compressing the rivets. Although it provides a strong connection, it is less commonly used nowadays due to more efficient techniques. Adhesive bonding uses high-strength adhesives or epoxy resins to bond beams together. It provides a lightweight and flexible connection but may not be suitable for high load-bearing applications or significant temperature variations. Mechanical connectors like beam clamps or angle brackets offer a quick and easy connection without the need for welding or drilling. They are commonly used in construction projects where time and efficiency are crucial. The choice of joining technique depends on factors such as structural requirements, load-bearing capacity, project specifications, and budget. Consulting a structural engineer or qualified professional is recommended to determine the most suitable technique for connecting steel H-beams in a specific application.

- Q: Are steel H-beams compatible with different types of flooring materials?

- Certainly, various types of flooring materials can be used in conjunction with steel H-beams. Construction projects often rely on steel H-beams as structural supports, which can be paired with concrete, wood, or composite materials for flooring. Steel's strength and stability make it a flexible option for supporting different flooring systems. Moreover, steel H-beams can be customized to meet specific load demands, guaranteeing compatibility with diverse flooring materials and supporting a vast array of construction applications.

- Q: Are Steel H-Beams resistant to warping or bowing over time?

- Steel H-Beams exhibit exceptional resistance against warping or bowing as time passes. This remarkable durability stems from their structural design and the inherent qualities of steel. H-Beams undergo manufacturing processes that result in a high strength-to-weight ratio, enabling them to bear hefty loads while retaining their form for extended durations. Furthermore, steel boasts outstanding dimensional stability, making it less susceptible to expansion or contraction caused by temperature or moisture fluctuations in comparison to alternative materials. These remarkable attributes establish Steel H-Beams as a dependable option for construction endeavors that prioritize long-term stability.

- Q: How do steel H-beams perform in termite-prone areas?

- Steel H-beams are highly resistant to termite damage due to their material composition. Unlike wood, which is vulnerable to termite infestation, steel is an inorganic material that termites cannot consume or damage. Therefore, steel H-beams are an excellent choice for construction in termite-prone areas as they provide long-lasting structural integrity without the risk of termite-related issues.

- Q: What are the considerations when designing for sustainable materials in Steel H-Beams?

- When it comes to designing Steel H-Beams with sustainable materials, there are several important factors to consider. These considerations revolve around the impact on the environment, the cost-effectiveness, the durability, and the overall sustainability of the materials used. 1. Environmental Impact: When incorporating sustainable materials, it is crucial to minimize the environmental impact throughout the lifecycle of the H-Beams. This can be achieved by responsibly sourcing materials from forests that are managed well or by utilizing recycled steel, which helps reduce deforestation and carbon emissions. 2. Energy Efficiency: Another crucial factor to consider is the energy efficiency of the manufacturing process. Designers should aim to reduce energy consumption and greenhouse gas emissions by selecting materials that require less energy to produce or by using energy-efficient manufacturing techniques. 3. Durability and Longevity: Sustainable materials should be durable and have a long lifespan. By designing H-Beams that are resistant to corrosion, wear, and tear, it reduces the need for frequent replacements, thereby minimizing waste and resource consumption. 4. Recyclability: The ability to recycle and reuse materials is essential in sustainable design. Steel H-Beams should be designed in a way that allows for easy disassembly and recycling at the end of their lifespan. This promotes a circular economy and reduces the demand for new raw materials. 5. Cost-effectiveness: While sustainability is a primary goal, it is also important to consider the cost-effectiveness of the materials used. Designers should strive to strike a balance between sustainability and affordability, ensuring that the use of sustainable materials does not compromise the overall project budget. 6. Compliance with Standards and Certifications: Designers should consider materials that meet recognized sustainability standards and certifications, such as LEED (Leadership in Energy and Environmental Design) or Cradle to Cradle. These certifications ensure that the materials have been responsibly sourced and manufactured. 7. Collaborative Approach: Finally, it is crucial to involve stakeholders, including architects, engineers, and manufacturers, in the decision-making process. By collaborating and sharing knowledge, the design team can identify innovative solutions that promote sustainability and address any challenges related to using sustainable materials in Steel H-Beams.

Send your message to us

black galvanized steel h beam universal beam steel h post h section

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 200000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products