Aluminum Coated Strips used for Can tabs 5182H48

- Loading Port:

- Shekou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Aluminum Coated Strips Used for Can Tabs 5182 H48

We professionally produce aluminium coated strips used for can tabs or ring-pulls. During production, we use large wave shear, transverse shear and longitudinal cut system so as to meet different specifications of customers.

Based on ordinary aluminum, we add Mn and Mg, so as to increase tensile strength and elongation. Normally we use 5182, H48 for production.

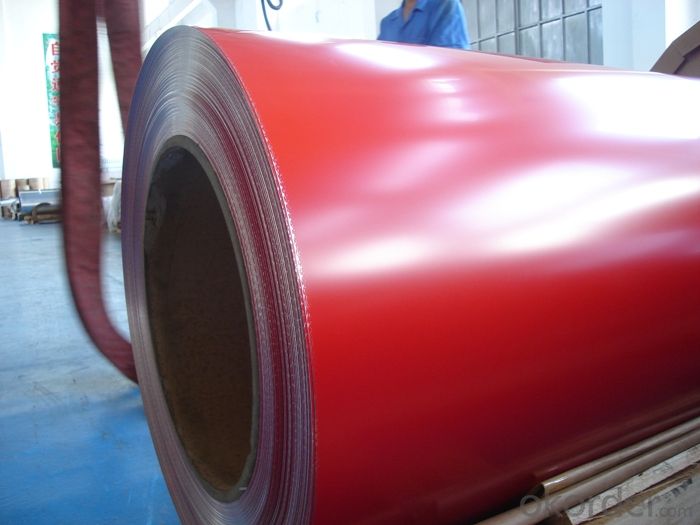

Our coated aluminum strips for tabs are colorful and glossy. We have different colors for tabs, such as blue, red, transparent, etc. We also can adjust coating according to color of customers and offer personalized services.

2. Main Features of Aluminum Coated Strips Used for Can Tabs 5182 H48

• Light Weight

• High Flatness

• Good Weathering

• Colorful

• Recycling

• Saving Energy

• Rustproof

3. Aluminum Coated Strips Used for Can Tabs 5182 H48 Images

4. Specification of Aluminum Coated Strips Used for Can Tabs 5182 H48

ALLOY | TEMPER | THICKNESS | WIDTH | COIL OR LENGTH |

5052 5182 | H19 H36 H48 H49 | 0.22-0.5mm | 500-1600mm | AS PER YOUR REQUIREMENTS |

5. FAQ

A.What about inspections to guarantee quality?

For each order, we will arrange strict inspection for raw materials, inspection during production and inspection for finished goods.

With requirement of customers, we also can arrange the third party inspection.

B.What about delivery?

We will put order in production schedule after order gets confirmed against copy of TT or L/C. Normally it takes about one month for production. Exact shipment schedule is different based on different sizes and quantity.

C.What is the MOQ?

5 tons for each size.

D. Where have you exported?

We have exported to many countries. Main markets include South East Asia, Middle East, North America, South America, etc.

- Q: What characteristics of aluminum strips make them ideal for specific uses?

- <p>Aluminum strips are suitable for certain applications due to their lightweight nature, high strength-to-weight ratio, and excellent corrosion resistance. They are also known for their good thermal and electrical conductivity, making them ideal for heat sinks and electrical components. Additionally, aluminum strips are easily machinable and can be formed into various shapes, which is beneficial for manufacturing. Their non-magnetic properties are advantageous in applications where magnetic interference is a concern. Lastly, aluminum's recyclability and cost-effectiveness make it an environmentally friendly and economical choice for many industrial applications.</p>

- Q: Is it possible to utilize aluminum strips for constructing outdoor decking or railings?

- <p>Yes, aluminum strips can be used for outdoor decking or railings. They are known for their corrosion resistance, low maintenance, and durability, making them suitable for outdoor applications. Aluminum is lightweight, strong, and can withstand various weather conditions without rusting. However, it's essential to ensure that the aluminum is of high quality and properly treated to maintain its performance over time. Additionally, it's crucial to follow proper installation practices to ensure safety and longevity.</p>

- Q: Explain the role that aluminum strips play within the construction of a building.

- <p>Aluminum strips in a building serve multiple functions. They are often used for thermal insulation, helping to reduce heat transfer between the interior and exterior of the building, thereby improving energy efficiency. Aluminum strips also play a role in moisture control by preventing water infiltration, which can protect the building's structural integrity. Additionally, they can be used for aesthetic purposes, adding a modern and sleek appearance to the building's exterior. In some cases, aluminum strips are used in the construction of window and door frames, providing strength and durability while also offering good resistance to corrosion.</p>

- Q: Is it possible to utilize aluminum strips for a personal roofing project?

- <p>Yes, you can use aluminum strips for your own roofing project. Aluminum is a popular choice due to its durability, lightweight, and resistance to corrosion. It's easy to work with and can be cut and shaped to fit various roofing designs. However, it's crucial to ensure proper installation, as aluminum expands and contracts with temperature changes, requiring appropriate fastening and sealing to prevent leaks. Always follow local building codes and consult with a professional if you're unsure about the installation process.</p>

- Q: What types of aluminum alloys are known for their higher resistance to corrosion compared to other aluminum types?

- <p>Yes, certain types of aluminum alloys exhibit greater resistance to corrosion. These include 3003, 5052, and 5083 aluminum alloys, which contain magnesium and manganese, enhancing their corrosion resistance. Additionally, 6061 aluminum, which contains magnesium and silicon, is known for its good resistance to atmospheric corrosion. These alloys are often used in marine environments and other corrosive conditions due to their superior corrosion resistance.</p>

- Q: Can aluminum strips withstand harsh conditions like high humidity or salt spray?

- <p>Aluminum strips can be used in harsh environments to some extent, but their performance may be compromised. Aluminum is resistant to corrosion, making it suitable for high humidity conditions. However, in environments with significant salt spray exposure, aluminum can corrode over time, particularly due to the formation of galvanic cells when in contact with other metals. Protective coatings or anodizing can enhance its corrosion resistance, but it's not entirely impervious. Thus, while aluminum can be used in such environments, it requires proper protection and maintenance to ensure longevity.</p>

- Q: This question asks for an overview of the steps involved in the manufacturing of aluminum components used in vehicles.

- <p>The production process of automotive aluminum parts typically involves several key steps: material selection, design, casting or forging, machining, heat treatment, surface treatment, and quality control. Aluminum is chosen for its lightweight and high strength properties. The design phase involves creating detailed plans for the part. Casting or forging shapes the aluminum into rough forms. Machining refines these forms to precise specifications. Heat treatment enhances strength and durability. Surface treatments protect against corrosion and wear. Finally, quality control ensures each part meets industry standards before it is used in vehicles.</p>

- Q: This question asks about the specific uses of aluminum strips in the automotive industry.

- <p>Aluminum strips are widely used in the automotive industry due to their lightweight and corrosion-resistant properties. They are commonly used in the manufacturing of car bodies, particularly in the doors, hoods, and trunk lids, to reduce weight and improve fuel efficiency. Additionally, aluminum strips are utilized in the production of heat exchangers, radiators, and other cooling systems. They are also found in electrical wiring and connectors due to their excellent conductivity. Furthermore, aluminum strips are employed in the construction of wheels and suspension components, enhancing vehicle performance and durability.</p>

- Q: What are the potential drawbacks or negative aspects of utilizing aluminum strips as a material for exterior siding on a building?

- <p>Aluminum siding, while durable and lightweight, has several disadvantages. It can dent easily due to its softness, which may require frequent repairs. It also lacks insulating properties, leading to increased energy costs as it doesn't retain heat well. Additionally, aluminum siding can be noisy during heavy rain or hail, and it may expand and contract with temperature changes, causing warping or gaps. Furthermore, it can be more expensive than some other materials, and its reflective nature may lead to a less aesthetically pleasing appearance compared to other siding options.</p>

- Q: Is it possible to use aluminum strips for the exterior walls of a building?

- <p>Yes, aluminum strips can be used for exterior walls. They are lightweight, durable, and resistant to corrosion, making them suitable for cladding and facades. Aluminum strips can also be coated with various finishes to enhance their appearance and protect against weathering. They are commonly used in modern architecture for both aesthetic and functional purposes, offering a sleek and contemporary look while providing insulation and weather protection.</p>

Send your message to us

Aluminum Coated Strips used for Can tabs 5182H48

- Loading Port:

- Shekou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords