Aluminum Pig/Ingot With Best Price From China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Pure Aluminum Pig/Ingot Used for Industry

1.Structure of Aluminum Pig/Ingot

A material that has been cast into a shape in order to be transported and processed easier than in an unprocessed form. An ingot is typically rectangular in shape, which allows it to be stacked. Ingots are most commonly associated with metals, with ingots of gold held in the vaults of banks and brokerages being popular images.

Aluminum Ingot is with the AL as the main chemical composition.Aluminum Ingot is used for industry,such as automobile,pinning and weaving,electron broadly and so on. Aluminum Ingot has the following advantages: easy control and operation, fast melting.

2.Main Features of the Aluminum Pig/Ingot

•High Purity

•Easy control and operation

•High strength

•Fast melting

•Competitive price

•Best Service

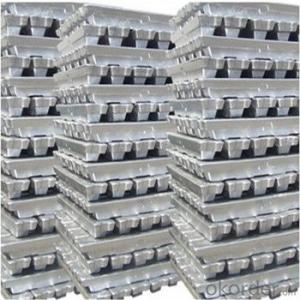

3.Aluminum Pig/Ingot Images

4.Aluminum Pig/Ingot Specification

Grade | Chemical Composition % | |||||||||

Al≥ | impurities ≤ | |||||||||

Si | Fe | Cu | Ga | Mg | Zn | Mn | others | Sum | ||

Al99.9 | 99.90 | 0.50 | 0.07 | 0.005 | 0.02 | 0.01 | 0.025 | - | 0.010 | 0.10 |

Al99.85 | 99.85 | 0.80 | 0.12 | 0.005 | 0.03 | 0.02 | 0.030 | - | 0.015 | 0.15 |

Al99.7 | 99.70 | 0.10 | 0.20 | 0.010 | 0.03 | 0.02 | 0.030 | - | 0.030 | 0.30 |

Al99.6 | 99.60 | 0.16 | 0.25 | 0.010 | 0.03 | 0.03 | 0.030 | - | 0.030 | 0.40 |

Al99.5 | 99.50 | 0.22 | 0.30 | 0.020 | 0.03 | 0.05 | 0.050 | - | 0.030 | 0.50 |

Al99.00 | 99.00 | 0.42 | 0.50 | 0.020 | 0.03 | 0.05 | 0.050 | - | 0.050 | 1.00 |

5.FAQ of Aluminum Pig/Ingot

We have organized several common questions for our clients,may help you sincerely:

①How about your company?

A professional manufacturers of the alumiun pig.Devoted in this industry for many years,so got much experice.The quality and service have also accepted by customer.Can meet customers' requiements to provide different grade and purity alumiun pig.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the prod rking days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 7 to 10 working days can be served.

- Q: What are the main components of aluminum ingots?

- Aluminum ingots primarily consist of aluminum metal, containing small amounts of impurities. They are produced through the smelting of aluminum ore, typically bauxite, which contains aluminum oxide. The ore undergoes processing to extract the aluminum oxide, which is then refined and melted to create the ingots. These ingots generally contain 99% or more pure aluminum, with the remaining percentage comprising impurities like silicon, iron, copper, magnesium, and other elements. The specific production process and quality of raw materials used may cause variations in the impurity composition. Nonetheless, the high purity of aluminum ingots ensures their suitability for diverse industrial applications, including the manufacturing of various aluminum products.

- Q: What is the tensile strength of aluminum ingots?

- The specific alloy and manufacturing process employed can cause variations in the tensile strength of aluminum ingots. On average, the tensile strength of these ingots falls within the range of 70 to 700 megapascals (MPa). It is crucial to consider that factors like the purity level, presence of impurities, and the heat treatment process can influence the tensile strength. Moreover, different aluminum alloys exhibit distinct tensile strengths, necessitating the specification of the alloy in order to determine the tensile strength of aluminum ingots accurately.

- Q: How much is a ton of aluminium ingots?

- If the die cast aluminum ingots, such as ADC12, are more expensive

- Q: How are aluminum ingots used in the production of lighting fixtures?

- Aluminum ingots are used in the production of lighting fixtures as they serve as the primary material for constructing the fixtures' bodies and frames. The ingots are melted down and then cast into various shapes and sizes, allowing manufacturers to create durable and lightweight components for the fixtures. Additionally, the aluminum's excellent thermal conductivity helps dissipate heat efficiently, making it a suitable material for light fixtures that require effective heat management.

- Q: Want to melt the cans into aluminium ingots, but what about iron cans?

- Silver light metal. Ductility. Goods are often made in bars, sheets, foils, powders, ribbons, and filaments. A layer of oxide film that prevents metal corrosion is formed in moist air. Aluminum powder and aluminum foil heated in the air can burn violently and give a dazzling white flame. Soluble in dilute sulfuric acid, nitric acid, hydrochloric acid, sodium hydroxide and potassium hydroxide solution, insoluble in water. Relative density 2.70. Melting point 660 DEG C. Boiling point 2327 DEG C.

- Q: What are the different surface treatments for aluminum ingots?

- Some common surface treatments for aluminum ingots include anodizing, powder coating, painting, and polishing. Anodizing involves creating a protective oxide layer on the surface of the ingot, while powder coating and painting provide a decorative and protective coating. Polishing is done to enhance the appearance and smoothness of the aluminum surface.

- Q: How are aluminum ingots used in the production of electrical conductors?

- The production of electrical conductors heavily relies on aluminum ingots, which undergo a crucial transformation process. Initially, these ingots are melted and cast into different shapes, including wires, rods, or strips, depending on their intended use. The outstanding electrical conductivity of aluminum is one of the main factors contributing to its widespread use in electrical conductors. With approximately 61% of the electrical conductivity of copper, aluminum serves as a viable alternative in electrical applications. Moreover, its lightweight nature compared to copper offers advantages in terms of transportation and installation costs. To manufacture electrical conductors, the typical procedure involves various steps for processing aluminum ingots. Initially, the ingots are heated and extruded to form elongated aluminum rods or wires. These rods or wires are then drawn through a series of dies to decrease their diameter and increase their length. This wire drawing process refines the microstructure of aluminum, ultimately enhancing its electrical conductivity. Subsequently, the aluminum rods or wires undergo annealing to relieve any stress and enhance their mechanical properties. Following this, a thin layer of insulation, such as a polymer or enamel coating, may be applied to the aluminum conductors. This protective coating safeguards against electrical short circuits and corrosion. Once the aluminum conductors are prepared, they find application in a wide range of electrical uses. Commonly utilized in power transmission and distribution systems, aluminum conductors are frequently employed in overhead lines. Additionally, they are utilized in electrical cables, including building wiring and automotive wiring harnesses. To summarize, aluminum ingots are a vital component in the production of electrical conductors. Through processes like extrusion, wire drawing, and insulation application, aluminum ingots undergo a transformation into dependable and highly conductive components utilized in diverse electrical applications.

- Q: How can the sustainability practices in aluminum ingot production be enhanced?

- The sustainability practices in aluminum ingot production can be enhanced by implementing measures such as increasing energy efficiency, adopting renewable energy sources, reducing waste generation and implementing recycling programs, minimizing water usage, optimizing transportation and logistics processes, and promoting responsible sourcing of raw materials. Additionally, investing in research and development to develop innovative and eco-friendly technologies can further enhance sustainability practices in aluminum ingot production.

- Q: What does nonstandard pure aluminium ingot mean?

- For direct casting, the casting is good in toughness but not in strength and poor in physical properties.

- Q: How can I extract aluminium ingots from cans?

- If you want to sell, small and medium-sized aluminum factory will generally buy, but if you do not remove other components, and direct sell cans on the price is not much difference. When you first start, you certainly have little experience. When you have industry experience, consider whether you want to expand or not, and most importantly, how much you know about the industry.

Send your message to us

Aluminum Pig/Ingot With Best Price From China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches