Aluminum Foil for Baking Cooking Restaurant and Hotel

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 roll

- Supply Capability:

- 10000 roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Structure of Aluminum Foil Description

Aluminum Foil is structured by aluminum paper, which is the raw material .It is suitable for: Tobacco, food, beer, beverage, decoration, electric cable, electrolytic capacitor, medicine and air-conditioner.

Main Features of the Aluminum Foil:

High heat reflection & low thermal conductivity

Heat preservation & energy saving

Moisture barrier & waterproof

Low flammability

Strong, durable & corrosion resistance

Light weight & easy to install

Clean, safe and fibre free & no odour and toxicity, totally environmental-friendly

No mildew growth & no rodent and insect nesting

Application of Aluminum Foil

Heat resistance

packing

electrical industry

general purpose repair

outside electronics product packing with safety material

Advantage of Aluminum Foil

1.superb tack and adhesion to surface, Strong grip that is ensured because of an excellent adhesive backing.

2. Peak performance even under extreme conditions of pressure and temperature, which can stick to all types of surfaces.

3. Consistent quality

4. on time delivery

5. Effective and timely communication

6. Competitive price

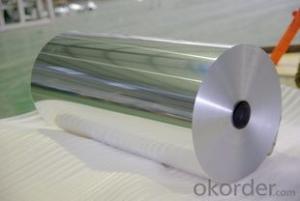

Aluminum Foil Images

Aluminum Foil Specification

| Material | High quality aluminum foil, Food garde, FDA Certificate,100% safe |

| Thickness | 0.009mm-0.022mm |

| width | 100-600mm |

| Length | 3-300m |

| Use age | food wrapping, BBQ, kitchen use, cold storage, cooking, microwave oven use, baking oven use etc |

| Feature | excellent resistance to high and low temperature, -20 to 270 °C accept |

| Package | Individual color box, PP bag or white cellophane paper . We can make the package per customer's design or use our design. |

| Other | Professional factory sale, high quality control, honest price, and good service |

Packing of Aluminum Foil

individually wrapped, shrink, carton.

6rolls/shrink, about 36~100rolls/carton(according to different specifications)

carton size : any carton size as your request

Remarks:

1. The data above are typical results and subject to change without notice.

2. Tolerance: Weight and Thickness: ±10%; Width: ±3mm;

Length: Cut Roll & Log Roll ±0.3m, Jumbo Roll ±0.5%.

3. The products should be stored at room temperature and kept from wet and heat source.

4. It is essential, as with all pressure-sensitive tapes, that the surface to which the tape is applied must be clean, dry, and free of grease and oil.

5. The user should take test and do trial-application on the above products before coming into application so as to witness and ensure suitability for user’s special purpose and technique.

FAQ

1. How long can we receive the product after purchase?

The purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers. Commonly 7 to 10 working days can be served.

2. What's the lead time for delivery?

We ensure you a prompt delivery of the goods. We do not stock any of the goods. The production cycle time of 1*20FCL is 2-3 weeks.

3. Can you accept the cooperation way of OEM?

Upon receipt of formal authorization, we can accept OEM processing.

4. Are you offering only jumbos rolls or slit rolls as well?

We offer Jumbos, logs, and slit rolls. All different sizes are available.

- Q: Aluminum foil and aluminum foil is not the same?

- Aluminum foil and aluminum foil is the same.Also as a foil, aluminum foil, in Hongkong, also known as tin foil, is machined by aluminum foil mill into a sheet thickness below 0.2mm, mainly used for kitchen cooking, food containers, or used to make some simple cleaning materials. Thousands of tons of aluminium foil are used around the world for the protection and packing of food, cosmetics and chemicals.

- Q: Aluminum foil surface, SBS roll multilayer superposition, waterproof effect is good?

- Single sided aluminum foil is a mylar foil, also known as plastic tape. The soft rolling aluminum foil and polyester film as raw material, the dry intaglio compound, to foil Mylar film aging after cutting into rolling. One side is the side of aluminum foil Mylar, with side side insulation, conductive function.

- Q: Can the potatoes be heated by foil, please?

- Of course, things wrapped in aluminum foil can not be heated in microwave ovens.

- Q: Do you want the foil removed from the outlet of the central air conditioner?

- What Dongdong, send a photo come up, I do this line for a few years, do not understand what you say

- Q: Is the aluminum foil used for fresh keeping the better the heat preservation?

- To overcome the ordinary styrofoam brittle deformation, recovery of the shortcomings of the poor. The utility model has the advantages of water separation, moisture proof, shock proof, sound insulation, heat preservation, good plasticity and strong toughness.

- Q: Outdoor camping in East China, with only one foil damp barrier in the tent, plus sleeping bags? Do you need inflatable mats?

- Aluminum foil are called moisture-proof pad is completely unscrupulous businessmen gimmick. Sit still, sleep really uncomfortable, from warmth and moisture, almost ignored. If you are in a tight position, buy PURELAND's hexagonal foam mat, and if you have plenty of it, buy it yourself. Must not take the body to make fun of, the aluminum foil pad, when I just started playing, all is used to make the ground mat, at that time loves the tent, but absolutely does not have the moistureproof effect.

- Q: How much is the square aluminum foil composite duct produced and installed?

- The raw material is sheet to around 30, plus glue, flange, freight, production, installation, installation accessories

- Q: Where are the aluminum foil lunch boxes used?

- Picnic barbecue is good. Ya Hong aluminum foil lunch box is good. I'm going to buy some baking.

- Q: Can foil foil be put on and off?

- Most of the foil is shiny on one side and the other dull. Aluminum foil for food can be wrapped on both sides, and it is generally recommended to enhance the heat transfer effect with bright bread wrap. Aluminum foil paper is soft and easy to change, like paper, and it doesn't bounce after deformation

- Q: Can I use the foil instead of the baking paper?

- If you bake cookies and the like, you can replace it, but consider the cost. Oh, the foil is a lot more expensive.

Send your message to us

Aluminum Foil for Baking Cooking Restaurant and Hotel

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 roll

- Supply Capability:

- 10000 roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords