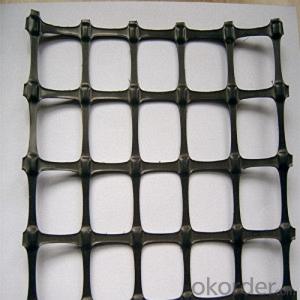

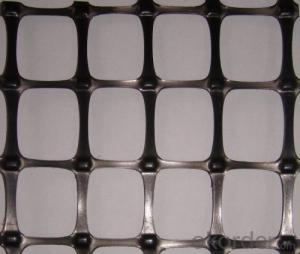

Class 4 Geotextile Fabric Biaxial Geogrids for Jetty, Road, and Tunnel Construction

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Introduction

PET geogrid

15X15,20X20,25X25,30X30,35X35,40X40,50X50,60X60.

70X70,80X80,90X90,100X100,110X110KN

steel-plastic composite geogrid

20X20,30X30,40X40,50X50,60X60,70X70,80X80,90X90,

100X100KN

PP geogrid 20X20,30X30,40X40,50X50,60X60,70X70,80X80,90X90,

100X100,110x110KNRoad bed reinforcement-it can effectively allocate and disperse load,improve the stability and load capacity of road bed and extend the useful lfe of road

color:

black

certification:

ISO9001,ISO14001

standard:

GB/T 17639-2008

MOQ:

5000m2

Place of origin:

Shandong,China

packing:

according to customer's need

Our Service

Quality assurance

1.On a regular basis or as per your request,we entrust national testing agencies to conduct quality inspections

2. Strictly in accordance with the ISO9001-2008 international quality system standard,we monitor and manage the whole process throughout production,quality testing,and measurement to ensure product quality

3. For quality-related construction delay or substandard construction(except for damage or losses due to customer’s responsibility or irresistible natural disasters),we have refunding,replacement,and repair services.We will respond to customers’ feedbacks on quality issues within 24 hours.

Packaging & Shipping

Packing: PLASTIC FILM INSIDE, AND WOVEN BAG OUTSIDE

Shipping: About 15 days after receipt the deposit

FAQ:

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

Q: Do you have other products?

A: Yes, please check the pictures:

- Q: How do geotextiles aid in the reduction of liquefaction?

- Geotextiles aid in the reduction of liquefaction by providing reinforcement and stabilization to the soil. These synthetic fabrics are installed beneath the surface to improve the soil's strength and prevent its excessive movement during seismic activity. By increasing the soil's resistance to liquefaction, geotextiles help to mitigate the potential damage and hazards caused by this phenomenon.

- Q: Road with a geotextile cloth is a cloth or non-woven fabrics

- Geotextile is a non-woven category, geomembrane is divided into light film, and a cloth a film, two cloth a film, two cloth is a film in the middle of the membrane, both sides of the geotextile composite products. Huazhi geotextile material manufacturers

- Q: What are the key considerations for geotextile installation in high water flow areas?

- Some key considerations for geotextile installation in high water flow areas include selecting a geotextile material with a high flow rate to allow for effective water drainage, ensuring proper anchoring and securing of the geotextile to prevent displacement, conducting thorough site investigations and assessments to determine the appropriate installation method and design, and monitoring the performance of the geotextile over time to identify any maintenance or repair needs. Additionally, considering the environmental conditions and potential impact on the geotextile's durability is crucial in high water flow areas.

- Q: Water stability grassroots health permeable geotextile or plastic film is good?

- 1, geotextile cloth, high unit price. 2, plastic film poor maintenance, generally do not. 3, moisturizing cotton, grass mountain child with more.

- Q: Concrete platform this time to water conservation?

- You say this is the road maintenance geotextile, is a one-time use, and its main role is to prevent the concrete quick-drying and the formation of cracks, the correct approach is that the concrete surface completely hardened before, to keep the geotextile moist, dry.

- Q: What is the meaning of the geotextile What is its working principle

- Hot geotextile cloth is to isolate the heat and cover a layer of geotextile material. Advantages: light weight, the overall continuity is good, high tensile strength, corrosion resistance, anti-microbial erosion is good, easy construction. Non-woven geotextile properties: small pore diameter, good permeability, soft texture, and soil with a good combination. 2, construction (1) according to the embankment or base wide full section laying. (2) leave sufficient anchorage length on each side of the embankment or substrate. (3) To ensure integrity, when the lap method is continuous, the lap length should be 0.3 ~ 0.5m. When the seam is connected, the bond width is not less than 50mm. (4) site construction, material damage must be immediately repaired. Upper and lower seams should be alternately staggered, staggered length of not less than 0.5m. (5) try to avoid prolonged exposure.

- Q: Are geotextiles recyclable?

- Yes, geotextiles are recyclable.

- Q: Are geotextiles commonly used in riverbank protection applications?

- Yes, geotextiles are commonly used in riverbank protection applications. They are used to stabilize the soil, prevent erosion, and provide a barrier against high water flow. Geotextiles are often preferred due to their durability, permeability, and ability to withstand harsh environmental conditions.

- Q: Are geotextiles resistant to puncture?

- Yes, geotextiles are generally resistant to puncture due to their strong and durable construction.

- Q: What are the limitations of geotextiles?

- Some limitations of geotextiles include their vulnerability to UV degradation, limited effectiveness in high flow conditions, and potential for clogging with fine particles. Additionally, geotextiles may not be suitable for certain applications where high strength or puncture resistance is required.

Send your message to us

Class 4 Geotextile Fabric Biaxial Geogrids for Jetty, Road, and Tunnel Construction

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords